In recent years, the quest for highly efficient and durable catalysts for propane dehydrogenation—a critical process for propylene production—has intensified due to the growing demand for sustainable and cost-effective chemical transformations. Propylene serves as a fundamental building block in the petrochemical industry, and advances in catalyst design can significantly enhance industrial productivity and environmental benefits. In this context, researchers led by Prof. Jihong Yu at Jilin University have made a remarkable breakthrough with the development of a novel zeolite-encapsulated platinum-copper (PtCu) alloy catalyst. This innovative catalyst combines cost-effectiveness, high activity, and excellent stability, promising transformative impacts on propane dehydrogenation technology.

The team adopted a unique post-synthesis modification strategy that diverges from conventional ligand-assisted encapsulation techniques often used in the preparation of metal-zeolite catalysts. Traditional methods typically involve organic ligands to stabilize metal precursors during hydrothermal synthesis; however, these approaches suffer from significant drawbacks, including high production costs and diminished metal utilization efficiency, which hinder industrial scalability. To circumvent these limitations, Prof. Yu’s group engineered a method leveraging ion exchange followed by a metal replacement reaction, using commercially available ZSM-5 zeolite as the support framework. This approach not only simplifies the synthesis process but also ensures the encapsulation of well-dispersed, ultrasmall alloy nanoparticles within the zeolite micropores.

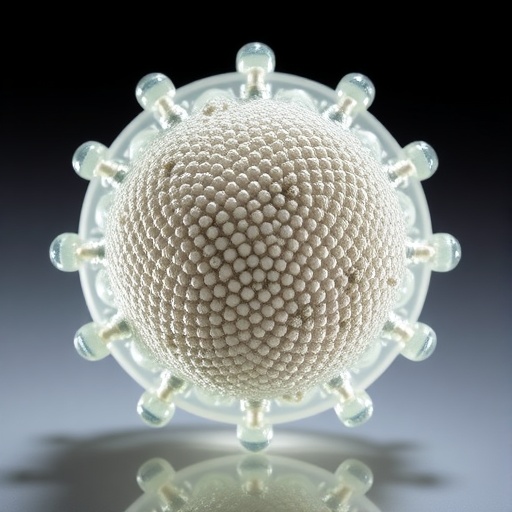

The synthetic route initiates by introducing Cu²⁺ ions into the zeolite framework through ion exchange, exploiting the zeolite’s inherent microporous architecture and ion-exchange capacity. Subsequent high-temperature reduction transforms the copper ions into metallic copper confined inside the zeolite channels, forming an intermediate Cu@MFI material. This intermediate serves a dual function: it acts as both a structural template and a sacrificial template for the subsequent incorporation of platinum. The critical step involves a controlled metal replacement reaction where platinum precursors, specifically Pt(NH₃)₄₂, displace copper atoms within the zeolite pores. This displacement leads to the in situ formation of a PtCu alloy encapsulated with exceptional uniformity in the zeolite matrix, referred to as PtCu@MFI.

Notably, the ability to fine-tune the Pt/Cu atomic ratio via adjustment of variables such as the silicon-to-aluminum (Si/Al) ratio and metal loading within the zeolite is a hallmark of this method’s versatility. Among various tested compositions, PtCu₅@MFI-K (a molar ratio of platinum to copper of 1:5) showcased remarkable catalytic efficacy under stringent reaction conditions. At a reaction temperature of 550 °C and a moderate weight hourly space velocity (WHSV) of 3.6 h⁻¹, this catalyst achieved a propane conversion rate nearing 50%, with propylene selectivity surpassing 90%. Even at an elevated WHSV of 108 h⁻¹, the catalyst maintained an initial propane conversion of 41% and an exceptional propylene selectivity of 97.7%, underscoring its robustness and efficiency.

The catalytic prowess of PtCu₅@MFI-K is attributed largely to the synergistic effects arising from the PtCu alloying and the spatial confinement provided by the MFI zeolite structure. The alloying with copper not only enhances the dispersion of active platinum sites but also remarkably improves resistance to sintering and deactivation processes that plague many noble metal catalysts under high-temperature operating conditions. The zeolite matrix offers a protective nanoreactor environment, restricting nanoparticle agglomeration and facilitating selective catalytic pathways, thereby ensuring sustained activity and selectivity over multiple reaction cycles.

This innovative synthesis strategy also marks a pivotal departure from reliance on organic-ligand protection, prevalent in current alloy@zeolite catalyst production methods. Avoiding organic ligands reduces the environmental impact and manufacturing cost while enhancing metal atom economy. The post-treatment approach demonstrated by Prof. Yu and her colleagues is eminently scalable and compatible with industrial manufacturing requirements, bridging a critical gap between fundamental research and practical catalytic applications.

From a mechanistic standpoint, the metal replacement reaction exploits the relative electrochemical potentials of copper and platinum, allowing platinum ions to displace copper atoms within the zeolite pore structure under reductive atmospheres. This dynamic process enables atomic-level mixing and alloying, which is challenging to achieve via direct co-impregnation or physical mixing methods. The selective replacement not only ensures a homogeneous alloy composition but also preserves the microporous zeolite integrity, which is crucial for sustained molecular-level confinement and catalyst durability.

The catalytic system’s capacity to maintain high propylene selectivity, especially at high conversion rates and reaction rates, is a significant industrial advantage. Propylene is an essential precursor for producing polymers, solvents, and various chemicals, and minimizing undesired side reactions such as cracking or coke formation is critical for process efficiency and lowering operational downtime. The demonstrated cyclic stability of the PtCu₅@MFI-K catalyst over multiple dehydrogenation/regeneration cycles reinforces its suitability for long-term industrial deployment.

This research, published as an open-access article in CCS Chemistry—an influential journal under the aegis of the Chinese Chemical Society—highlights the synergistic integration of fundamental catalysis principles with pragmatic synthesis methodologies. The study exemplifies how ion exchange combined with displacement reactions can be leveraged to construct sophisticated alloy nanostructures confined within zeolite frameworks, opening new avenues for catalyst design beyond propane dehydrogenation, potentially extending to other hydrocarbon transformations and environmental catalysis.

The successful encapsulation of PtCu alloys within ZSM-5 zeolites sets a benchmark for future exploration of multi-metallic catalysts with tunable compositions and architectures. Researchers can adapt this metal replacement strategy to various zeolite types and alloy systems, tailoring catalysts for precision control of activity, selectivity, and stability across a broad spectrum of chemical reactions. Additionally, the methodology offers intriguing opportunities to explore cooperative effects between metal components and zeolite acidity, thereby optimizing catalysts for complex reaction networks.

Further research will undoubtedly focus on elucidating the atomic-scale interactions between platinum, copper, and the zeolite framework. Advanced characterization techniques such as aberration-corrected electron microscopy, in situ spectroscopy, and computational modeling will be instrumental in uncovering the mechanistic underpinnings that govern catalyst performance and durability. Such insights will guide the rational design of next-generation alloy catalysts, with heightened resistance to deactivation phenomena like sintering, coking, and metal leaching.

The implications of this work transcend catalysis for propylene production. It represents a strategic advancement in sustainable catalyst manufacturing, emphasizing cost reduction, resource efficiency, and scalability without compromising performance. Given the global push towards greener chemical processes and the need for robust catalysts capable of operating under harsh industrial conditions, the approach pioneered by Prof. Yu’s team stands as a paradigm for developing environmentally friendly and economically viable catalytic technologies.

In conclusion, the combination of ion exchange and metal replacement to fabricate zeolite-confined PtCu alloy catalysts is a landmark achievement that addresses longstanding challenges in heterogeneous catalysis. The impressive catalytic activities, durability, and selective hydrocarbon transformations demonstrated in propane dehydrogenation affirm the broader potential of this methodology. This breakthrough not only enriches the catalyst design toolbox but also accelerates the transition towards efficient and sustainable chemical processes vital for the petrochemical industry and beyond.

Subject of Research: Not applicable

Article Title: Zeolite-Encapsulated PtCu Alloy Catalysts Enabled by Metal Replacement for Propane Dehydrogenation

News Publication Date: September 17, 2025

Web References: https://www.chinesechemsoc.org/journal/ccschem

References: DOI: 10.31635/ccschem.025.202506177

Image Credits: CCS Chemistry

Keywords

Heterogeneous catalysis