In the relentless global quest to combat climate change, researchers are innovating technologies aimed not just at reducing carbon dioxide emissions but also at capturing and transforming this greenhouse gas into valuable products. A promising breakthrough has emerged from a multinational team of scientists who have developed a novel approach utilizing distributor-type membrane reactors to enhance the methanation of carbon dioxide. This technology shows remarkable potential in advancing carbon capture and utilization, marking a significant leap toward sustainable energy solutions.

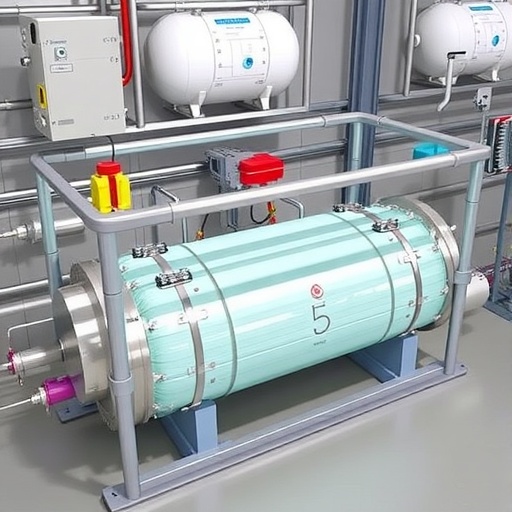

At the core of this pioneering research, led by Professor Mikihiro Nomura of the Shibaura Institute of Technology (SIT), lies the concept of spatially controlled methanation reactions within membrane reactors. These reactors allow for distributed reactant feeding, effectively mitigating hotspots that typically diminish catalyst performance and reactor efficiency. By managing reaction rates and thermal profiles with precision, this approach transcends traditional reactor designs and opens new avenues for energy-efficient chemical conversions.

Despite the theoretical advantages, the impact of specific membrane properties and the associated heat transfer characteristics within these reactors had not been thoroughly understood prior to this study. Addressing this knowledge gap, the collaborative research team embarked on a detailed investigation focusing on the thermal and material parameters influencing the reactor’s performance. Their findings promise to refine reactor design principles and enhance the overall conversion efficiency of carbon dioxide to methane.

Utilizing an advanced porous alumina (Al₂O₃) membrane, the researchers conducted precise laser flash analysis to characterize its thermal conductivity. This assessment revealed that the solid phase of the porous alumina membrane exhibits thermal conductivity reduced by approximately 36.4% compared to non-porous alumina. Such reduced conductivity is significant, affecting heat dissipation and temperature uniformity inside the reactor, which are critical for maintaining catalyst activity and stability during exothermic methanation reactions.

Further advancing the reactor design, the team integrated a catalytic membrane comprising a silica separation layer. This membrane demonstrated impressive hydrogen permeability, with a gas permeance of 1.4 × 10⁻⁶ mol m⁻² s⁻¹ Pa⁻¹, coupled with a remarkable hydrogen-to-carbon dioxide selectivity ratio of 35.9. Under test conditions at 350 °C, these properties facilitated a high carbon dioxide conversion efficiency of 92.3%, underscoring the synergy between membrane material characteristics and catalytic performance.

Complementing experimental work, the researchers employed computational fluid dynamics simulations using Ansys Fluent software to dissect the influence of membrane thermal conductivity and gas permselectivity on reactor behavior. Simulation outcomes indicated that membranes selectively permeable to carbon dioxide—with a permselectivity of 35.9—enhance methane production by a factor of approximately 1.4 times compared to membranes favoring hydrogen permeation, which exhibited significantly lower selectivity near 0.10. These insights validate the strategic importance of membrane selectivity in optimizing reactor output.

Thermal conductivity, a crucial parameter in this system, also played a key role in modulating the internal temperature gradients of the reactor. Increased thermal conductivity within the membrane matrix effectively suppresses excessive temperature rises, contributing to the stabilization of reaction environments and preventing catalyst deactivation. This thermal management capability establishes distributor-type membrane reactors as uniquely adaptable for the variable conditions inherent in small-scale industrial applications.

The ability of membrane reactors to facilitate both axial and radial control over reaction conditions via spatially distributed feed streams has broad implications. This distinctive operational flexibility makes them exceptionally well-suited for decentralized deployment, especially in small- to medium-sized enterprise settings where localized carbon dioxide sources prevail, but capital investment for large-scale infrastructure is prohibitive. Such adaptability aligns closely with emerging global efforts aimed at carbon neutrality through scalable, modular technology.

Professor Nomura emphasizes the transformative potential of this technology for smaller combustion devices, including boilers, which are often overlooked in climate mitigation strategies. The distributed reactant feeding inherent in distributor-type membrane reactors could substantially reduce carbon footprints in myriad industrial processes by enabling on-site carbon dioxide conversion. This could dramatically shift the landscape of sustainable energy applications, particularly in sectors where emissions control has remained challenging.

The environmental benefits of this work extend beyond carbon dioxide methanation. The fundamental insights into membrane material performance, heat transfer, and catalytic integration provide a blueprint for optimizing other exothermic reactions, such as hydrocarbon partial oxidation. By advancing membrane reactor technologies broadly, this research contributes to the acceleration of sustainable chemical processes vital for meeting future energy demands responsibly.

This collaborative research, published in the esteemed journal Catalysis Today, not only bridges experimental and computational methods but also exemplifies international scholarly cooperation between Japan’s Shibaura Institute of Technology and Poland’s AGH University of Krakow. The multidisciplinary approach underscores the growing importance of global partnerships in tackling complex environmental challenges through science and engineering ingenuity.

In conclusion, distributor-type membrane reactors represent a sophisticated technology platform with the transformative potential to revolutionize carbon dioxide utilization. By tailoring membrane properties and controlling heat and mass transfer at unprecedented levels, scientists are setting the stage for a new era of efficient, small-scale, and economically viable carbon-neutral energy systems. This breakthrough is a beacon of hope in the global effort to mitigate climate change and transition towards a sustainable future.

Subject of Research: Carbon dioxide methanation reaction in distributor-type membrane reactors and the effect of membrane properties on reaction efficiency.

Article Title: Effect of membrane properties on CO2 methanation reaction by using distributor type membrane reactor

News Publication Date: 1-February-2026

Web References:

https://doi.org/10.1016/j.cattod.2025.115569

References:

Nomura, M., Shimizu, Y., Moździerz, M., Brus, G., & Fornalik-Wajs, E. (2026). Effect of membrane properties on CO2 methanation reaction by using distributor type membrane reactor. Catalysis Today, 462, Article 115569. https://doi.org/10.1016/j.cattod.2025.115569

Image Credits:

Mikihiro Nomura from Shibaura Institute of Technology, Japan

Keywords:

Environmental sciences, Chemistry, Chemical engineering, Energy, Sustainable development, Climate change, Materials science, Nanotechnology, Environmental engineering, Renewable energy