In a groundbreaking development for the field of composite materials, researchers have unveiled a pioneering multiscale analysis of resin-rich regions within Carbon Fiber Reinforced Polymer (CFRP) composites. This innovative work, conducted by a team of experts led by Jing, Y., Zhao, H., and Yuan, M., integrates submodel techniques to provide unprecedented insights into the microscopic and macroscopic behaviors of CFRP composites. As industries increasingly rely on these materials for their lightweight and high-strength properties, understanding the nuanced behavior of their resin components becomes essential.

CFRP composites have revolutionized various industries, notably aerospace, automotive, and civil engineering, thanks to their superior mechanical properties. However, the challenges stemming from inhomogeneities, particularly in resin-rich regions, have long posed limitations on the predictive capabilities of mechanical performance. The researchers assert that a comprehensive understanding of these regions is critical for enhancing the durability and reliability of CFRP structures. With the advent of multiscale analysis, they dive deep into the intricate interactions occurring at different scales, which can significantly influence the performance of the entire composite material.

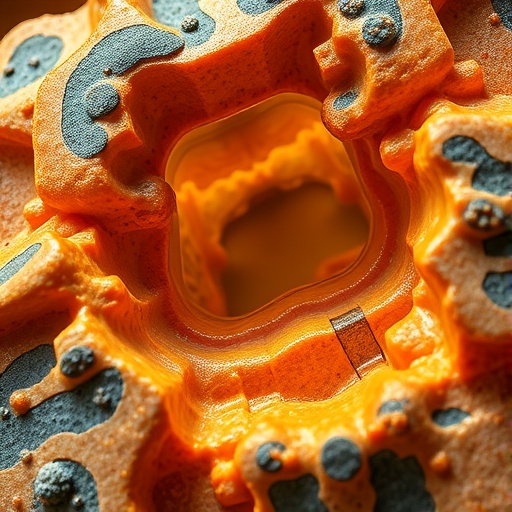

The study emphasizes the integration of submodel techniques that allow researchers to zoom into specific areas of interest within CFRP composites. By creating a detailed model of resin-rich regions, the team can analyze microstructural behaviors and their impact on macro-scale performance. This hierarchical approach is crucial, as it helps bridge the gap between empirical observations and theoretical predictions, yielding a more complete understanding of the material under stress.

One of the major focuses of the research is the assessment of failure mechanisms associated with resin-rich areas. The team employed advanced imaging techniques and computational methods to gather data on how these regions behave under various loading conditions. By simulating mechanical stresses, they were able to observe the initiation and propagation of micro-cracks, shedding light on the reasons behind premature failures in CFRP structures. These findings could lead to improved design practices that incorporate these insights into future composite material applications.

Moreover, the integration of multiscale analysis opens the door to predictive modeling of CFRP composite performance. With better understanding and modeling of resin-rich regions, manufacturers can optimize material compositions and fabrication processes, resulting in composites with extended life spans. This has significant implications for industries where weight savings are paramount without sacrificing safety and reliability, such as aerospace and automotive sectors.

The researchers also addressed the impact of environmental factors on resin-rich regions. Understanding how temperature, humidity, and exposure to chemicals influence the mechanical properties of these regions is key. Their findings suggest that resin composition and the curing process greatly affect bond strength and yield point. This insight emphasizes the necessity for stringent quality control during the manufacturing process of CFRP composites to ensure long-term reliability.

Furthermore, this analysis does not only pertain to CFRP composites; the methodologies developed in the study may have applications across various composite materials. The ability to effectively model and analyze resin-rich regions could lead to enhancements in the fiberglass, epoxy, and other composite material industries. This universality presents a unique opportunity for cross-industry collaboration aimed at improving reliability and longevity of composite materials.

In conclusion, the multiscale analysis of resin-rich regions in CFRP composites represents a significant advancement in materials science. By integrating submodel techniques, this research provides essential insights that could reshape manufacturing practices and material selection in several high-stakes applications. With their findings set to be published in the upcoming issue of “AS” in September 2025, the implications of this research promise to resonate throughout the industry for years to come.

Through this innovative study, researchers are not only addressing present challenges but also paving the way for future research and technological advancements within the realm of composite materials. As industries continue to embrace the capabilities of CFRP composites, the foundational knowledge gained from such studies will ensure that safety and efficiency remain at the forefront of material use in critical applications. The potential for improved predictive modeling is more than a hopeful outcome; it is an inevitable step toward the future of composite science.

The study underlines a crucial aspect of modern engineering—innovation driven by detailed scientific understanding. As the field continues to evolve, the integration of advanced analytical methods will be a cornerstone in unlocking the full potential of composite materials, leading to safer, more efficient, and more sustainable engineering solutions. With every advance in multiscale analysis methodologies, the dream of creating composites with unparalleled performance is inching closer to reality.

As the date for the public release of their findings approaches, the excitement in the materials science community is palpable. The anticipation stems not just from the results themselves, but from the broader implications these findings hold for the future of composite materials engineering. Researchers, engineers, and industry leaders alike are poised to leverage this knowledge, setting the stage for a new frontier in manufacturing excellence that prioritizes both performance and safety.

Subject of Research: Multiscale analysis of resin-rich regions in CFRP composites with submodel integration

Article Title: Multiscale analysis of resin-rich regions in CFRP composites with submodel integration

Article References:

Jing, Y., Zhao, H., Yuan, M. et al. Multiscale analysis of resin-rich regions in CFRP composites with submodel integration.

AS (2025). https://doi.org/10.1007/s42401-025-00372-y

Image Credits: AI Generated

DOI:

Keywords: CFRP composites, multiscale analysis, resin-rich regions, submodel integration, mechanical performance, failure mechanisms, materials science, predictive modeling.