In the relentless pursuit of green energy solutions, a groundbreaking development in industrial hydrogen peroxide (H₂O₂) production has emerged, poised to redefine the efficiency and sustainability of this critical chemical. Researchers Tian, Pei, Wang, and colleagues have unveiled a sophisticated self-breathing electrode that harnesses advanced interface regulation and gradient wettability engineering to enhance electrosynthesis of H₂O₂. Their study, published in Nature Communications, promises to pivot the industrial landscape toward more eco-friendly and energy-efficient methodologies, addressing longstanding challenges in the scalability and environmental impact of hydrogen peroxide manufacturing.

Hydrogen peroxide plays a vital role across diverse industries, from bleaching and disinfection to wastewater treatment and chemical synthesis. Traditionally, its production relies heavily on the anthraquinone process, which involves multiple complex steps, high energy consumption, and significant environmental burdens due to the use of organic solvents and catalyst recycling. Electrochemical synthesis presents an attractive alternative, offering direct, on-demand H₂O₂ production via oxygen reduction reactions (ORR). Yet, overcoming the inherent limitations of electrodes—such as poor oxygen diffusion, limited active site exposure, and low durability—has posed a formidable hurdle.

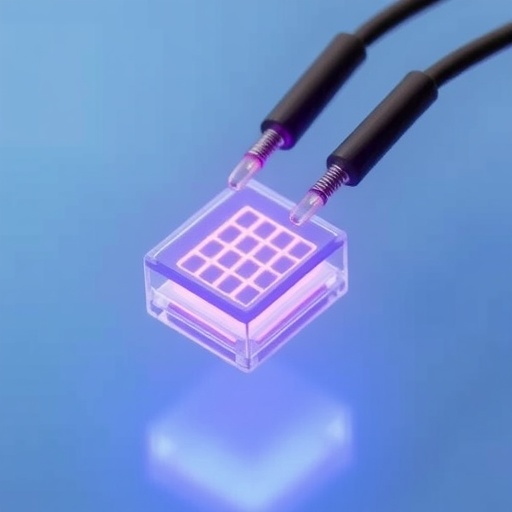

The innovation from Tian et al. centers on the design of a “self-breathing” electrode architecture that dramatically improves oxygen accessibility and reaction kinetics. At the heart of this technology lies a meticulous interface regulation strategy that optimizes electron transfer and enhances catalytic activity while minimizing parasitic reactions. By creating a gradient of wettability—a controlled variation in the surface hydrophilicity and hydrophobicity—the electrode simultaneously facilitates effective oxygen transport and electrolyte interaction, overcoming the diffusion bottleneck that plagues conventional systems.

This gradient wettability engineering achieves a spatially tailored environment. The hydrophobic regions promote oxygen penetration deep into the electrode structure, preventing oxygen starvation during high-current operations. Conversely, hydrophilic zones maintain intimate contact with the aqueous electrolyte, ensuring sufficient corrosion resistance and continuous ionic conduction. The synergy between these contrasting domains not only sustains robust electrochemical performance but also extends electrode longevity, a critical factor for industrial viability.

Through advanced materials synthesis and surface modification techniques, the team fabricated the electrode with precise control over the interfacial properties. Nanoscale characterization revealed a porous network interspersed with strategically placed hydrophobic patches, creating microchannels that facilitate efficient oxygen diffusion while preserving electrolyte wettability. This heterogeneous structure supports a delicate balance between gas accessibility and liquid ion transport, critical for maximizing the four-electron oxygen reduction pathway that selectively produces H₂O₂.

Operating under industrially relevant current densities, the self-breathing electrode demonstrated remarkable Faradaic efficiency, surpassing many previously reported benchmarks. Durability tests further validated the electrode’s stability over prolonged electrolysis without significant performance degradation. Such robustness is essential for scaling up the technology to commercial applications, where operational downtime and maintenance costs pose significant economic challenges.

Beyond the electrode design, the study delves into mechanistic insights that elucidate the influence of interface characteristics on the ORR pathway. Utilizing in situ spectroscopic methods, the researchers exposed how dynamic wettability changes under operational conditions modulate reactive intermediate adsorption and desorption. These findings provide a molecular-level understanding that guides future tailoring of electrocatalysts for selective and efficient H₂O₂ generation.

The implications of this work extend well beyond the immediate scope of hydrogen peroxide production. The principle of gradient wettability engineering can be generalized to other electrochemical systems where gas-liquid-solid interfaces play a pivotal role, such as fuel cells, carbon dioxide reduction, and water splitting. This approach can potentially unlock new avenues for designing multifunctional electrodes with enhanced mass transport and catalytic performance.

Industrial adoption of this technology could yield significant environmental benefits. On-site electrochemical synthesis of H₂O₂ eliminates the need for hazardous transportation and storage of concentrated peroxide solutions, reducing safety risks and associated carbon footprints. Moreover, the process operates under ambient temperature and pressure, offering energy savings over traditional high-temperature, solvent-intensive methods.

Market analysts speculate that integrating such self-breathing electrodes could revolutionize decentralized chemical manufacturing. Small to medium enterprises and remote facilities could produce H₂O₂ on demand, circumventing logistical constraints and tailoring production volumes to specific needs. This decentralization would align with broader trends toward localized, sustainable chemical production enabled by renewable electricity sources.

The study also highlights the role of multidisciplinary collaboration, combining expertise in materials science, electrochemistry, and surface engineering to overcome complex challenges. The integration of computational modeling to predict wettability gradients and experimental validation underscores a holistic approach that accelerates innovation cycles within energy and chemical research domains.

Future research directions include scaling the electrode fabrication processes and integrating the self-breathing electrodes into full electrolyzer assemblies. Additionally, exploring alternative catalyst materials and optimizing pore architectures could further enhance performance and cost-effectiveness. Addressing these challenges will be instrumental in transitioning from laboratory success to widespread industrial deployment.

In conclusion, the pioneering work by Tian, Pei, Wang, and colleagues marks a significant leap forward in the electrosynthesis of hydrogen peroxide, achieved through the ingenious application of interface engineering and gradient wettability tailored for gas-liquid interactions. This advancement not only propels sustainable chemical synthesis but also sets a precedent for the strategic design of next-generation electrocatalysts with broad applicability across sustainable technologies.

The research presents a compelling blueprint for solving long-standing bottlenecks in electrochemical manufacturing, positioning self-breathing electrodes as a cornerstone technology for the green chemical industry of the future. As the global energy transition accelerates, innovations such as this will be vital in delivering scalable, safe, and eco-friendly chemical production methods aligned with circular economy principles.

With its profound implications and potential to disrupt conventional industrial processes, this study is poised to generate substantial interest not only in academic circles but also among chemical manufacturers, environmental policymakers, and clean technology investors worldwide. Such cross-sector engagement is crucial for translating laboratory breakthroughs into real-world solutions that contribute to sustainable development goals.

Emerging from this landmark study is a roadmap for a cleaner, more efficient, and resilient chemical industry, promising to unlock the full potential of electrochemical technologies in shaping a sustainable energy landscape for generations to come.

Subject of Research:

Electrochemical synthesis of hydrogen peroxide employing self-breathing electrodes with interface regulation and gradient wettability engineering.

Article Title:

A self-breathing electrode enabled by interface regulation and gradient wettability engineering for industrial H₂O₂ electrosynthesis.

Article References:

Tian, Y., Pei, L., Wang, S. et al. A self-breathing electrode enabled by interface regulation and gradient wettability engineering for industrial H₂O₂ electrosynthesis. Nat Commun (2026). https://doi.org/10.1038/s41467-026-68436-x

Image Credits:

AI Generated