Metal Oxide Electrochemical Sensors: Revolutionizing the Detection of Microplastics in the Environment

Microplastic pollution has emerged as one of the most critical environmental challenges of our time, particularly threatening aquatic ecosystems globally. These minuscule plastic fragments, often less than five millimeters in size, infiltrate oceans, rivers, and lakes, posing severe risks to marine life and potentially human health through bioaccumulation and food chain contamination. Traditional methods for identifying and quantifying microplastics, such as Fourier transform infrared (FTIR) spectroscopy and Raman spectroscopy, while accurate, involve bulky, complex instrumentation and laborious sample preparation. This complexity hampers their application in quick, on-site environmental monitoring, a crucial need for timely intervention and management.

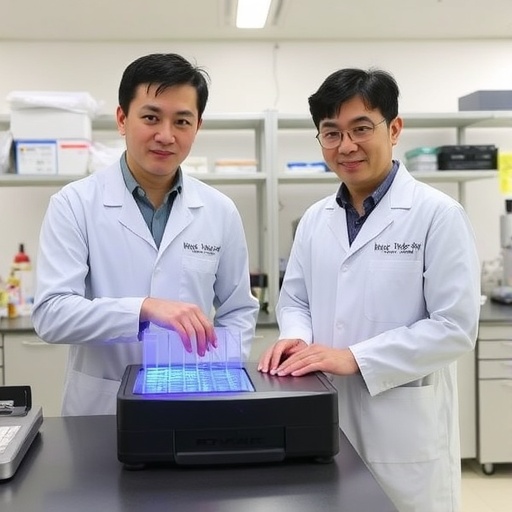

Addressing these limitations, a groundbreaking study led by Professor Sadia Ameen from the Department of Bio-Convergence Science at Jeonbuk National University in South Korea offers a comprehensive review of emerging metal oxide-based electrochemical sensors for microplastic detection. Published in the high-impact journal Trends in Environmental Analytical Chemistry in early 2026, this work delineates a paradigmatic shift towards rapid, cost-effective, and sensitive detection technologies that could transform environmental surveillance frameworks.

At the core of this innovative detection strategy lies the utilization of metal oxide electrodes, which present unique physical and chemical properties ideal for electrochemical sensing. Materials such as zinc oxide (ZnO), titanium dioxide (TiO₂), and cerium dioxide (CeO₂) boast high electrical conductivity coupled with large specific surface areas, enabling enhanced interaction with microplastic particles. These interactions provoke measurable changes in electrical impedance and transient current signals at the electrode interface, providing direct, sensitive indicators of microplastic presence and concentration even within complex environmental matrices like wastewater and seawater.

The research further explores how tailoring the morphology and surface chemistry of metal oxide nanostructures can significantly amplify sensor performance. Morphological modifications—ranging from nanorods and nanowires to hierarchically porous architectures—create localized ‘hotspots’ that intensify the electrochemical response, thereby elevating detection sensitivity beyond what simple spherical nanoparticles can achieve. Surface engineering, such as imparting hydrophobicity to CeO₂ nanoparticles, enhances selective affinity for hydrophobic polymeric microplastics like polyethylene and polypropylene. This selective targeting mechanism is pivotal for discriminating microplastics amidst diverse environmental interferents, a longstanding hurdle in sensor specificity.

Such metal oxide electrochemical sensors are not confined to lab settings; their low power consumption, portability, and rapid response times make them ideally suited for real-time, in situ deployment in environmental and food safety monitoring. Field researchers can employ handheld or wearable sensor devices to conduct routine surveillance of riverine, lacustrine, and marine environments, significantly reducing the time lag between sample collection and result acquisition. Moreover, continuous monitoring protocols leveraging these sensors can facilitate proactive ecosystem management by swiftly detecting microplastic contamination events.

Beyond environmental applications, these sensors have the potential to revolutionize food safety assurance. Detecting trace-level microplastics that evade conventional water treatment processes or contaminate seafood and processed foods is crucial for regulatory compliance and public health. Metal oxide-based electrochemical platforms could become standard tools during food processing and inspection stages, ensuring that microplastic contamination remains within stringent safety thresholds.

On a broader technological front, integrating metal oxide sensor systems with Internet of Things (IoT) frameworks and artificial intelligence (AI) algorithms promises unprecedented advancements in environmental monitoring networks. IoT connectivity can enable real-time data aggregation from distributed sensing nodes, while AI-driven data analytics can enhance pattern recognition, predictive modeling, and rapid decision-making. This confluence of novel material science and digital technologies heralds a new era of smart, automated environmental stewardship that extends beyond microplastics to encompass multifaceted pollution and ecosystem health indicators.

Professor Ameen’s team highlights the criticality of these sensors in risk assessment paradigms, especially linking microplastic pollution to combined chemical exposures. Many hazardous pollutants adsorb onto microplastic surfaces, potentiating synergistic toxic effects in biological systems. The ability of metal oxide electrochemical sensors to detect not only microplastics but also their associated chemicals provides a multifaceted analytical tool for comprehensive environmental and biological risk evaluations.

The study underscores that metal oxide-based electrochemical sensing represents more than a novel detection technique—it forms the cornerstone of an evolving interdisciplinary field marrying nanotechnology, environmental science, materials engineering, and data science. The rapid maturation and widespread adoption of this technology are poised to substantially advance global environmental resilience, climate adaptation strategies, and public health safeguards.

Jeonbuk National University, renowned for its leading-edge research and innovation, especially in artificial intelligence and physical AI systems, is actively fostering this technological transition. The university’s commitment to digital transformation and interdisciplinary collaboration serves as fertile ground for driving the evolution of next-generation microplastic detection platforms towards commercialization and policy impact.

In summary, metal oxide electrodes are charting a new frontier in the electrochemical detection of microplastics. Their distinctive properties enable rapid, sensitive, and selective sensing capabilities critical for real-time environmental and food safety monitoring. As these technologies integrate with IoT and AI, they promise to empower researchers, regulators, and consumers alike with actionable, timely insights. This emerging paradigm not only accelerates scientific understanding of microplastic pollution but also catalyzes broader societal benefits including environmental sustainability, public health protection, and technological innovation.

Subject of Research: Not applicable

Article Title: Metal oxide electrodes: A new frontier in electrochemical microplastic detection

News Publication Date: 1 March 2026

Web References: DOI: 10.1016/j.teac.2025.e00289

References: DOI: 10.1016/j.teac.2025.e00289

Image Credits: Professor Sadia Ameen from Jeonbuk National University, Republic of Korea