In the rapidly evolving landscape of additive manufacturing, a groundbreaking advancement from MIT promises to revolutionize the traditional 3D printing workflow by introducing a resin capable of forming both robust structures and easily dissolvable supports in a single print. This innovation addresses a longstanding challenge in vat photopolymerization — the manual removal and disposal of structural supports, which has historically hindered speed, efficiency, and sustainability in producing intricate, customized objects.

Vat photopolymerization, a widely adopted 3D printing technique, relies on sequential exposure of photosensitive resin to patterned light. UV light solidifies the resin layer by layer into precise geometries, but to maintain dimensional stability during printing, temporary support scaffolds must be integrated. These supporting structures, printed from the same material as the functional parts, require time-consuming, delicate manual post-processing to remove, often resulting in material waste. MIT engineers have now engineered a resin system that selectively cures into two drastically different polymer networks depending on the light wavelength applied—enabling the fabrication of both resilient components and sacrificial supports within the same printing session.

The resin exhibits a remarkable dual-phase behavior. When irradiated with ultraviolet (UV) light, it cures into a tightly cross-linked, mechanically strong solid that endures subsequent chemical exposure. Conversely, exposure to visible light triggers polymerization pathways that yield a loosely interconnected network prone to rapid dissolution in benign solvents. Leveraging this property, the MIT team devised a printing strategy involving simultaneous projecting of UV and visible light patterns: UV light constructs the actual product, while visible light builds the underlying and surrounding supports, which dissolve with ease post-printing.

This discovery eliminates the arduous, manual detachment of support scaffolds. Instead, once the print completes, the entire object is immersed in a solvent bath that gently removes the visible-light-cured supports, revealing the intricate, UV-hardened parts. Intriguingly, the supports dissolve in several non-toxic, food-safe liquids, including commonplace substances like baby oil or even in the monomeric resin base itself, akin to how ice melts harmlessly in water. This trait opens the door to unprecedented recyclability—dissolved support material blends back into fresh resin, enabling closed-loop reuse and drastically diminishing waste generation within the additive manufacturing workflow.

Development of this twofold resin system demanded meticulous chemical engineering. Initially, the researchers mixed two commercially available monomers known to polymerize into different network architectures depending on activating light. However, initial formulations yielded UV-cured parts that disintegrated when submerged in solvents, revealing incomplete cross-linking under the printer’s LED intensities compared to benchtop tests. By introducing a third, bridging monomer, they succeeded in reinforcing the UV-cured matrix, knitting polymer chains into a stable, insoluble scaffold, while preserving the visible-light-sensitive, solubilizable phase for supports.

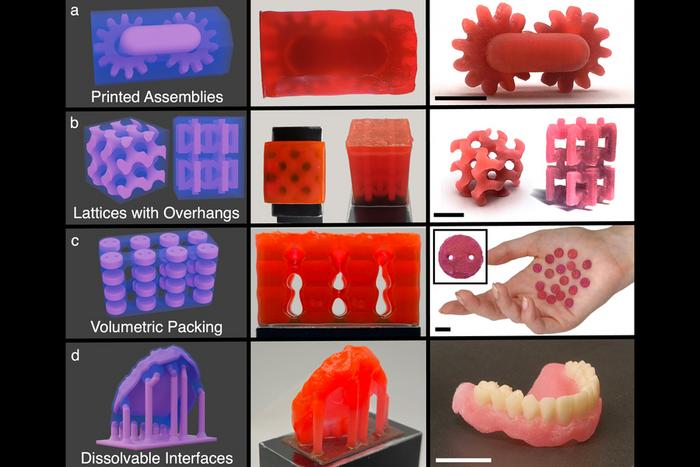

With this optimized resin, MIT researchers printed a variety of complex forms that traditionally challenge support removal, such as multipart gear trains with interlocking elements, elaborate lattice frameworks, and even a playful dinosaur model ensconced in an egg-shaped lattice that dissolved away post-print. The technology demonstrates potential for applications demanding personalized, intricate parts, including hearing aids, dental implants, and mouth guards—domains where augmenting production speed and reducing waste translates to tangible benefits for manufacturers and consumers alike.

Beyond simplifying post-processing, this dual-wavelength vat photopolymerization technique fundamentally expands the design freedom of the 3D printing process. Multi-material assemblies with precise, moving interfaces can be printed in one continuous run without risking damage during manual support removal. Welding these advances with automation and solvent recycling promises a sustainable paradigm shift in polymer 3D manufacturing, combining resource efficiency, reduced production costs, and a smaller environmental footprint.

Currently, the research team explores extending this wavelength-selective curing concept to resins with diverse mechanical properties tailored for varying functional requirements. They aim to enhance scale-up strategies including robotic handling systems and closed-loop feedback control integrating dissolved resin recovery for industrial applicability. By integrating such innovations, polymer vat photopolymerization could soon achieve new levels of throughput and precision, ushering in a new era of on-demand fabrication with less waste and greater material circularity.

Professor A. John Hart, lead investigator and head of MIT’s Department of Mechanical Engineering, emphasizes the transformative potential of this technology: “Our approach addresses a fundamental bottleneck in photopolymerization 3D printing. By enabling precise spatial control over resin properties via light wavelength, we pioneer a platform that not only accelerates production but also promotes sustainability.” Graduate student Nicholas Diaco adds, “The ability to wash away supports with simple, environmentally friendly solvents and then recycle them onsite significantly reduces material waste and operational complexity.”

This innovative method, detailed in a recent publication in Advanced Materials Technologies, garnered support from prominent funding agencies including the U.S. National Science Foundation and the U.S. Army Research Office, reflecting its important implications for defense manufacturing and broader industrial use. The compelling synergy of chemistry, photonics, and mechanical engineering showcased here exemplifies the interdisciplinary progress driving additive manufacturing frontiers today.

In summation, MIT’s dual-wavelength vat photopolymerization method heralds a paradigm shift for 3D printing: a revolutionary technique that integrates the fabrication of durable parts and dissolvable supports in a single, streamlined printing step. By alleviating manual post-processing, enabling solvent-based support removal, and fostering resin recyclability, this innovation promises widespread impact—from personalized healthcare devices to sustainable industrial production—positioning itself as a pivotal advancement in the journey toward greener, faster, and more versatile additive manufacturing.

Subject of Research: Dual-wavelength vat photopolymerization enabling dissolvable, recyclable supports for advanced 3D printing

Article Title: “Dual-Wavelength Vat Photopolymerization with Dissolvable, Recyclable Support Structures”

Web References:

DOI: 10.1002/admt.202500650

References:

Nicholas Diaco, Carl Thrasher, Max Hughes, Kevin Zhou, Michael Durso, Saechow Yap, Robert Macfarlane, and A. John Hart. “Dual-Wavelength Vat Photopolymerization with Dissolvable, Recyclable Support Structures.” Advanced Materials Technologies.

Image Credits: Courtesy of Nicholas Diaco, Carl Thrasher, Max Hughes, Kevin Zhou, Michael Durso, Saechow Yap, Robert Macfarlane, and A. John Hart

Keywords: Additive manufacturing, vat photopolymerization, dual-wavelength resin, dissolvable supports, recyclable 3D printing materials, polymer chemistry, functional assemblies, sustainable manufacturing, materials engineering, mechanical engineering, polymer 3D printing