In a groundbreaking advancement poised to revolutionize the plant-based food industry, researchers have unveiled the pivotal role of cellulose’s degree of polymerization in crafting highly textured, anisotropic meat analogs. This latest study sheds light on the intricate pathways by which cellulose contributes to replicating the fibrous texture reminiscent of animal meat, cultivating textures in plant-based products that could potentially surpass conventional expectations. The implications for consumers seeking plant-based alternatives are profound, promising a future where taste, texture, and nutritional quality converge seamlessly.

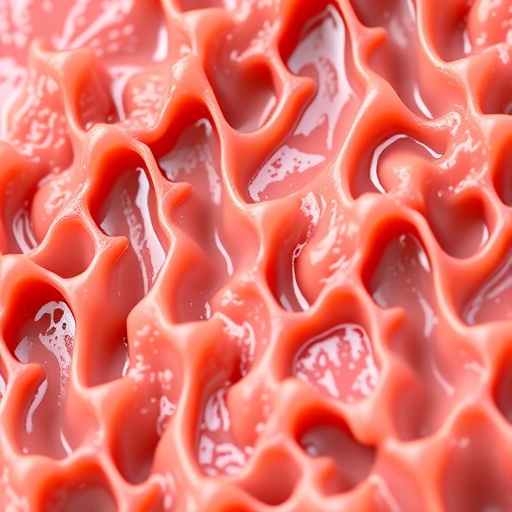

At the heart of this research lies the concept of anisotropy—the directional dependence of properties—which in the context of meat analogs translates to the alignment and structure of protein and fiber matrices. Unlike isotropic substances whose properties remain uniform in all directions, anisotropic textures in meat contribute to the characteristic chew and mouthfeel that define carnivorous delights. The new findings elucidate how cellulose, a key plant polysaccharide, governs anisotropy, influencing the mechanical and sensory perception of these high-moisture structured foods.

Cellulose’s degree of polymerization (DP)—the number of glucose monomer units linked in its polymer chain—emerges as a central variable in determining the textural outcomes of meat analogs. Through meticulous experimentation, the researchers demonstrated that cellulose with higher DP values fosters a more robust network formation within plant protein matrices. This enhanced network evidently facilitates better alignment under shear forces during processing, yielding products with superior fibrousness and anisotropic characteristics.

Such intricate manipulation of cellulose’s polymerization degree not only impacts textural fidelity but also offers a pathway to optimize moisture retention within the matrix. High-moisture meat analogs rely heavily on balancing water content to mimic juiciness and tenderness; the cellulose framework’s ability to entrap and stabilize water molecules is therefore critical. Insights from this study reveal that longer cellulose chains promote intricate water-binding networks which fundamentally enhance the succulence of the final product.

Significantly, the work integrates advanced rheological assessments underscoring how cellulose’s molecular attributes modulate viscoelastic properties during extrusion—a dominant manufacturing technique for meat analogs. By fine-tuning cellulose characteristics, researchers can now predictably engineer the flow behavior of mixtures, ensuring consistent texture reproducibility across large-scale production. This marks a vital step toward industrial scalability of high-moisture textured meats derived from plant sources.

Furthermore, the study addresses the often-overlooked interplay between cellulose and other plant protein constituents such as soy or pea protein isolates. It was found that cellulose with an optimal polymer length acts synergistically, reinforcing the protein network through physical entanglement and hydrogen bonding. This interaction culminates in a cohesive matrix capable of sustaining anisotropic architectures even under thermal and mechanical stresses encountered during cooking or handling.

From a structural biology perspective, the research deciphers the micro- and nano-scale arrangements within the meat analog matrix via imaging techniques and spectroscopy. The visualization of cellulose polymer chains interspersed between protein fibrils reveals mechanisms of fiber reinforcement at the molecular level. Such insights demystify longstanding challenges faced in replicating native muscle fiber structure in plant-based foods.

The environmental stakes of this research cannot be overstated. Plant-based meat alternatives already offer a path to reduced greenhouse gas emissions and lower resource consumption compared to animal husbandry. Enhancing product quality through cellulose polymerization advances consumer acceptance, potentially accelerating the shift toward sustainable dietary patterns. In this sense, the study contributes not only to food science but to global ecological goals.

Moreover, this research outlines the potential for tailored cellulose sources—derived from various agricultural by-products—to be optimized for specific polymerization degrees. This valorization strategy could simultaneously address food waste and supply chain sustainability issues, creating circular economies in plant-based ingredient sourcing. As cellulose is abundant and renewable, these findings open novel avenues for green chemistry innovation.

Notably, the researchers employed a multidisciplinary approach combining polymer chemistry, food engineering, and sensory analysis to achieve these results. Such integrative methodologies reflect the evolving landscape of food science where interdisciplinary collaborations yield transformative breakthroughs. The convergence of expertise ensured that the link between cellulose molecular characteristics and sensory qualities was robustly established.

The study also holds promise for personalized nutrition trends. By modulating cellulose polymer characteristics, manufacturers might adapt meat analog textures to meet diverse consumer preferences—from tender and juicy to firm and chewy. This flexibility enhances inclusivity, catering to varying dietary needs such as elderly individuals requiring softer textures or athletes seeking protein-dense options with specific bite profiles.

Critically, the research underscores the importance of water dynamics within the meat analog matrix. Cellulose’s influence on water mobility, retention, and release during heating processes determines product stability and shelf-life. Understanding these phenomena at the polymer level equips developers with precise control levers to optimize processing parameters and packaging solutions, extending product freshness while maintaining desired mouthfeel.

Looking forward, the implications of this work extend beyond meat analogs to other plant-based textured foods like seafood substitutes and dairy alternatives. The principles established regarding cellulose polymerization and its network formations provide a platform for engineering a new generation of plant-based products with tailored textures and functionalities aligned with consumer expectations.

One challenge acknowledged by the authors is balancing cellulose polymer length with processability; excessively high degrees of polymerization can increase viscosity and processing demands. However, advances in enzyme treatments and controlled polymer degradation may enable fine-tuning of cellulose architecture to reconcile these trade-offs effectively, promising smoother integration into existing production lines.

In conclusion, this pivotal research redefines how the degree of polymerization of cellulose shapes the structural and sensory landscape of high-moisture plant-based meat analogs. Through precise control of molecular parameters, it is now possible to engineer anisotropic textures that closely mimic animal meat, addressing critical hurdles in taste and mouthfeel that have long hindered mainstream adoption. As consumer demand accelerates for sustainable and palatable alternatives, these insights position cellulose not merely as a filler but as a powerful architect of next-generation plant-based foods.

The intersection of polymer science and food technology revealed here marks a new frontier in culinary innovation. By harnessing the structural nuances of cellulose, food scientists can unlock textural realms previously thought exclusive to animal products, heralding an era where plant-based meats are not just alternatives, but preferred culinary experiences. This research thus represents a cornerstone in unlocking the full potential of sustainable nutrition.

Subject of Research: Role of cellulose’s degree of polymerization in influencing anisotropy and texture in high-moisture plant-based meat analogs

Article Title: Role of degree of polymerization of cellulose in governing anisotropy and texture of high-moisture meat analogs.

Article References:

Choi, H., Lee, H., Kim, H. et al. Role of degree of polymerization of cellulose in governing anisotropy and texture of high-moisture meat analogs. Food Sci Biotechnol (2026). https://doi.org/10.1007/s10068-026-02102-2

Image Credits: AI Generated

DOI: 30 January 2026