In a groundbreaking advancement poised to revolutionize the lithium-ion battery industry, researchers at the Institute of Science Tokyo have developed a novel quasi-solid electrolyte known as 3D-Slime Interface Quasi-Solid Electrolyte, or 3D-SLISE. This innovative material ushers in a new era of battery design by combining safety, performance, and sustainability in a way previously thought unattainable. By employing a borate-water-based matrix that simplifies manufacturing and enables direct recycling, the team’s breakthrough could significantly mitigate the environmental and safety concerns that have long constrained the widespread adoption of lithium-ion technology.

Lithium-ion batteries, the cornerstone of modern portable electronics and electric vehicles, have traditionally grappled with critical challenges: flammability risks from organic solvents, energy-intensive production processes, and complicated recycling protocols. Currently, the reliance on volatile organic electrolytes demands strict, resource-heavy manufacturing environments such as dry rooms and glove boxes, inflating production costs and environmental footprints. Furthermore, the complex binders and electrolyte formulations used complicate recycling, often rendering valuable materials unrecoverable. The 3D-SLISE system directly addresses these pain points by presenting a safer, greener alternative without sacrificing performance.

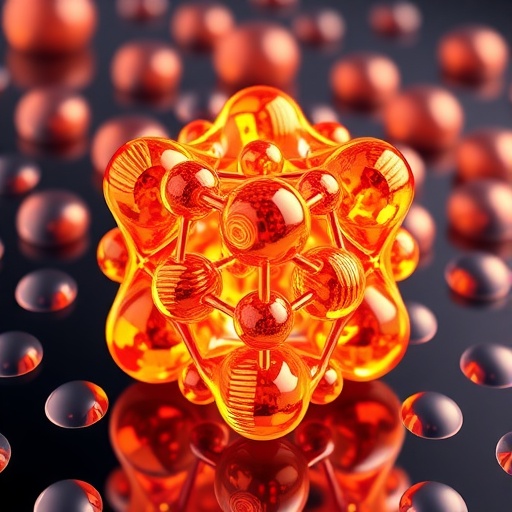

The core of this innovation is a borate-water electrolyte created from amorphous lithium tetraborate combined with a lithium salt, carboxymethyl cellulose, and water. This concoction forms a unique slime-like quasi-solid interface, establishing a three-dimensional ion conduction network that facilitates multidirectional lithium ion mobility. Unlike traditional liquid or solid electrolytes that conduct ions in limited pathways, 3D-SLISE’s isotropic conduction enhances ionic conductivity, reaching values of approximately 2.5 milli-siemens per centimeter. Such conduction efficiency rivals advanced aqueous electrolyte systems while operating effortlessly at ambient temperature, thanks to its low activation energy of 0.25 electron volts.

Fabrication processes further emphasize the sustainability of this system. The slurries constituting 3D-SLISE are naturally dried at room temperature, a stark contrast to the high-temperature or low-humidity conditions demanded by conventional batteries. This ambient fabrication eliminates the need for energy-expensive infrastructures, enabling battery assembly in standard air conditions. Two distinct slurry types are employed: Type E, which integrates with key lithium-based active materials—including lithium cobalt(III) oxide as the cathode and lithium titanate as the anode—to form electrodes, and Type S, which composes the quasi-solid electrolyte layer. The seamless assembly under benign conditions heralds large-scale manufacturability without compromising material integrity.

Performance metrics of batteries utilizing 3D-SLISE are nothing short of remarkable. The assembled cells deliver a stable voltage of 2.35 volts at a 1C rate and consistently sustain over 400 charge-discharge cycles at 3C rates under room temperature, translating to rapid charge and discharge times—around 20 minutes per full cycle. These capabilities indicate that despite being quasi-solid and water-based, the electrolyte competes effectively with, and in some respects outperforms, traditional lithium-ion systems dependent on hazardous organic components. Such battery endurance alongside quick cycling makes 3D-SLISE an optimally practical solution for diverse applications spanning from consumer electronics to grid-scale energy storage.

Beyond performance, the recycling advantages are transformative. Common binders used in lithium-ion batteries, such as polyvinylidene difluoride (PVDF), are challenging to break down, often necessitating harsh chemical treatments. However, 3D-SLISE’s composition excludes these binders and relies solely on water-dispersible components. Used batteries can be dismantled simply by immersing electrodes in water, allowing the active materials—including cobalt, a rare and valuable element—to be directly reclaimed. This straightforward recycling process promises to substantially reduce environmental impact and resource depletion, key attributes aligned with circular economy principles.

The potential environmental benefits extend into the manufacturing chain as well. By circumventing the need for flammable organic solvents, 3D-SLISE considerably reduces fire hazards—a persistent safety concern in lithium-ion battery production and operation. The elimination of dry rooms and glove boxes, which consume significant energy and impose complex operational standards, further reduces the carbon footprint and costs associated with battery fabrication. Collectively, these characteristics place 3D-SLISE as a game-changing technology that aligns industrial scalability with environmental stewardship.

Technically, the incorporation of amorphous lithium tetraborate serves dual functions: it provides a stable structural framework for ion transport and enhances electrochemical stability of the cell. Lithium bis(fluorosulfonyl)imide (LiFSI) salt ensures efficient lithium ion availability, while carboxymethyl cellulose contributes to the desired viscoelastic properties of the quasi-solid matrix. The resulting slime-like interface bridges the gap between solid and liquid electrolyte behaviors, harnessing advantages of both to maximize ionic mobility without compromising safety or manufacturability.

The Institute of Science Tokyo’s commitment to zero-carbon energy technology illustrates the strategic focus underpinning this breakthrough. Spearheaded by Specially Appointed Professor Yosuke Shiratori and Associate Professor Shintaro Yasui, this research is expected to accelerate the transition toward sustainable energy storage by providing practical, scalable technological solutions. Their findings, detailed in the July 2025 issue of Advanced Materials, underscore an interdisciplinary approach, blending materials science, electrochemistry, and environmental engineering.

Looking forward, the adaptability of 3D-SLISE could empower a wide range of battery-dependent technologies. Portable electronics stand to benefit from safer, more durable power sources, while stationary energy storage could leverage the quick charge rates and long cycle life to enhance grid stability and integrate renewable resources more effectively. Furthermore, the ability to avoid toxic solvents and streamline recycling could transform regulatory landscapes, promoting safer consumer products and industry practices globally.

In summary, 3D-SLISE embodies a multifaceted leap forward in lithium-ion battery science. By integrating inherently safe, water-based materials into a quasi-solid matrix capable of high ionic conductivity and manufacturable under ambient conditions, the Institute of Science Tokyo researchers have charted a promising course toward truly sustainable, high-performance batteries. Their discovery not only addresses the immediate challenges of battery safety and environmental impact but also paves the way for a circular battery economy where materials are continuously recovered and reused, reducing waste and dependence on scarce resources.

Subject of Research: Not applicable

Article Title: Borate-Water-Based 3D-Slime Interface Quasi-Solid Electrolytes for Li-ion Batteries

News Publication Date: 9-Jul-2025

Web References: https://doi.org/10.1002/adma.202505649

Image Credits: Institute of Science Tokyo

Keywords

Lithium ion batteries, Electrochemistry, Applied sciences and engineering, Sustainability, Energy, Conservation of energy