In a groundbreaking development for biomedical research and pharmaceutical screening, a team of scientists led by Torchia, Di Sante, and Horda has unveiled a fully automated approach for fabricating cell culture hydrogels using robotic liquid handling systems. Published in the prestigious journal Communications Engineering in 2025, their work heralds a transformative advance with profound implications for high-throughput drug testing and personalized medicine. By combining the precision of robotic automation with the biological complexity of hydrogel matrices, the researchers have successfully tackled longstanding bottlenecks in cell culture fabrication, accelerating experimental workflows at an unprecedented scale.

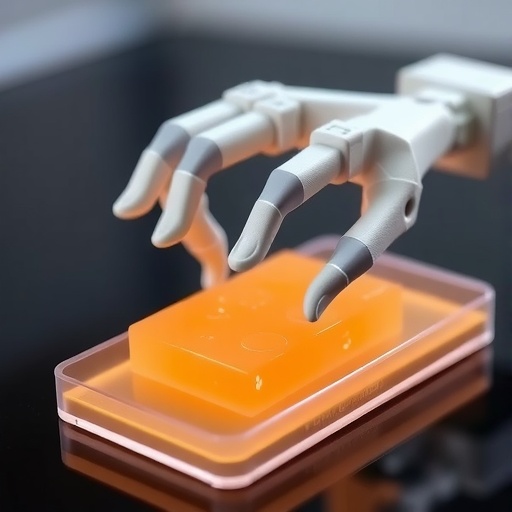

At the heart of this innovation lies the integration of sophisticated robotic liquid handlers capable of dispensing precise volumes of hydrogel precursors and biological components, following meticulously optimized protocols. Hydrogels—three-dimensional, hydrated polymer networks—serve as biomimetic scaffolds that recreate the native extracellular environment of cells far more accurately than conventional two-dimensional cultures. However, manual preparation of these sophisticated matrices is time-consuming, labor-intensive, and prone to variability, factors that limit reproducibility and throughput. The Tordia et al. team circumvented these issues by harnessing automation to standardize hydrogel synthesis while preserving biological fidelity.

The automated platform meticulously regulates parameters such as temperature, mixing speed, pH, and polymer crosslinking kinetics, producing hydrogels with uniform physicochemical properties. This level of control ensures that cell-laden constructs maintain consistent mechanical stiffness, porosity, and diffusion characteristics essential for cellular viability and function. Moreover, the system’s ability to carry out parallelized fabrication of hundreds of individual hydrogel samples empowers researchers to conduct extensive drug screening campaigns rapidly, drastically reducing turnaround times from weeks to days.

Notably, the robotically fabricated hydrogels enable three-dimensional cell cultures that more accurately replicate tissue-specific architectures and microenvironments. This is of paramount importance for drug testing applications since cellular responses often differ drastically between flat, two-dimensional monolayers and three-dimensional settings. By faithfully mimicking in vivo conditions, the hydrogels improve predictive accuracy for pharmacodynamics and toxicity studies. This could ultimately lower drug attrition rates during clinical trials, saving time and resources across the pharmaceutical pipeline.

Furthermore, the use of liquid handling automation allows for precise spatial patterning of cells within the hydrogel matrix, an innovation that opens avenues for recreating complex tissue models. For example, gradients of signaling molecules and co-cultures of multiple cell types can be generated in defined configurations, facilitating studies of cell-cell interaction, migration, and differentiation under controlled conditions. This multi-parameter tunability advances the frontier of tissue engineering and disease modeling.

The fabrication process also leverages advances in polymer chemistry to customize hydrogel compositions tailored to specific cell types or experimental goals. Synthetic polymers such as polyethylene glycol and natural biomaterials like collagen or hyaluronic acid are combined in defined ratios, yielding scaffolds with optimized bioactivity and mechanical properties. The robotic system’s ability to systematically vary formulations accelerates identification of ideal matrix conditions for various applications, fostering a new era of materials discovery driven by automation and high-throughput experimentation.

Quality control is a critical feature embedded within the automated workflow. Integrated sensors and imaging modules continuously monitor hydrogel integrity, homogeneity, and cell viability post-fabrication, ensuring that only samples meeting rigorous standards proceed to downstream assays. This real-time feedback capability markedly improves experimental reliability and reproducibility, addressing a pervasive challenge within in vitro research methodologies.

Additionally, the platform’s software suite supports seamless experimental design, permitting researchers to program complex fabrication sequences without extensive coding expertise. Intuitive user interfaces enable rapid iteration of protocols, while data logging functions facilitate detailed tracking of experimental variables and outcomes. Coupling this with machine learning algorithms has the potential to further optimize hydrogel formulations and culture conditions through predictive modeling based on historical data.

Economically, the automated hydrogel fabrication reduces labor costs and resource consumption by minimizing human intervention and minimizing reagent waste. Automated dispensing ensures accurate volumes, avoiding costly overuse of expensive biomaterials and drugs. This scalability aligns with industrial demands for large-scale screening and could democratize access to advanced culture techniques beyond specialized laboratories.

Importantly, this work paves the way for integrating automated hydrogel culture systems with other high-throughput platforms such as robotic microscopy, multi-well plate readers, and microfluidics. Such interoperability promises end-to-end automated workflows encompassing tissue fabrication, phenotypic assessment, and data analysis—all fundamental to accelerating translational research efforts and precision therapeutics development.

The implications for personalized medicine are particularly inspiring. Patient-derived cells embedded within these reproducible hydrogel matrices could enable ex vivo modeling of individual responses to candidate drugs, facilitating tailored treatment regimens. This paradigm shift towards personalized biofabrication could revolutionize clinical decision-making, increasing efficacy while minimizing adverse effects.

Despite the successes, researchers acknowledge ongoing challenges including scaling towards even higher throughput, expanding the repertoire of compatible cell types, and refining hydrogel properties to better mimic complex tissue mechanics. Continued interdisciplinary collaboration among bioengineers, chemists, roboticists, and biologists will be essential to fully realize the potential of automated hydrogel fabrication in biomedical innovation.

In summary, the study by Torchia, Di Sante, Horda and colleagues introduces a landmark technological platform that marries robotic automation with biomaterial science to produce cell culture hydrogels at scale. This advance mitigates critical limitations of manual fabrication, enhances biological relevance, and accelerates high-throughput drug discovery pipelines. The democratization of standardized, reproducible 3D tissue culture models brought about by this research is poised to substantially impact drug development, disease modeling, and personalized medicine strategies in the near future.

As this technology continues to mature, it promises to redefine conventional paradigms in cell culture by enabling rapid, controlled fabrication of complex tissue-like constructs with minimal human intervention. The convergence of automation, materials science, and biomedical engineering epitomized in this work represents a thrilling frontier in life science research, with vast and far-reaching implications for healthcare innovation. The work sets a new benchmark for how future biofabrication platforms must operate—a seamless blend of precision, scalability, and biological sophistication that will catalyze breakthrough discoveries for decades to come.

Subject of Research: Automated fabrication of cell culture hydrogels for high-throughput drug testing

Article Title: Fabrication of cell culture hydrogels by robotic liquid handling automation for high-throughput drug testing

Article References:

Torchia, E., Di Sante, M., Horda, B. et al. Fabrication of cell culture hydrogels by robotic liquid handling automation for high-throughput drug testing. Commun Eng (2025). https://doi.org/10.1038/s44172-025-00575-3

Image Credits: AI Generated