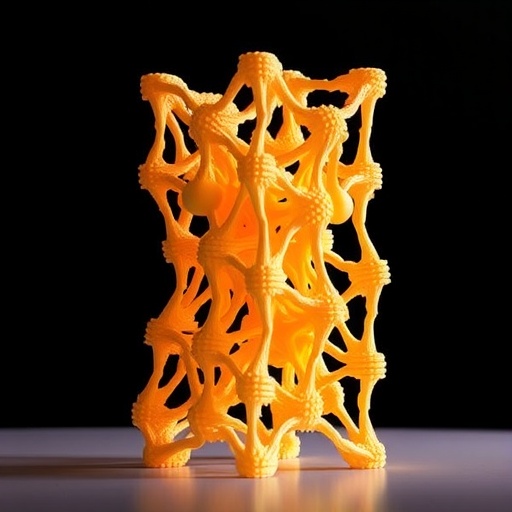

Additive manufacturing, widely recognized as 3D printing, has been revolutionary in the field of manufacturing technologies, providing unprecedented capabilities in fabricating complex geometries with intricate internal structures that traditional manufacturing methods struggle to achieve. By building objects layer-by-layer from a variety of materials including metals, polymers, and biomaterials, this process enables a high degree of design freedom, allowing for customization and prototyping that accelerates innovation across multiple industries.

Yet, despite its transformative potential, the road to fully optimizing additive manufacturing (AM) is fraught with challenges primarily stemming from the intricate relationship between processing parameters and the resulting properties of the fabricated parts. Among these challenges is the complexity of the thermomechanical evolution during the manufacturing process where factors such as laser power, scanning speed, layer thickness, and thermal gradients interact nonlinearly, affecting the microstructure formation and ultimately the mechanical and thermal performance of components.

Parisa Khodabakhshi, an assistant professor of Mechanical Engineering and Mechanics at Lehigh University, is pioneering a new frontier in this domain with her research aimed at bridging these gaps through advanced computational models. Her work addresses the formidable task of predicting microstructural evolution during solidification in binary alloy systems — a critical step in additive manufacturing where the transition from liquid to solid dictates the internal grain structure, phase distribution, and defects influencing the final material properties.

One of the chief obstacles in this endeavor is the high computational cost associated with simulating the multi-scale physics involved in AM processes. The necessity to perform numerous and complex simulations across multiple spatial and temporal scales renders direct computational approaches impractical for design optimization. Khodabakhshi explains this difficulty as the need to establish a comprehensive map that correlates a vast range of process parameters to the eventual material structure—a process hindered by the nonlinear and complex physics involved.

To confront this challenge, Khodabakhshi has secured a substantial three-year grant from the National Science Foundation, amounting to $350,000, dedicated to the development of data-driven, physics-based reduced-order models. These innovative models are designed to drastically reduce computational demands while preserving the integrity of underlying physical phenomena, enabling rapid yet accurate predictions of the solidification microstructure during AM.

Central to Khodabakhshi’s methodology is the concept of the “forward map” — a predictive function that relates specific processing conditions to the resulting microstructure and properties of the manufactured part. However, her research also tackles the inverse problem, which is pivotal for practical manufacturing: determining the precise process parameters necessary to produce a part with targeted mechanical or thermal properties, effectively enabling the optimization of AM processes by reversing the simulation workflow.

This research harnesses the power of scientific machine learning, an emergent field that fuses data-driven techniques with physical laws, ensuring that machine learning models are not simply black-box predictors but are constrained by and respectful of fundamental governing equations. This fusion is vital; it imparts scientific rigor to the predictive models and enhances trust in their applicability to real-world manufacturing scenarios by guaranteeing that outputs remain physically consistent.

In the context of additive manufacturing, such hybrid approaches facilitate modeling complex phenomena like phase transformations, thermal gradients, and microstructure evolution with higher fidelity and efficiency. Leveraging computational mechanics and multifidelity methods, this approach promises to unlock new optimization pathways that could dramatically improve the quality, durability, and performance of AM components.

Industries such as aerospace, automotive, and healthcare stand to benefit immensely from these advancements. In aerospace, for example, the ability to customize lightweight components with optimized microstructures could lead to safer and more fuel-efficient aircraft. Similarly, in healthcare, producing implants with tailored properties could enhance biocompatibility and function. The prerequisite for all these applications is unwavering confidence in the manufacturing process, making predictive and optimized AM indispensable.

Moreover, Khodabakhshi’s initiative exemplifies the broader trend in materials science toward integrating high-performance computing and machine learning to surmount longstanding limitations in modeling complex systems. By embedding physics within learning algorithms and reducing the dimensionality of simulations through reduced-order models, her work exemplifies a critical step toward the democratization of advanced manufacturing designs, bringing sophisticated optimization within reach.

As this research progresses, it not only promises to push the boundaries of additive manufacturing but also reverberates across computational engineering disciplines by demonstrating how the synergy between domain knowledge and data-driven methods can transcend barriers imposed by computational cost and model complexity. The innovations arising from Khodabakhshi’s work may well represent the next leap forward in intelligent manufacturing.

In sum, the convergence of additive manufacturing, computational mechanics, and scientific machine learning as spearheaded by Parisa Khodabakhshi offers a transformative framework for predictive modeling in materials engineering. By developing fast, physically informed reduced-order models to capture the nuances of solidification microstructures in alloys, this work holds the potential to shift AM from an art informed by trial and error to a science guided by precise, optimized decisions—heralding a new era of manufacturing innovation.

Subject of Research: Development of physics-based, data-driven reduced-order models for predicting microstructure evolution in additive manufacturing of binary alloys.

Article Title: Unveiling the Science Behind Optimized Additive Manufacturing: Parisa Khodabakhshi’s Pioneering Approach to Microstructure Prediction

News Publication Date: [Not specified in source]

Web References:

- Lehigh University: Parisa Khodabakhshi Faculty Profile

- NSF Award Abstract: CDS&E: Development of Data-Driven Physics-Based Reduced-Order Models for the Solidification Process of Binary Alloys (2450804)

- Lehigh University Institute for Data, Intelligent Systems, and Computation (I-DISC)

Image Credits: Lehigh University

Keywords

Additive manufacturing, computational mechanics, binary alloy solidification, scientific machine learning, reduced-order modeling, microstructure prediction, materials engineering, process-structure-property relationship, thermomechanical properties, machine learning integration, data-driven modeling, manufacturing optimization