In recent advancements within the realm of biomedical engineering, a research team hailing from the McKelvey School of Engineering at Washington University in St. Louis is pioneering the development of bioelectronic hydrogels. This innovative approach aims to replace conventional wearable and implantable devices designed to monitor various biological activities such as heart rate. Traditional devices are typically composed of rigid materials including metals, silicon, plastic, and glass, which necessitate surgical implantation. However, the newly engineered hydrogels promise enhanced flexibility and adaptability within biological systems.

Central to this groundbreaking research are Alexandra Rutz, an assistant professor of biomedical engineering, along with Anna Goestenkors, a fifth-year doctoral student in Rutz’s lab. Together, they have created an array of novel granular hydrogels composed of microparticles. These microparticles, capable of being injected into the body or spread over tissues, can serve multiple purposes, including the encapsulation of cells and the monitoring and stimulation of biological activity. Their findings were recently published in the reputable nanoscience journal, Small, on October 8, marking a significant step forward in this field.

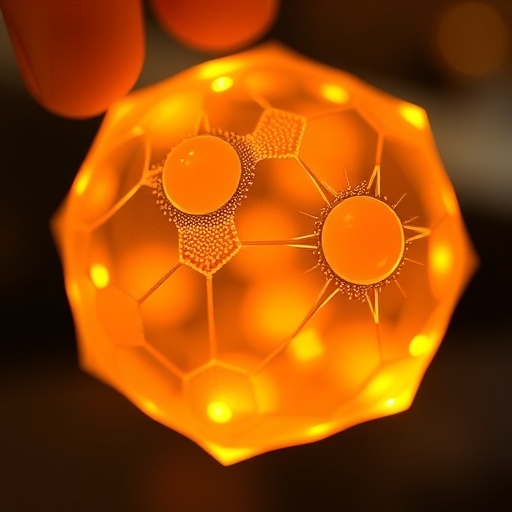

The microparticles in question are spherical hydrogels derived from a conducting polymer known as PEDOT:PSS. When tightly packed, these materials exhibit properties akin to wet sand or paste. This unique structure allows the hydrogels to maintain solidity while incorporating micropores. Furthermore, they can be 3D printed or manipulated into various shapes without losing their structural integrity. When dispersed in liquid, the particles can revert to individual microparticles, showcasing their dynamic nature.

Rutz emphasizes the innovative potential of these granular hydrogels, stating that they have not been extensively studied for bioengineering applications. By borrowing techniques from tissue engineering, the team strives to enable these electrically conductive materials to emulate the properties found within the human body. This ability to mimic biological characteristics while utilizing the functional advantages of the materials opens up new avenues for medical applications and interventions.

One of the most intriguing attributes of this material is its porosity at the microscopic scale, which has profound implications for biological interactions. The spaces between closely packed particles create a porous structure that can facilitate bioactivity on a cellular level. According to Goestenkors, the particles exhibit a degree of movement relative to each other. When a force is applied, the material behaves like a liquid, allowing it to be injected or extruded with ease. Once the force is removed, the particles re-establish connections, reverting to a more solid, paste-like consistency. This inherent adaptability underscores the material’s suitability for biomedical applications, where flexibility is paramount.

In a testament to their practical applications, Rutz and Goestenkors conducted an experiment utilizing locusts. Collaborating with Barani Raman, a professor at McKelvey Engineering and co-director of the Center for Cyborg and BioRobotic Research, they applied small clumps of the granular hydrogel on the tips of locust antennae, regions rich in olfactory receptor neurons. This innovative setup allowed the researchers to measure local field potentials corresponding to odors detected by the locusts, showcasing the hydrogels’ responsive capabilities within living systems.

Imagining the future, Rutz envisions conducting further research with these customizable 3D printed electrodes. The potential for these electrodes to conform to diverse anatomical surfaces and encapsulate biological tissues presents exciting opportunities in tissue engineering and regenerating therapies. This bioelectronic technology could fundamentally reshape how medical diagnostics and treatments are conducted. From prosthetics to neural interfaces, the implications of conducting granular hydrogels extend well into future healthcare innovations.

Additionally, Rutz and Goestenkors are taking tangible steps to protect their intellectual property. They have filed for a U.S. patent that encompasses the fabrication and applications of conducting polymer microparticles along with granular hydrogels. Collaborating with Washington University’s Office of Technology Management, they are navigating the commercialization process, aiming to bring their findings to practical use in medicine and health technology.

The ability of the research team to leverage advances in material science and biomedical engineering collectively demonstrates a forward-thinking vision. It illustrates not only the potential for significant advancements in the field but also the importance of interdisciplinary collaboration in achieving such breakthroughs. The flexibility and capability of granular hydrogels may pave the way for next-generation bioelectronics that more seamlessly integrate with biological systems.

As the development of these bioelectronic hydrogels progresses, the research opens a dialogue about the future of medical technology. Key questions arise about how these new materials can be utilized in various biomedical applications, from real-time monitoring of physiological changes to more effective therapeutic interventions. This research not only represents a synthesis of engineering and biology but also highlights the transformative potential of emerging materials in improving healthcare outcomes.

In conclusion, the development of granular hydrogels by the Washington University research team signifies a pivotal step toward more adaptable and responsive biomedical devices. With capabilities that allow for injectable applications and the emulation of biological structures, this technology can revolutionize monitoring and therapeutic practices in medicine. Continued exploration in this area will undoubtedly uncover even more applications, making a meaningful impact on our approach to health and wellness.

Subject of Research: Bioelectronic hydrogels and their applications in biomedical engineering.

Article Title: Innovative Bioelectronic Hydrogels Set to Revolutionize Biomedical Engineering

News Publication Date: October 8, 2023

Web References: https://engineering.washu.edu/news/2025/Extrudable-hydrogels-act-as-bioelectronic-conductors.html

References: Goestenkors AP, et al. PEDOT:PSS Microparticles for Extrudable and Bioencapsulating Conducting Granular Hydrogel Bioelectronics. Small, Oct. 8, 2025. DOI:

Image Credits: N/A

Keywords

Bioengineering, Biomedical Engineering, Chemical Engineering, Materials Engineering.