A novel 3D printing technology developed by Beihang University researchers was able to print multi-material tubular structures with a minimum wall thickness as thin as 50 micrometers and a minimum feature size of 10 micrometers.

Credit: By Huiyuan Wang, Siqin Liu, Xincheng Yin, Mingming Huang, Yanzhe Fu, Xun Chen, Chao Wang, Jingyong Sun, Xin Yan, Jianmin Han, Jiping Yang, Zhijian Wang, Lizhen Wang, Yubo Fan and Jiebo Li.

A novel 3D printing technology developed by Beihang University researchers was able to print multi-material tubular structures with a minimum wall thickness as thin as 50 micrometers and a minimum feature size of 10 micrometers.

The work, reported in the International Journal of Extreme Manufacturing, could someday lead to rapid customization method of tubular grafts and the manufacturing of tubular components in fields such as dentistry, aerospace, and more.

It is challenging for manufacturing complex and delicate radially multi-material model geometries without supporting structures, such as tissue vessels and tubular graft, among others.

“Smooth ultra-thin tubular structures are common in biomedical engineering,” said Jiebo Li, corresponding author on the paper and Professor in School of Biological Science and Medical Engineering, Beihang University.

“It is difficult to manufacture such structures in the traditional Cartesian coordinate system. To better accommodate tubular structures, why not design the 3D printing platform as a cylinder? By adopting a polar coordinate system, rotation, and retraction steps, the manufacturing of these structures can be easy achieved.”

Many advanced 3D printing techniques, with fast printing speed and high precision have been developed in the past several decades. However, none of these techniques are suitable for manufacturing multi-material thin-walled tubular structures.

To achieve varied mechanical properties in multi-material stent printing, researchers utilized Cartesian coordinate-based 3D printing technology, fused deposition modelling (FDM), to manufacture tubular structures. The desired shape is created by printing each layer in x-y plane and stacking different layers in z direction. Nevertheless, the intraluminal stent usually has a large aspect ratio, with tiny tube diameter and long length, making it difficult to stand on the supporting plate stably.

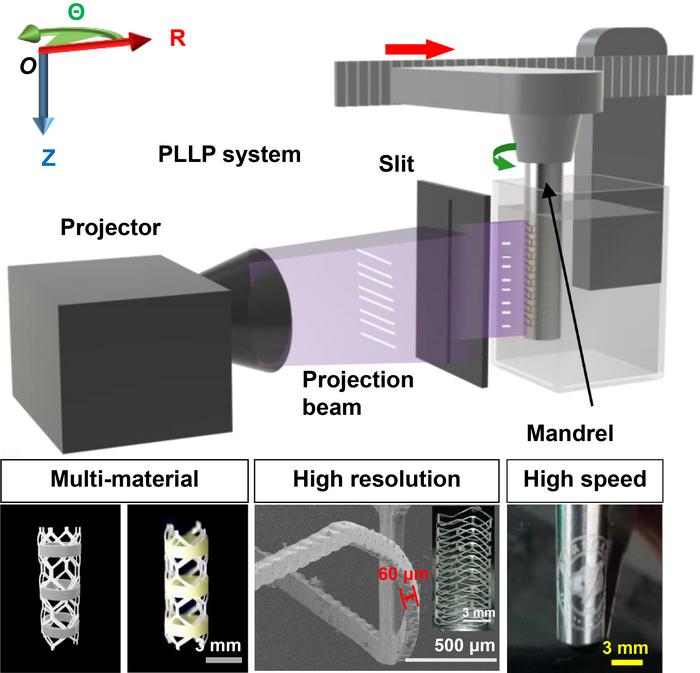

Based on polar coordinate, the BUAA researchers developed a printing setup with a rotating mandrel as the substrate, called Polar-coordinate Line-projection Light-curing Production (PLLP) technology. The patterned light illumination creates tiny solidified polymeric structures on the rotating mandrel.

The researchers utilized PLLP technology to achieve the fabrication of thin-walled multi-material tubular structures. They validated the advantages of PLLP technology over traditional Cartesian coordinate-based 3D printing methods through simulation and mechanical experiments. Additionally, they confirmed the feasibility of printing hydrogel materials.

“The biggest advantage for PLLP is that one can rapidly fabricate smooth-surfaced tubular multi-material structures,” said Professor Li. “This method is particularly beneficial for the swift customization of tubular grafts as well as the manufacturing of tubular components in other fields.”

The researchers are continuing the work, hoping to improve the forming speed and resolution. They aim to apply the PLLP technology to a wider range of fields, such as dentistry and aerospace.

About IJEM:

International Journal of Extreme Manufacturing (IF: 14.7, 1st in the Engineering, Manufacturing category in JCR 2023) is a new multidisciplinary, double-anonymous peer-reviewed and diamond open-access without article processing charge journal uniquely covering the full spectrum of extreme manufacturing.

The journal is devoted to publishing original articles and reviews of the highest quality and impact in the areas related to the science and technology of manufacturing functional devices and systems with extreme dimensions (extremely large or small) and/or extreme functionalities, ranging from fundamental science to cutting-edge technologies that support the manufacturing of high-performance products involving emerging techniques and breaking the limits of currently known theories, methods, scales, environments, and performance.

Visit our webpage, Like us on Facebook, and follow us on Twitter and LinkedIn.

Journal

International Journal of Extreme Manufacturing

Article Title

Polar-coordinate line-projection light-curing continuous 3D printing for tubular structures

Article Publication Date

23-Apr-2024