Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have unveiled a groundbreaking innovation in robotic technology, unveiling the “field-programmable robotic folding sheet.” This pioneering development is set to transform how robots interact with their environments by enhancing their adaptability through real-time programmable features. The key to this innovation lies in its ability to change shape on command, a significant breakthrough for robotic design that promises to push the boundaries of engineering and automation.

Folding structures have long been a staple in robotic design, celebrated for their efficiency in shape-morphing and utility in various applications ranging from aerospace and space exploration to soft robotics and foldable grippers. However, conventional folding mechanisms have limitations; they rely on fixed hinges and predetermined folding directions. This rigidity necessitates costly and time-consuming redesign every time the operating environment or robotic task shifts. Acknowledging these limitations, the KAIST research team set out to develop a more flexible, programmable solution.

The accomplished researchers—Professors Inkyu Park and Jung Kim, along with their colleagues—have successfully implemented the concept of “field-programmability” into foldable structures. This technology integrates innovative material science with advanced programming methodologies, allowing users to determine specific parameters such as folding direction and intensity. Remarkably, all this can be executed in real time. Thus, this technology revolutionizes how robots can adapt to diverse tasks and changes, offering unprecedented functionalities with minimal disruptions.

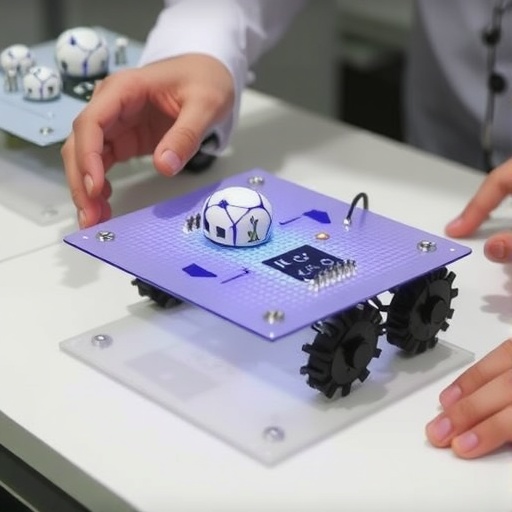

At the core of this robotic sheet is a thin, flexible polymer substrate embedded with a sophisticated network of micro metal resistors. These unique resistors serve dual purposes; they function as both heaters and temperature sensors. This integration allows the robotic sheet to independently manage its folding states without the need for external control devices. This self-sufficient capability enhances operational efficiency while simplifying the control mechanics of the robotic sheet.

What makes this programmable sheet even more innovative is its accompanying software, which combines powerful genetic algorithms and cutting-edge deep neural networks. This sophisticated software enables users to input parameters for folding—while also estimating the precise control needed for heating and cooling to achieve the desired shape. The sheet autonomously manages these heating and cooling cycles, demonstrating remarkable precision in real-time fold adjustments.

The unique closed-loop control mechanism at play in this system ensures that the temperature distribution across the sheet is optimally regulated. Such control enhances both the precision of real-time folds and the responsiveness of the fabric to environmental fluctuations. It also addresses the often-detrimental slow response times associated with traditional heat-based folding technologies. This responsiveness is critical to the practical functions that these robotic sheets can perform, making them advantageous for a myriad of applications, particularly in dynamic environments.

The newfound capability for real-time shape programming allows for a wide array of robotic applications to be executed instantaneously, erasing the need for cumbersome hardware redesign processes. For instance, the research team successfully created an adaptive robotic hand capable of customizing its grasping methodologies to suit various object geometries using a single material. This adaptability significantly streamlines operational versatility and extends the utility of the robotic technology in various scenarios.

In another demonstration of the sheet’s capabilities, researchers placed the robotic structure on the ground, enabling it to autonomously walk and crawl, thus mimicking bio-inspired locomotion patterns. This showcases a possibility for the development of environmentally adaptive and autonomous robots that can change their forms in response to external stimuli—a concept that could have far-reaching implications in numerous fields such as search and rescue, surveillance, and exploration.

As a testament to the study’s significance, Professor Jung Kim remarked that this research strides towards realizing “morphological intelligence.” This concept posits that the very shape of an object can embody intelligence, facilitating autonomous motion based on context. The researchers envision practical applications of this technology within disaster-response robotics, bespoke medical assistive devices, and tools for space exploration. With efforts focused on enhancing material properties for increased load-bearing capacity and expedited cooling times, the team aims to create electrode-free, fully integrated designs that extend this technology across various forms and sizes.

The insights gained from this work could signal a paradigm shift in how we approach robotic design and functionality, as it aligns closely with the evolving concept of robots that can learn, adapt, and respond intelligently to their environments. The full potential of this innovation, which was co-led by Dr. Hyunkyu Park and Professor Yongrok Jeong and was recently published in the August 2025 edition of the prestigious journal Nature Communications, is just beginning to be realized. As research continues, the implications of a programmable folding robotic sheet could redefine what is possible in automation and robotics.

By integrating advanced materials, smart programming, and robust sensing technologies, the KAIST team has set the stage for a new era in robotics, where adaptability and intelligence are inherently built into the fabric of robotic systems. As this research continues to develop, it opens the door to innovative applications that can fundamentally change industries and improve efficiency in diverse fields ranging from healthcare to space exploration.

Researchers anticipate that further advancements will lead to even richer capabilities and enhance the utility of these robotic systems, paving the way for implementations that were once considered purely speculative. This journey into programmable robotics not only signifies technical progress but also heralds a future where robots can efficiently address real-world challenges through intelligent design.

In conclusion, the KAIST development of the field-programmable robotic folding sheet ushers in a new dimension of adaptability and intelligence in robotics. It stands as a bold statement of what can be achieved when innovation meets practical engineering, and it invites researchers, engineers, and industry professionals to imagine the limitless opportunities that lie ahead in the realm of programmable robotics.

Subject of Research:

Article Title: Field-Programmable Robotic Folding Sheet: Shaping the Future of Robotics

News Publication Date: August 2025

Web References:

References:

Image Credits: KAIST

Keywords

Field-programmable robotics, shape-morphing mechanisms, adaptive design, intelligent automation, robotic systems.