In a groundbreaking study published in the journal Environmental Science and Pollution Research, researchers Bouazizi, Morshed, and Nierstrasz have unveiled a novel approach that leverages the unique properties of chitosan for the in situ self-assembly of copper (Cu) and nickel (Ni) nanoparticles. This innovative methodology holds significant promise for applications in catalysis, potentially transforming the efficiency of various chemical reactions. By harnessing chitosan, a biopolymer derived from chitin, this research paves the way for more sustainable and environmentally friendly catalytic processes.

The researchers embarked on their investigation recognizing the critical role that metal nanoparticles play in catalytic applications. The high surface area and unique electronic properties of nanoparticles make them ideal candidates for enhancing reaction rates. Copper and nickel, in particular, have garnered interest due to their abundance and cost-effectiveness, making them suitable alternatives to precious metals like palladium and platinum. However, aggregating these nanoparticles into stable and effective configurations has always posed a challenge.

The team identified chitosan as a potential solution. Chitosan, known for its biocompatibility and non-toxicity, possesses inherent abilities to interact with metal ions. This study explored how chitosan could provide a framework for the self-assembly of copper and nickel nanoparticles, allowing for more controlled positioning and stabilization, ultimately improving catalytic performance. The findings suggest that the chitosan framework not only stabilizes the metallic clusters but also enhances their accessibility to reactants, making the catalytic process more efficient.

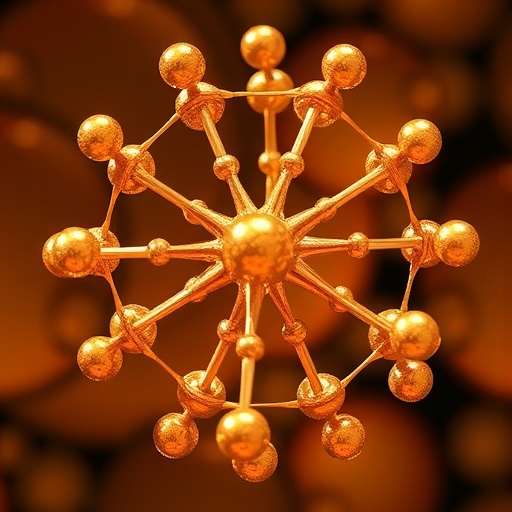

Utilizing a combination of wet chemistry techniques, the researchers synthesized Cu and Ni nanoparticles within a chitosan matrix. By adjusting the concentration of the precursor solutions and the chitosan, they could manipulate the size and distribution of the nanoparticles across the substrate. Characterization techniques such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were employed to thoroughly investigate the morphology of the self-assembled structures. The images revealed well-dispersed nanoparticles embedded within the chitosan fibers, confirming the successful assembly of the dual-metal catalyst.

One of the most impressive aspects of this work is the evaluation of the catalytic activity of the newly developed materials. The team carried out several catalytic tests using model reactions to assess the performance of the Cu/Ni nanoparticles compared to traditional catalysts. The results were striking, showing that the chitosan-stabilized nanoparticles exhibited significantly enhanced catalytic activity. This improvement can be attributed to the increased surface area available for reactants to interact and the facilitated electron transport pathways provided by the chitosan.

Moreover, the environmental implications of this research cannot be overstated. Traditional methods of synthesizing high-performance catalysts often involve toxic reagents and conditions that pose risks to both human health and the environment. In contrast, this approach utilizing chitosan not only minimizes the use of hazardous materials but also offers a biodegradable alternative, aligning with the principles of green chemistry. This could represent a significant step forward in developing sustainable catalytic processes.

The flexibility of the chitosan framework enables further exploration into other metal combinations and possibly other polymeric materials, opening doors to a myriad of applications in catalytic processes. Future research could pivot towards optimizing the synthesis parameters even further to enhance the catalytic efficiency and lifespan of these nanoparticles. There are also intriguing opportunities to explore the functionalities of the chitosan matrix itself, potentially incorporating other catalysts or enhancing its properties for specific industrial applications.

Another aspect worthy of mention is the economic viability of this technology. Given the global push toward more sustainable practices, the ability to produce effective catalysts from abundant, low-cost materials like copper and nickel while utilizing a renewable biopolymer makes this method attractive for manufacturing industries. This could lead to more affordable catalytic processes that not only reduce operational costs but also lower the environmental footprint associated with traditional methods.

In addition to industrial applications, the implications of this research may extend into pharmaceuticals where catalysis plays a significant role in synthesizing active pharmaceutical ingredients. The versatility and efficacy of chitosan-stabilized metal nanoparticles could revolutionize synthetic pathways for complex molecules, ultimately contributing to more efficient drug development processes.

The researchers’ considerations extend beyond the laboratory. There is an awareness and commitment to ensuring that the benefits discovered through this research translate into practical applications that can be applied in real-world scenarios. Engagement with industrial partners and stakeholders will be essential in ensuring that the technology is brought to market, providing significant environmental and economic benefits.

All in all, this study contributes to a growing body of literature exploring biopolymer-mediated synthesis of metal nanoparticles, representing not just an incremental advance but a potential paradigm shift in the area of catalysis. As industries increasingly seek green alternatives, the integration of chitosan-based solutions may serve as a benchmark for future research and development in this field. It remains to be seen how rapidly this research will translate into widespread applications, but the momentum generated by such findings suggests an exciting frontier ahead in sustainable catalysis.

In conclusion, the innovative use of chitosan to self-assemble copper and nickel nanoparticles marks a significant advancement in catalysis research. With improved catalytic activity, environmental benefits, and commercial viability, this work by Bouazizi and colleagues is set to inspire further exploration into sustainable materials and processes. These findings challenge the conventional paradigms of catalyst development and align with the global imperative for greener chemistry, thus demonstrating the critical intersection of material science and environmental stewardship.

Subject of Research: Catalytic activity of chitosan-stabilized copper and nickel nanoparticles

Article Title: Chitosan for new in situ self-assembly way to arrange Cu and Ni nanoparticles: useful configuration with high catalytic activity.

Article References:

Bouazizi, N., Morshed, M.N., Nierstrasz, V. et al. Chitosan for new in situ self-assembly way to arrange Cu and Ni nanoparticles: useful configuration with high catalytic activity.

Environ Sci Pollut Res (2025). https://doi.org/10.1007/s11356-025-36833-2

Image Credits: AI Generated

DOI: 10.1007/s11356-025-36833-2

Keywords: chitosan, copper nanoparticles, nickel nanoparticles, catalysis, self-assembly, green chemistry