In the rapidly evolving landscape of advanced manufacturing, a groundbreaking study has emerged, illuminating new pathways for fabricating high-performance steels with unprecedented precision. The research, led by Davidson, Le, Nguyen, and colleagues, delves into the intricate phase transformations within high-carbon low alloy steels subjected to laser powder bed fusion (LPBF), a leading additive manufacturing technique. Published in the prestigious npj Advanced Manufacturing in early 2025, this work unravels the nuanced choreography of microstructural evolution driven by controlled laser processing—a feat that could reshape the future of metallurgical engineering and industrial applications.

At the heart of this investigation lies the enigmatic nature of phase formation in steels that contain elevated carbon content paired with low alloying elements. Traditionally, manipulating phase distributions in such steels has been a formidable challenge because rapid cooling rates and thermal gradients during processing often yield heterogeneous microstructures. The team’s research tackles this issue head-on by harnessing LPBF to localize energy input meticulously, thus tailoring the thermal histories at the microscale. This precise thermal management unlocks tailored phase assemblies that were previously unattainable through conventional manufacturing methods.

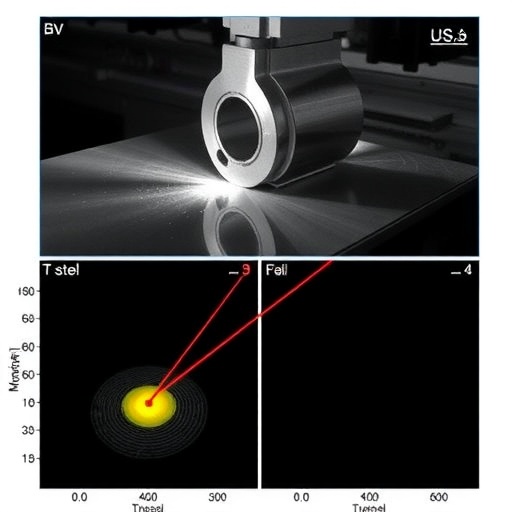

Laser powder bed fusion, renowned for building complex metal parts layer-by-layer from powder feedstock, offers unique advantages in thermal control but simultaneously introduces complex solidification dynamics. In high-carbon low alloy steels, these dynamics dictate phase nucleation and growth, profoundly influencing mechanical properties such as hardness, toughness, and wear resistance. Through rigorous experimentation and state-of-the-art characterization techniques, the research elucidates how variations in laser parameters directly influence phase stability and transformation pathways.

Central to their findings is the ability to induce localized phase control within the material’s microstructure. By modulating parameters such as laser power, scanning speed, and hatch spacing, the team demonstrates that it is possible to engineer regions dominated by desirable martensitic phases while suppressing unwanted brittle carbides or retained austenite. Such spatially resolved phase engineering enables the fabrication of steels with region-specific performance characteristics, effectively marrying toughness and hardness in a single component without resorting to post-processing heat treatments.

Moreover, the study advances a fundamental understanding of rapid solidification phenomena unique to LPBF. By integrating in-situ thermal measurements with microstructural mapping, the authors present an unprecedented view of how temperature gradients and solidification front velocities govern the competitive formation of phases. Their insights extend beyond empirical observations, contributing valuable predictive models that link process parameters with microstructural outcomes, thereby enabling process optimization at the design stage.

The implications of this research extend across diverse sectors where high-performance steels are essential—from automotive and aerospace to tooling and energy infrastructure. The localized control demonstrated here not only enhances mechanical reliability but also promises significant material savings by minimizing defects and reducing the need for alloying additions. Customizing phase content at micron-scale dimensionality could spur the creation of functionally graded materials tailored for complex load-bearing environments.

In an era where sustainability is paramount, the environmental benefits of such manufacturing innovations are noteworthy. LPBF’s additive nature inherently reduces material waste, and the elimination of secondary heat treatments cuts energy consumption dramatically. By perfecting the processing window for high-carbon low alloy steels via this method, the research supports the shift towards greener manufacturing without compromising on material integrity or performance.

The researchers also tackle the challenges posed by residual stresses and distortion—a common obstacle in additive manufacturing of steels. Their localized thermal control mitigates thermal gradients that often lead to warping, ultimately improving dimensional accuracy and structural integrity. This breakthrough enhances the viability of LPBF-produced steel components in critical applications where precision and reliability are non-negotiable.

The study further exploits advanced microscopy and electron backscatter diffraction (EBSD) to map phase distributions with high spatial resolution. These microstructural characterizations reveal the nuanced interplays between laser-modulated cooling rates and carbon partitioning, shedding light on carbide precipitation phenomena and their suppression strategies. The combination of these analytical techniques with process simulation embodies a holistic approach that bridges fundamental metallurgy with practical manufacturing considerations.

Notably, the team employs machine learning algorithms to interpret vast datasets arising from experimental trials, accelerating the identification of optimal process parameters. This integration of artificial intelligence not only expedites research but also sets a precedent for data-driven additive manufacturing, fostering adaptability and continuous improvement in industrial settings.

Looking to the future, this research opens avenues for exploring other alloy systems where phase complexity poses manufacturing challenges. The fundamental principles demonstrated here could be extended to nickel-based superalloys, titanium alloys, or advanced high-strength steels, significantly broadening the scope of LPBF’s applicability. The synergy of localized phase control and additive manufacturing paves the way for next-generation materials with tailor-made properties previously confined to theoretical studies.

Industry stakeholders are poised to benefit from these developments, gaining competitive advantages through rapid prototyping and novel product designs achievable only through such precise metallurgical engineering. The capacity to produce components with spatially varied microstructures heralds a paradigm shift, enabling multifunctional parts that optimize performance and lifecycle costs.

In summary, the work of Davidson and colleagues represents a milestone in additive manufacturing and steel metallurgy. By unlocking localized control over phase formation in high-carbon low alloy steels via laser powder bed fusion, they have charted a course toward materials with unrivaled customization and performance. Their findings not only deepen the scientific understanding of phase transformations under extreme processing conditions but also lay practical foundations for the industrial realization of superior steels.

As additive manufacturing continues its ascent from prototype tool to mainstream production method, studies such as these illuminate the path forward, emphasizing the importance of microstructural engineering in material innovation. This research exemplifies the fusion of advanced characterization, predictive modeling, and process control that will continue to revolutionize how metals are designed and fabricated in the 21st century.

Ultimately, the convergence of metallurgical science and laser-based fabrication technology as demonstrated in this study heralds a new era where complex materials can be engineered from the ground up with atomistic precision. As industries grapple with increasing demands for performance, sustainability, and customization, the techniques revealed here offer a vital toolkit to meet those challenges head-on.

Subject of Research: Localized phase control and microstructural engineering in high-carbon low alloy steels through laser powder bed fusion additive manufacturing.

Article Title: Localised control of phase formation in a high-carbon low alloy steel by laser powder bed fusion.

Article References:

Davidson, K.P., Le, T.P., Nguyen, L.L. et al. Localised control of phase formation in a high-carbon low alloy steel by laser powder bed fusion. npj Adv. Manuf. 2, 11 (2025). https://doi.org/10.1038/s44334-025-00022-3

Image Credits: AI Generated