In a groundbreaking study poised to revolutionize material science and surface engineering, researchers have unveiled a novel technique that combines electropulsing with laser shock imprinting to fabricate hierarchical and bio-inspired surfaces directly on bulk metals. This innovative process not only enhances the mechanical properties of metals but also imparts sophisticated surface features previously thought possible only by complex and multi-step fabrication methods. The method’s implications stretch across numerous industries, including aerospace, biomedical implants, and advanced manufacturing, marking a significant leap forward in precision surface modification technologies.

Traditional surface texturing methods often rely on chemical etching, lithography, or laser patterning techniques that pose limitations in terms of resolution, scalability, and the ability to preserve underlying bulk properties of metals. The new approach, referred to as electropulsing-assisted laser shock imprinting (E-LSI), ingeniously fuses the high strain-rate plastic deformation induced by laser shock waves with the enhanced material softening effects generated by controlled electropulses. This combination enables precise imprinting of complex hierarchical designs, mimicking naturally occurring biomimetic structures, such as lotus leaves, shark skin, or butterfly wings—surfaces renowned for their superior hydrophobicity, friction reduction, and light manipulation.

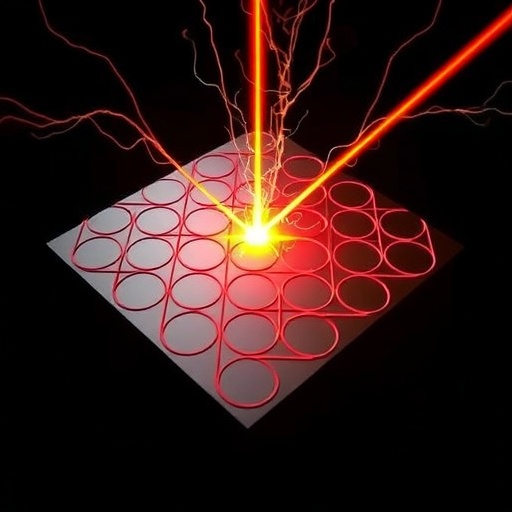

At the heart of E-LSI lies the synchronization of ultra-short and intense laser pulses that generate shock waves capable of plastically deforming metal surfaces with electropulses applied simultaneously or in sequence to promote localized and transient reductions in metal strength. Electropulsing, as a physical phenomenon, temporarily alters dislocation mobility and activates thermally assisted plasticity without damaging the metal microstructure irreversibly. This synergistic effect permits the imprinting process to occur at lower pressures while achieving deeper and more intricate surface features than conventional laser shock alone.

The hierarchical nature of the engraved surfaces is critical. By manipulating the resonance between the laser shock wave parameters and the electropulsing regime, the research team successfully fabricated surfaces featuring multi-scale roughness ranging from the nanoscale to the microscale. These layered architectures emulate natural surfaces that provide exceptional functionalities such as self-cleaning, anti-biofouling, and directional wettability. The possibility of generating such complex textures on bulk metals paves the way for designing next-generation materials with tailor-made surface properties built intrinsically into the substrate.

One of the remarkable advantages of the E-LSI method is its capacity to directly form textures on bulk metals without necessitating coating or layering. This aspect not only simplifies the manufacturing workflow but also improves functional durability since the imprinted structures become integral to the metal, resisting delamination, wear, and chemical degradation that often plague applied coatings or additive textures. The approach is compatible with a variety of metals including titanium, stainless steel, and aluminum alloys, showcasing its versatility across materials widely used in biomedical devices, automotive components, and aerospace structures.

In experimental validations, titanium samples treated with E-LSI demonstrated markedly enhanced hydrophobicity, with contact angle measurements indicating superior water repellency relative to untreated counterparts. Microscopic analysis revealed the pristine formation of micro-ridges and nanoprotrusions that contribute to water droplet repulsion, mimicking characteristics seen in lotus leaf surfaces. Simultaneously, mechanical testing underscored the preservation of bulk strength and fatigue resistance, highlighting that the electropulsing component successfully mitigates the typical embrittlement associated with laser-based surface modification techniques.

Beyond hydrophobicity, the bio-inspired textures impart anti-reflective properties that hold promising applications in optics and photovoltaics. By adjusting the laser and electropulsing parameters, surfaces were tailored to reduce light glare and enhance absorption across visible and near-infrared spectra. This tunability was exploited to demonstrate prototype metal surfaces potentially suitable for next-generation solar cell substrates, where maximizing light capture remains a pivotal challenge. The integration of surface engineering with bulk metal functionality reduces complexity and weight, critical factors in sustainable and efficient energy solutions.

Electropulsing-assisted laser shock imprinting also introduces an environmentally friendly alternative to traditional chemical surface treatments, eliminating the need for harmful acids, solvents, or multi-step coatings. The process uses clean physical principles, harnessing electromagnetic energy and precise laser input, providing a green manufacturing path that aligns with increasing industry emphasis on sustainability and waste reduction. The capability to rapidly produce complex patterns with minimal post-processing further underscores its industrial scalability and economic feasibility.

Future extensions of this technology may venture into adaptive surface design, where electropulses and laser shocks are dynamically controlled through feedback systems to generate surfaces optimized for real-time environmental interactions. This would open possibilities for “smart metals” with surfaces that respond to humidity, temperature, or mechanical stimuli by changing their wettability, friction, or reflectiveness. Such advancements could transform fields ranging from microfluidics and wearable devices to aerospace protection systems.

The interdisciplinary research team behind this discovery combines expertise in laser physics, materials science, surface chemistry, and mechanical engineering, underscoring the collaborative nature required to innovate at the intersection of diverse scientific domains. Their findings, detailed in the latest issue of npj Advanced Manufacturing, provide a comprehensive blueprint for harnessing combined physical effects to augment material functionality beyond classical limits.

In conclusion, the introduction of electropulsing-assisted laser shock imprinting represents a paradigmatic shift in surface engineering, enabling hierarchical, bio-inspired surfaces directly on bulk metals with unprecedented precision, efficiency, and scalability. This transformative approach opens a new horizon in functional material design, promising to catalyze revolutionary applications in industries where surface interactions dictate performance, lifespan, and environmental compatibility. As this technology progresses from laboratory demonstration to industrial adoption, it has the potential to redefine manufacturing standards and empower the creation of materials that truly reflect nature-inspired sophistication.

Subject of Research: Surface engineering of bulk metals using combined electropulsing and laser shock imprinting techniques

Article Title: Electropulsing-assisted laser shock imprinting for hierarchical and bio-inspired surface on bulk metal

Article References:

Liu, X., Wang, Y., Jiang, H. et al. Electropulsing-assisted laser shock imprinting for hierarchical and bio-inspired surface on bulk metal. npj Adv. Manuf. 2, 44 (2025). https://doi.org/10.1038/s44334-025-00053-w

Image Credits: AI Generated