In recent advancements, flexible pressure sensors have been developed to mimic human skin’s sensitivity, significantly benefiting fields like interactive technologies, health monitoring, and robotics. These innovations leverage a variety of microstructural strategies, including pyramidal, dome, wrinkle, and layered structures, for enhanced sensitivity and durability. Despite their potential, current designs often involve complex manufacturing processes. Addressing these challenges, new approaches aim to simplify sensor fabrication while broadening their pressure detection capabilities and stress tolerance, pushing the boundaries of sensor technology towards more efficient and versatile applications.

A new study (DOI: 10.1038/s41378-023-00639-4) published in the journal Microsystems & Nanoengineering, on February 08, 2024, introduced a cutting-edge flexible pressure sensor renowned for its remarkable resilience to ultrahigh stress. This technological breakthrough harnesses the power of periodic microslits embedded in a composite blend of MW-CNT and polydimethylsiloxane (PDMS), marking a significant advancement in sensor capabilities.

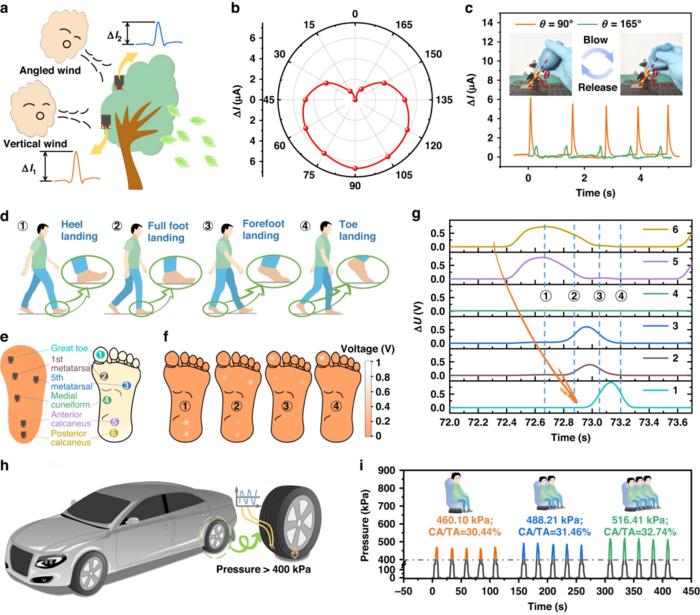

This novel configuration significantly enhances the sensor’s ability to endure extreme pressures, with experimental tests demonstrating a stress tolerance of 400 kPa and theoretical projections reaching as high as 2.477 MPa. Additionally, this design achieves a notable sensitivity of 18.092 kPa−1, setting a new standard for pressure sensor performance. The integration of microslits facilitates substantial deformation under high pressure, broadening the sensor’s operational range while avoiding the complexities of traditional molding and demolding processes. This attribute, coupled with the optimal MW-CNT/PDMS ratio, ensures successive multiple contact points within the sensing film and between the periodic sensing cells when under load. These features collectively enhance the sensor’s efficacy, enabling applications ranging from wind direction monitoring to high-stakes health monitoring and vehicle load detection.

According to the lead researcher, “This innovative microslit strategy not only simplifies the sensor’s fabrication process but also significantly extends its application range, from health monitoring to ultrahigh pressure sensing applications such as vehicle load detection.”

The sensor’s high stress tolerance and sensitivity have vast implications across various sectors, including robotics, health monitoring, and automotive industries. Its ability to detect minute pressure changes opens new possibilities for non-invasive health monitoring devices.

Credit: Microsystems & Nanoengineering

In recent advancements, flexible pressure sensors have been developed to mimic human skin’s sensitivity, significantly benefiting fields like interactive technologies, health monitoring, and robotics. These innovations leverage a variety of microstructural strategies, including pyramidal, dome, wrinkle, and layered structures, for enhanced sensitivity and durability. Despite their potential, current designs often involve complex manufacturing processes. Addressing these challenges, new approaches aim to simplify sensor fabrication while broadening their pressure detection capabilities and stress tolerance, pushing the boundaries of sensor technology towards more efficient and versatile applications.

A new study (DOI: 10.1038/s41378-023-00639-4) published in the journal Microsystems & Nanoengineering, on February 08, 2024, introduced a cutting-edge flexible pressure sensor renowned for its remarkable resilience to ultrahigh stress. This technological breakthrough harnesses the power of periodic microslits embedded in a composite blend of MW-CNT and polydimethylsiloxane (PDMS), marking a significant advancement in sensor capabilities.

This novel configuration significantly enhances the sensor’s ability to endure extreme pressures, with experimental tests demonstrating a stress tolerance of 400 kPa and theoretical projections reaching as high as 2.477 MPa. Additionally, this design achieves a notable sensitivity of 18.092 kPa−1, setting a new standard for pressure sensor performance. The integration of microslits facilitates substantial deformation under high pressure, broadening the sensor’s operational range while avoiding the complexities of traditional molding and demolding processes. This attribute, coupled with the optimal MW-CNT/PDMS ratio, ensures successive multiple contact points within the sensing film and between the periodic sensing cells when under load. These features collectively enhance the sensor’s efficacy, enabling applications ranging from wind direction monitoring to high-stakes health monitoring and vehicle load detection.

According to the lead researcher, “This innovative microslit strategy not only simplifies the sensor’s fabrication process but also significantly extends its application range, from health monitoring to ultrahigh pressure sensing applications such as vehicle load detection.”

The sensor’s high stress tolerance and sensitivity have vast implications across various sectors, including robotics, health monitoring, and automotive industries. Its ability to detect minute pressure changes opens new possibilities for non-invasive health monitoring devices.

###

References

DOI

Original Source URL

Funding information

This work was supported by the National Key R&D Program of China (Grant No. 2022YFB3204800).

About Microsystems & Nanoengineering

Microsystems & Nanoengineering is an online-only, open access international journal devoted to publishing original research results and reviews on all aspects of Micro and Nano Electro Mechanical Systems from fundamental to applied research. The journal is published by Springer Nature in partnership with the Aerospace Information Research Institute, Chinese Academy of Sciences, supported by the State Key Laboratory of Transducer Technology.

Journal

Microsystems & Nanoengineering

Subject of Research

Not applicable

Article Title

Flexible pressure sensors with ultrahigh stress tolerance enabled by periodic microslits

Article Publication Date

8-Feb-2024

COI Statement

The authors declare that they have no competing interests.