The Department of Energy’s Oak Ridge National Laboratory (ORNL) has been honored with the prestigious 2025 SAMPE Organizational Excellence Award, a testament to its groundbreaking advancements in materials science and process engineering. This annual accolade, bestowed by the Society for the Advancement of Material and Process Engineering, recognizes entities exhibiting extraordinary leadership and contributions to the advanced materials community spanning industrial, academic, and governmental spheres. ORNL’s recognition underscores a sustained commitment to pioneering composite materials research and facilitating their accelerated transition from experimental stages to transformative industrial applications.

At the forefront of ORNL’s achievements is its robust portfolio in carbon fiber and composites research – a discipline critical to next-generation manufacturing and material sustainability. Robert Wagner, associate laboratory director for the Energy Science and Technology Directorate, highlights ORNL’s pivotal role in translating laboratory innovations into practical solutions that impact a range of sectors including aerospace, automotive, energy, defense, and infrastructure. This leadership has positioned ORNL not just as a research institution but as a vital hub catalyzing industrial transformation through advanced composite technologies.

Central to ORNL’s research ecosystem are several world-class Department of Energy user facilities, including the Manufacturing Demonstration Facility (MDF), the Carbon Fiber Technology Facility, and the Oak Ridge Leadership Computing Facility. The latter houses Frontier, the world’s first exascale supercomputer, which empowers scientists to undertake atomic-level materials analysis and AI-driven simulations. Such computational prowess is transforming materials engineering by allowing researchers to unravel complex composite behaviors and tailor material properties with unprecedented precision and speed.

The MDF stands out as a national collaborative platform designed to bridge the gap between innovation and commercialization across the manufacturing sector. Supported by the DOE’s Advanced Materials and Manufacturing Technologies Office, this facility facilitates cross-disciplinary partnerships that innovate, inspire, and catalyze the modernization of U.S. manufacturing through cutting-edge material processing and additive manufacturing techniques. By enabling the scale-up of novel composite materials, MDF fosters industrial readiness and accelerates market adoption.

ORNL has been especially influential in the realm of additive manufacturing. By pioneering large-scale additive manufacturing methods that integrate polymers and composites, ORNL is reshaping the possibilities for lightweight structural components. This transformative approach reduces material waste, shortens production cycles, and enables unprecedented design complexity. Such innovations have profound implications for energy efficiency and sustainability, especially in aerospace and automotive industries where weight reduction directly translates to performance gains and reduced emissions.

In complement to additive manufacturing, ORNL is actively advancing the development of cost-effective carbon fiber—a key lightweighting material vital to energy-efficient transportation and infrastructure modernization. Traditional carbon fiber manufacturing has been hampered by high production costs limiting widespread adoption. ORNL’s breakthroughs in creating lower-cost carbon fiber processes are paving the way for broader utilization, thereby helping to lower carbon footprints and enhance energy efficiency across numerous applications.

Thermoset and thermoplastic composites also form a core pillar of ORNL’s research initiatives. The laboratory’s innovative research is unlocking new high-performance materials tailored to specific environmental challenges and application demands. By exploring the molecular and microstructural dynamics of these composites, researchers are engineering materials that offer superior mechanical properties, thermal stability, and durability—key attributes for aerospace and hypersonic vehicle applications where extreme conditions prevail.

The development of extreme-environment composites is another domain where ORNL is trailblazing. The laboratory’s expertise extends to designing materials capable of withstanding the severe mechanical, thermal, and chemical stresses encountered in aerospace and hypersonic regimes. These composites not only improve vehicle performance and reliability but also enhance mission safety and operational longevity—a crucial advance as aerospace agencies and industries push the boundaries of flight speed and altitude.

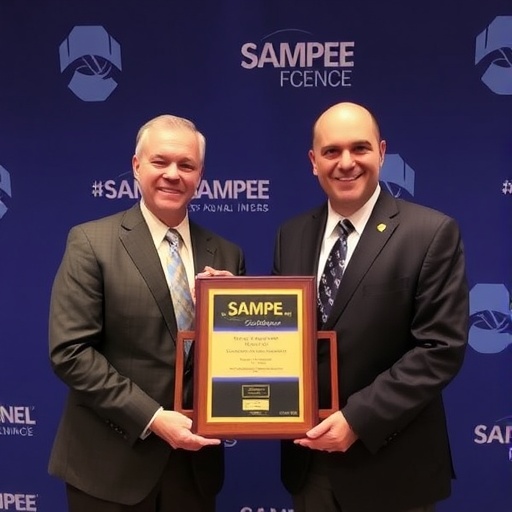

The announcement of this esteemed award took place at the Composites and Advanced Materials Expo in Orlando, Florida, further amplifying ORNL’s visibility among industry leaders and researchers. Vlastimil Kunc, section head for composites science and technology at ORNL, accepted the award on behalf of the laboratory. Kunc’s leadership and vision are instrumental in maintaining ORNL’s position at the cutting edge of composite material science and applications.

Managed by UT-Battelle for the DOE’s Office of Science, ORNL continues to serve as a national nexus for basic scientific research in physical sciences, empowering efforts to solve pressing technological challenges. The Office of Science’s support ensures that ORNL remains equipped with the resources and collaborative environments necessary to sustain innovation across materials science disciplines. This strategic focus aligns with broader national goals centered on energy independence, advanced manufacturing competitiveness, and technological leadership.

The integration of AI and high-performance computing at ORNL marks a new era in materials engineering. The ability to simulate material behavior at atomic and molecular scales accelerates discovery cycles, reduces experimental uncertainties, and guides experimental design towards optimized compositions and structures. This fusion of computation with experimental research enhances the laboratory’s capacity to deliver tailored solutions for complex materials challenges and fosters accelerated technology transfer to industry.

ORNL’s work exemplifies how state-of-the-art facilities and multidisciplinary expertise converge to power the future of materials innovation. From fundamental research in molecular composites to scalable manufacturing demonstrations, the laboratory embodies a model of excellence in scientific collaboration and applied engineering. The SAMPE Organizational Excellence Award not only celebrates past achievements but also signals the laboratory’s pivotal role in shaping the advanced materials ecosystem of tomorrow.

As the advanced materials sector continues to evolve, ORNL’s contributions will remain vital in enabling sustainable, high-performance solutions that address the nation’s industrial and infrastructure needs. Through relentless innovation in carbon fiber production, additive manufacturing, and composite material science, ORNL is pioneering new frontiers that promise to redefine the limits of engineering and manufacturing capabilities for years to come.

—

Subject of Research: Advanced composites materials science and manufacturing technologies

Article Title: Oak Ridge National Laboratory Awarded 2025 SAMPE Organizational Excellence Award for Breakthroughs in Composite Materials

News Publication Date: Not specified

Web References:

– https://www.ornl.gov/facility/mdf

– https://www.energy.gov/science/office-science

Image Credits: ORNL, U.S. Department of Energy

Keywords: Manufacturing, National laboratories, Additive manufacturing, Materials engineering, Materials processing, Materials testing