Scientists from Nanyang Technological University, Singapore (NTU Singapore) and Temasek Polytechnic have successfully replaced half of the fishmeal protein in the diets of farmed Asian seabass with a ‘single cell protein’ cultivated from microbes in soybean processing wastewater, paving the way for more sustainable fish farming practices.

The use of a cultivated protein is new to aquaculture production, say the scientists from the Singapore Centre for Environmental Life Sciences Engineering (SCELSE) leading NTU’s efforts in the study, and Temasek Polytechnic’s Aquaculture Innovation Centre (AIC).

Farmed aquaculture species rely heavily on feed made from wild-caught fish, known as fishmeal, which is not sustainable and contributes to overfishing of the seas.

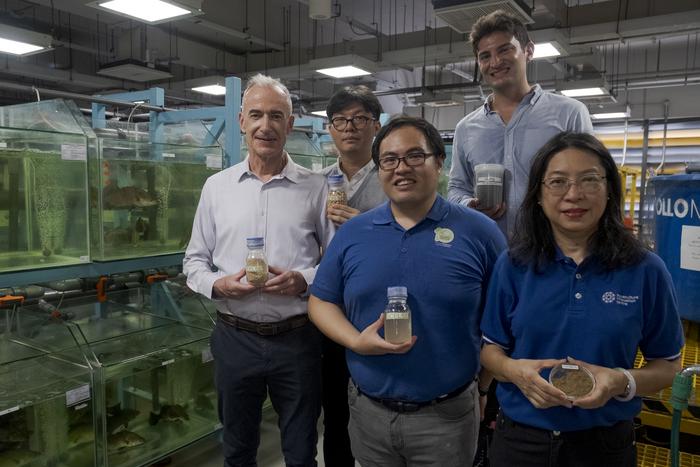

Credit: NTU Singapore

Scientists from Nanyang Technological University, Singapore (NTU Singapore) and Temasek Polytechnic have successfully replaced half of the fishmeal protein in the diets of farmed Asian seabass with a ‘single cell protein’ cultivated from microbes in soybean processing wastewater, paving the way for more sustainable fish farming practices.

The use of a cultivated protein is new to aquaculture production, say the scientists from the Singapore Centre for Environmental Life Sciences Engineering (SCELSE) leading NTU’s efforts in the study, and Temasek Polytechnic’s Aquaculture Innovation Centre (AIC).

Farmed aquaculture species rely heavily on feed made from wild-caught fish, known as fishmeal, which is not sustainable and contributes to overfishing of the seas.

Single cell protein, a sustainable alternative, can be cultivated from food processing wastewater. In particular, the wastewater from soybean processing contains organisms with probiotic potential that are essential for healthy fish growth.

Wastewaters from the food-processing industry are free of pathogens and other contaminants, make them suitable for growing microbes. Normally after processing the wastewater is discharged and flows into a wastewater reclamation plant. Its nutrients are not recovered, resulting in a lost opportunity to maximise resource use.

Co-lead author of the study, Dr Ezequiel Santillan, senior research fellow at SCELSE, said, “Our study represents a significant step forward in sustainable aquaculture practices. By harnessing microbial communities from soybean processing wastewater, we have demonstrated the feasibility of producing single cell protein as a viable alternative protein replacement in fish feed, reducing the reliance on fishmeal and contributing to the sustainability of the aquaculture industry.”

The joint research team said that their waste-to-resource approach tackles food security and waste reduction, supporting the development of a circular economy with zero waste as outlined in the United Nations Paris Agreement.

The study, published in the peer-reviewed science journal Scientific Reports, aligns with the University’s research pillar of NTU 2025, a five-year strategic plan that aims to leverage innovative research to mitigate human impact on the environment.

The study is also aligned with AIC’s focus on enhancing food security and resilience. With the aquaculture industry aiming to meet 30 per cent of Singapore’s total nutritional needs by 2030, AIC has been actively championing intensive aquaculture production with innovation and technology.

Replacing half of the usual fish feed for Asian seabass

To demonstrate their approach, the team added soybean processing wastewater from a food processing company in Singapore into bioreactors – a controlled environment for biological and chemical reactions – to cultivate single cell protein. The laboratory-scale bioreactors were operated in repeated cycles of controlled nutrient and low air supply (micro-aerobic conditions) for over four months at 30°C. These conditions suggest that the team’s method can be easily reproduced at ambient temperatures in tropical regions like Singapore, further reducing the environmental footprint of fishmeal production.

After producing their single cell protein, the research team fed two groups of young Asian seabass over 24 days. One group received a conventional fishmeal diet, while the other group was fed a diet of half regular fishmeal and half single cell protein. Both diets provided the same amount of nutritional content for the young fish.

At the end of the experiment, the growth of both groups was evaluated, and researchers found that the fish had grown the same amount. Interestingly, the group of fish on the new diet showed more consistent and less variable growth than the traditional diet group.

NTU Professor Stefan Wuertz at the School of Civil and Environmental Engineering and SCELSE’s Deputy Centre Director said, “The findings suggest that diets including single cell protein may help fish grow more uniformly, and exploring how this diet affects fish on a deeper level could be interesting for future research. More importantly, our study has successfully demonstrated the potential for converting soybean processing wastewater into a valuable resource for aquaculture feed, contributing to the transition to a circular bioeconomy.”

Co-principal investigator of the study, Dr Diana Chan, Head, Aquaculture Innovation Centre at Temasek Polytechnic said: “The results of our fish feeding performance trials are promising for the aquaculture industry, offering an alternative protein source to meet the increasing need to replace fishmeal which has become very costly and unsustainable in supply.”

For their next steps, the research team will conduct trials over longer growth periods with higher fishmeal replacement levels. Researchers will also expand the study to include additional aquaculture species and different types of food processing wastewater.

***END***

Journal

Scientific Reports

Method of Research

Experimental study

Subject of Research

Animals

Article Title

Microbial community-based protein from soybean-processing wastewater as a sustainable alternative fish feed ingredient

Article Publication Date

31-Jan-2024