In a groundbreaking advancement poised to revolutionize the monitoring of high-speed machinery, researchers at Jinan University in China have unveiled an innovative real-time imaging system that captures crystal-clear images of fast-spinning objects over extended periods. This technology promises to transform how turbines, jet engines, and a myriad of rotating components are inspected, offering unparalleled precision in detecting early signs of wear and damage without interrupting operation. The ability to obtain continuous, high-quality images from objects rotating at tens of thousands of revolutions per minute opens new frontiers in predictive maintenance and safety assurance across industries.

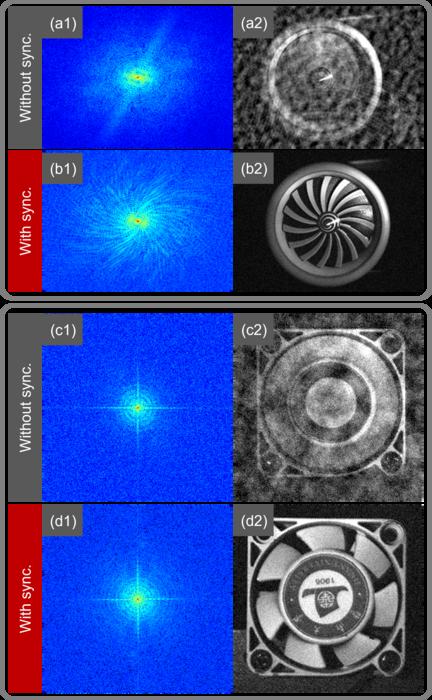

Traditional high-speed cameras, while capable of capturing rapid motion, suffer significant drawbacks including exorbitant costs, bulky designs, and limited operational duration due to heat and data processing constraints. Moreover, they frequently generate blurred or noisy images when tasked with freezing extremely swift rotations. Addressing these challenges, the research team, led by Zibang Zhang, implemented a unique approach that leverages the repeatability of rotational motion rather than brute-force imaging speed. By synchronizing structured light projection with the object’s cyclical movement, the system effectively “freezes” the object in time, enabling high-resolution images reconstructed through innovative computational methods.

At the core of this system lies a single-pixel detector coupled with a digital micromirror device (DMD)-based projector capable of pattern projection rates up to 22,000 Hz. Unlike conventional cameras composed of millions of pixels, this setup relies on a single highly sensitive photodiode. The detector measures intensity variations caused by sequentially projected patterned light onto the spinning object. Each illumination pattern corresponds to a precise snapshot of a rotational phase. Over successive rotations, the composite measurements allow sophisticated algorithms to recover detailed spatial images of the rotating surface, overcoming the paradox of capturing motion without motion blur.

One of the key breakthroughs enabling this high-speed imaging feat is the synchronization mechanism implemented via optical "alarm clocks." The researchers directed a laser beam onto one specific blade of the rotating object, causing periodic backscattered pulses as the blade passed by. Counting these pulses provides an accurate temporal marker correlated to the object’s angular position. Once a full revolution is complete, the system triggers the DMD to switch to the next illumination pattern, resulting in a precisely phase-locked data acquisition sequence. This event-driven synchronization translates the dynamic capture problem into a series of static observations, allowing consistent and sharp imaging.

Testing their system on a model jet engine rotating at approximately 2,170 revolutions per minute and a CPU fan spinning at a staggering 14,700 rpm, the team obtained high-quality still images that clearly reveal the intricate details of the blades and surface textures. This validation confirms that their approach requires no prior information about the object’s geometry or rotational stability, enhancing its robustness across applications. Importantly, the system demonstrates resilience even when the rotation speed varies unpredictably, a critical feature for real-world deployment.

The implications of this technology extend far beyond academic curiosity. Continuous, real-time monitoring of components like turbine blades is crucial to preempt failures that may cause costly downtime or catastrophic accidents. Traditional inspection methods often necessitate halting machinery for manual evaluation, introducing risks and inefficiencies. The new system promises non-intrusive, real-time diagnostics capable of detecting minute cracks, erosion, or surface deformities as they develop under operational stresses, thereby enhancing safety and reducing maintenance costs.

Technically, the imaging method employs structured illumination whereby spatial light patterns – such as Hadamard or sinusoidal bases – are projected and modulate the reflected light from the spinning object’s surface. These modulations are integrated by the single-pixel detector to build spatial information indirectly. This computational ghost imaging approach exploits the correlation between known projected patterns and measured intensities, recovering high-fidelity images from substantially fewer measurements than pixel-by-pixel scanning.

Furthermore, utilizing a single-pixel detector yields several performance advantages. Such detectors boast superior sensitivity across a wide spectral range, enabling imaging under low-light conditions typical in industrial environments. Their broad dynamic range and rapid response facilitate capturing transient phenomena that conventional CMOS or CCD cameras struggle to resolve. The simplicity and cost-effectiveness of this sensor architecture potentially democratize access to high-speed imaging, making it feasible for embedded smart systems rather than only large-scale industrial installations.

The researchers envisage diverse applications, from integration into smart manufacturing platforms where continuous quality assurance is paramount, to embedding in aircraft maintenance procedures that currently rely on periodic downtime inspections. The technology may also find roles in monitoring household appliances such as blenders, fans, or hard drives, contributing to smarter, safer devices by providing real-time feedback on mechanical health. This fusion of optical engineering, computational imaging, and adaptive synchronization opens pathways for active diagnostic systems previously unattainable.

Looking ahead, the team plans to advance the portability and user-friendliness of their prototype, optimizing the system for deployment in operational environments such as actual aircraft engines. Enhancements in miniaturization, robustness against environmental disturbances, and integration with machine-learning algorithms for automated defect detection are anticipated research directions. The synergy of these developments promises to redefine standards for predictive maintenance and asset management in mechanical engineering.

This pioneering work illustrates how rethinking imaging modalities through synergistic hardware-software design can surmount fundamental physical limitations imposed by motion blur and sensor constraints. By harnessing the cyclic nature of rotating objects and fusing it with programmable illumination and single-pixel detection, the researchers have created a real-time, scalable, and precise imaging platform with significant ramifications for industrial safety, efficiency, and innovation.

As industries increasingly move toward automation and smart diagnostics, capturing high-fidelity real-time images of fast-moving components becomes indispensable. This system exemplifies the potential of emerging optical and computational technologies to address such pressing challenges, bridging fundamental optics, aerospace engineering, and machine health monitoring, thereby contributing a landmark advancement to the field of applied physics and engineering.

Subject of Research: Real-time imaging system for fast-spinning objects via single-pixel detection

Article Title: Single-pixel real-time monitoring system for a high-speed rotating object

News Publication Date: 15-May-2025

Web References:

https://opg.optica.org/ol/abstract.cfm?doi=10.1364/OL.555872

References:

S. Long, Z. Zhang, M. Yao, Z. Wu, C. Li, J. Zhong, “Single-pixel real-time monitoring system for a high-speed rotating object,” Opt. Lett. 50, 3449-3452 (2025). DOI: 10.1364/OL.555872

Image Credits: Zibang Zhang, Jinan University in China

Keywords

Optics, Aircraft engines, Technology, Mechanical engineering