In the relentless quest for sustainable and energy-efficient wastewater treatment technologies, scientists have long turned their attention to the promising potential of electro-Fenton processes. These processes harness electrochemical reactions to generate highly reactive hydroxyl radicals, capable of degrading a wide spectrum of persistent organic pollutants. However, despite their powerful oxidative capacity and relatively mild operational conditions, traditional electro-Fenton systems have faced daunting challenges that limit their practical application. High costs associated with electrode materials, the requirement for high-purity oxygen supply, catalyst degradation, and the accumulation of sludge have remained significant obstacles. Now, groundbreaking research introduces a transformative approach that merges cost-effective materials and innovative electrochemical strategies to overcome these hurdles, heralding a new era in wastewater remediation.

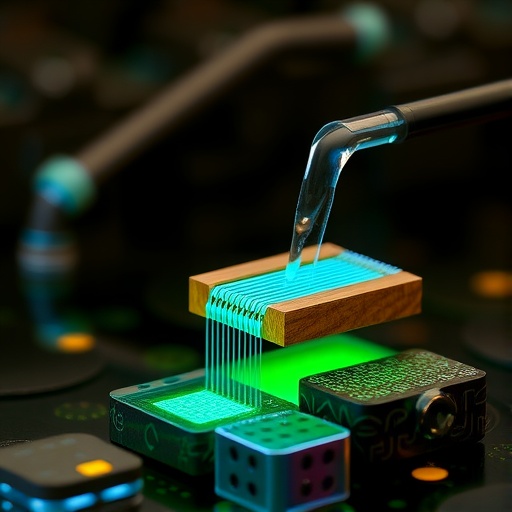

At the heart of this breakthrough is the development of a self-supporting wooden electrode, meticulously engineered to function as a low-cost, environmentally friendly, and highly efficient catalyst. Constructed through a refined process of controlled wood delignification followed by carbonization, this novel electrode exhibits a porous and functionalized architecture optimized for gas diffusion and catalytic activity. The natural microstructure of wood, once stripped of lignin and heat-treated, reveals a three-dimensional network that not only supports catalytic reactions but also facilitates the efficient capture and reduction of oxygen directly from ambient air. This negates the traditional dependence on expensive, high-purity oxygen inputs, dramatically reducing operational costs.

The electrochemical mechanism that powers this system rests on the electro-Fenton reaction, wherein oxygen molecules are reduced to hydrogen peroxide, which, in the presence of iron ions, forms powerful hydroxyl radicals capable of attacking organic contaminants. What distinguishes this wooden electrode system is its ability to enable a two-electron oxygen reduction pathway, efficiently converting oxygen from air into hydrogen peroxide in situ. This feature capitalizes on the electrode’s tailored surface chemistry and porous network, maximizing the catalytic interface available and enhancing mass transport phenomena pivotal for sustained reactivity.

A particularly ingenious innovation of this platform is the application of periodic positive voltage pulses during operation. These pulses periodically restore iron species directly on the electrode surface through electrochemical reduction, effectively regenerating Fe(II) from Fe(III) states within the catalytic interface. This continual regeneration prevents iron from accumulating as inactive deposits on the electrode surface, a common issue causing catalyst deactivation and sludge formation in conventional systems. By maintaining active iron cycling and minimizing surface fouling, the electrode self-refreshes, preserving performance over extended periods without the need for external catalyst replenishment or complex regeneration steps.

Scaling up laboratory innovations often poses significant challenges; however, this wooden-pulsed electro-Fenton system demonstrates impressive stability and operational longevity across an extended duration. In scaled-up trials focusing on bisphenol A degradation—a notorious endocrine-disrupting compound prevalent in industrial effluents and consumer products—the system maintained a consistently high removal efficiency across 30 days of uninterrupted operation. Remarkably, this was achieved at an exceptionally low electrical energy consumption rate of approximately 0.013 kilowatt-hours per gram of bisphenol A degraded, underscoring the technology’s potential for energy-conscious wastewater treatment applications.

The implications of this research extend beyond efficiency metrics. Employing wood—a renewable, biodegradable material—as the substrate for the electrode represents a paradigm shift toward sustainable resource utilization within advanced water treatment technologies. The fabrication process leverages nature’s inherent structural complexity, transforming it through controlled chemical and thermal modification into a high-performance electrocatalyst. This approach not only minimizes reliance on scarce or toxic materials but also points toward scalable manufacturing potential using abundant biomass resources.

This novel system also addresses a critical environmental concern related to wastewater treatment—the generation and handling of sludge. Traditional electro-Fenton systems often produce significant solid residues due to iron hydroxide precipitation and catalyst degradation, creating disposal challenges and additional treatment costs. In contrast, the wooden-pulsed electro-Fenton electrode’s self-refreshing capability minimizes such sludge formation by maintaining iron in its active forms and preventing excessive accumulation on the electrode surface. This translates into a cleaner treatment process with reduced secondary pollution risks and lower operational complexity.

The research team’s strategic combination of material science and electrochemical engineering offers a blueprint for next-generation wastewater treatment technologies that harmonize efficiency, cost-effectiveness, and sustainability. The incorporation of pulsed excitation—a dynamic electrical modulation technique—introduces a novel operational paradigm that could inspire innovations in other areas of electrocatalysis and environmental remediation. Pulsed voltage application dynamically alters interfacial conditions and catalytic states, fostering continuous regeneration and enhanced longevity that may prove transformative when adapted to other reactive systems.

Furthermore, the choice of bisphenol A as a target pollutant in this study highlights the system’s capability to handle persistent organic micropollutants. Bisphenol A is emblematic of a class of compounds resistant to conventional biological or chemical treatment methods, underscoring the urgent need for effective alternative technologies. The demonstrated continuous removal of bisphenol A without performance loss over extended cycles heralds a significant stride toward practical deployment scenarios where long-term stability and reliability are paramount.

This research also provides critical insights on the integration of ambient air, rather than purified oxygen, into advanced oxidation processes. The direct utilization of oxygen from the atmosphere not only simplifies engineering design and operating logistics but also greatly reduces costs associated with gas supply infrastructure, making advanced oxidation processes accessible for decentralized or resource-limited treatment facilities. This novel oxygen supply strategy, paired with enhanced oxygen capture at the electrode interface, offers a compelling model for future sustainable water treatment innovations.

While challenges remain, such as optimizing electrode fabrication for large-scale manufacturing and ensuring consistent performance across varying wastewater matrices, this wooden-pulsed electro-Fenton approach represents a significant leap forward. It embodies the convergence of novel material design, green chemistry, and electrochemical innovation, potentially redefining practical strategies for addressing global water pollution and resource sustainability challenges.

Looking ahead, the underpinning principles demonstrated here could extend to other advanced oxidation processes or environmental electrocatalysis applications, such as air purification, soil remediation, or electrochemical synthesis. The versatility inherent in the wood-derived electrode platform and the pulse-driven electrochemical modulation offers a fertile ground for cross-disciplinary innovation and technology transfer.

In conclusion, this pioneering work showcases that with intelligent integration of natural materials and dynamic electrochemical control, we can overcome longstanding limitations in electro-Fenton wastewater treatment. It opens a promising pathway toward more accessible, sustainable, energy-efficient, and robust treatment technologies vital for safeguarding water quality in a rapidly industrializing and increasingly polluted world.

Subject of Research: Electro-Fenton wastewater treatment; electrocatalysis; sustainable water treatment technologies; wooden electrodes; advanced oxidation processes.

Article Title: Pulse-driven electrocatalysis with engineered wooden electrode for high-efficiency, energy-saving and sustainable water treatment.

Article References:

Zhong, S., Zhou, H., Ren, S. et al. Pulse-driven electrocatalysis with engineered wooden electrode for high-efficiency, energy-saving and sustainable water treatment. Nat Water (2025). https://doi.org/10.1038/s44221-025-00466-z

Image Credits: AI Generated