In recent years, the global challenge of plastic pollution has become increasingly alarming, with over 400 million tons of plastic produced annually. The environment is suffering due to the consequences of plastic waste, as a mere fraction—approximately 10%—of this waste is recycled. This presents a clear demand for innovative technologies capable of effectively addressing the escalating concerns surrounding plastic disposal and its environmental impact. Among the promising developments in this field is a groundbreaking discovery in catalytic plastic recycling, particularly involving the role of water in enhancing the efficiency of plastic upcycling processes.

Catalytic recycling presents a revolutionary alternative to traditional recycling methods that depend solely on remolding plastic materials. With techniques like hydrogenolysis and hydrocracking, researchers are now unraveling the complexities of transforming plastic waste into valuable chemicals and fuels. This shift not only promotes environmental sustainability but also aligns with the pressing need for advanced recycling solutions that can handle the immense quantities of plastic waste produced globally. However, these catalytic processes, while promising, require significant refinement before they can transition from laboratory settings to industrial applications.

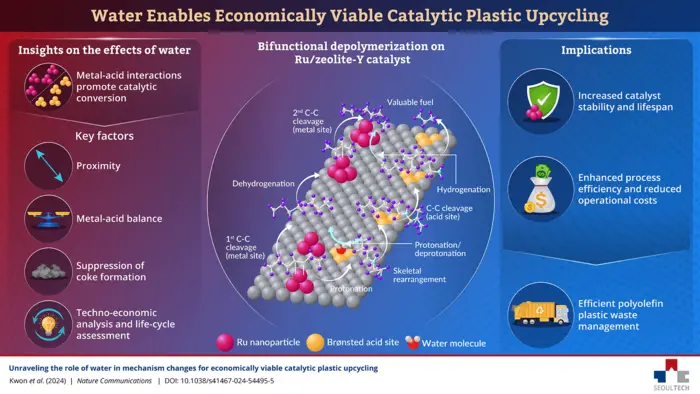

A significant advance in this area was recently published in the journal Nature Communications, detailing a study led by Professor Insoo Ro and his team at the Seoul National University of Science and Technology. Their research focused on polyolefins, the major constituent of global plastic waste, which accounts for approximately 55% of all plastic materials. The critical finding of their study is the beneficial effect of water in the depolymerization of polyolefins when using ruthenium-based catalysts, an effective approach towards optimizing the catalytic recycling process.

In the experiments conducted by the research team, various ruthenium catalysts were synthesized and tested in different configurations and compositions. The results indicated that catalysts featuring both metal and acid sites significantly improved the conversion rates of polyolefins when water was introduced to the reaction mixture. This unexpected outcome reveals that water does not merely act as an inert solvent but plays an active role in changing the dynamics of the reaction.

Dr. Ro emphasized that the addition of water alters the underlying reaction mechanisms. This alteration facilitates the activation of pathways that enhance catalytic activity, all the while mitigating the formation of undesired byproducts. As a result, the process exhibited heightened efficiency, prolonged catalyst lifetime, and diminished operational costs, making it highly favorable for potential industrial applications. Such findings mark a pivotal moment in catalytic recycling technology, highlighting the necessity for further exploration of reaction conditions and catalyst optimization.

Through meticulous investigations, the research team delved into the balance between metal and acid sites on the catalysts, along with the influence of specific ruthenium content. The results demonstrated that under optimal conditions, Ru/zeolite-Y catalysts achieved an astonishing conversion rate of 96.9% for polyolefins. This high level of efficiency paves the way for innovative recycling methodologies that can effectively address the burgeoning amounts of plastic waste.

To ascertain the practical application and commercial viability of this advanced recycling approach, the researchers undertook a comprehensive techno-economic analysis alongside a life cycle assessment. The results clearly indicated that by employing Ru/zeolite-Y catalysts, the recycling process not only enhances carbon efficiency but also contributes positively to both economic and environmental performance metrics. This multifaceted approach underscores the potential of catalytic recycling as a practical alternative to conventional waste management practices.

The implications of these findings transcend mere technical enhancements; they herald a transformative shift in how society approaches plastic waste management. By demonstrating that a sustainable model exists for converting polyolefin waste into valuable resources, this research could drive substantial changes in policy frameworks and inspire investment in advanced recycling infrastructures.

As the research team continues to refine and optimize their methodologies, they aspire to simplify the recycling process even further. Their vision includes a future where mixed plastic waste can be processed without the need for extensive pre-sorting, thereby streamlining recycling efforts across various sectors. Such advancements are crucial in meeting the rising demands for sustainable solutions to mitigate plastic pollution.

Professor Ro’s optimistic outlook on the project is rooted in the potential of their methods to create ripples of change across industries and global communities. He anticipates that the research will align with broader environmental initiatives and promote international collaborations aimed at tackling the plastic waste crisis more effectively. This endeavor reflects a commitment to fostering cleaner environments and developing feasible paths towards sustainable futures.

In summary, this breakthrough in catalytic plastic recycling, particularly the role of water in enhancing catalytic mechanisms, could be the key to revolutionizing our current plastic waste challenges. By reconceptualizing how we manage and recycle plastics, researchers are paving the way for an innovative era of sustainability that addresses one of the most pressing environmental issues of our time.

As the world grapples with the implications of plastic waste, the advancements made by Professor Insoo Ro and his team could potentially change the narrative surrounding environmental responsibility and resource management. The need for continued exploration and investment in such technologies has never been more important as society aims to move towards a sustainable future where plastic consumption does not equate to environmental degradation.

The ongoing research illustrates the power of collaborative scientific inquiry in addressing global challenges. With a clearer understanding of the necessary conditions and mechanisms required for effective recycling, policymakers and investors alike are invited to embrace innovative solutions. This commitment could usher in a new era of responsible plastic use and management, encouraging cleaner ecosystems and reduced instances of pollution.

In light of these advancements, continued support and funding for research in catalytic recycling are paramount. The technological strides made by academic institutions like Seoul National University of Science and Technology not only contribute to the academic field but also serve as vital stepping stones towards global environmental solutions. With hope and dedication, the journey toward a more sustainable future is underway, showcasing the resilience of scientific exploration in combating one of humanity’s greatest challenges.

Subject of Research: Catalytic plastic recycling

Article Title: Unraveling the role of water in mechanism changes for economically viable catalytic plastic upcycling

News Publication Date: 29-Nov-2024

Web References: http://doi.org/10.1038/s41467-024-54495-5

References: 10.1038/s41467-024-54495-5

Image Credits: Insoo Ro of Seoul National University of Science and Technology, Korea

Keywords: Plastic recycling, catalytic processes, environmental sustainability, polyolefins, Ruthenium catalysts, waste management, plastic pollution, techno-economic analysis, innovation in recycling, sustainability, water in catalysis, advanced recycling technologies.