In the world of material science and engineered structures, breakthroughs often unfurl gradually, through incremental advancements rather than sudden leaps. Yet, a transformative moment may be upon us with the emergence of mechanical metamaterials—engineered structures exhibiting unparalleled properties not found in natural materials. Spearheaded by a collaborative research team from the University of Michigan and the Air Force Research Laboratory (AFRL), recent developments have demonstrated the power of intricate 3D-printed tubes to effectively suppress unwanted vibrations, potentially revolutionizing multiple engineering domains.

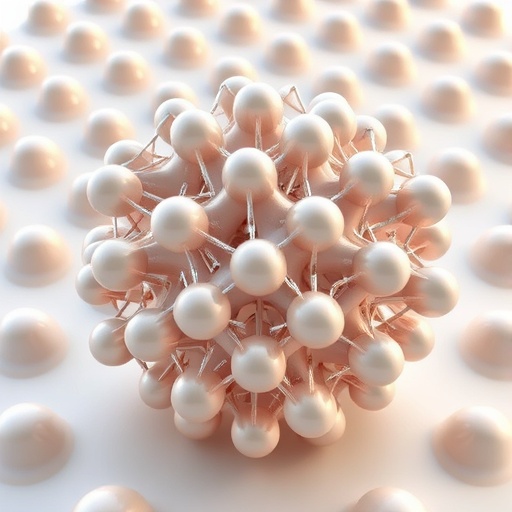

At the heart of this innovation lies an elegant fusion of geometry, physics, and cutting-edge manufacturing technology. Mechanical metamaterials owe their extraordinary capabilities not to chemical composition alterations but to deliberate architectural design. The researchers employed a sophisticated structure known as a “kagome tube,” named after the traditional Japanese basket weaving pattern, which exhibits a complex lattice arrangement that intrinsically controls mechanical wave propagation. These tubes passively isolate vibrations by exploiting their meticulously crafted geometry, representing a shift away from conventional materials that rely solely on chemical properties for performance enhancement.

Vibration isolation plays a critical role in myriad applications ranging from transportation systems and civil infrastructure to aerospace and defense technologies. Traditional approaches frequently depend on dampers or active control systems, which often add complexity and weight. The kagome tube structures promise a passive, structurally embedded solution, potentially offering lightweight yet effective alternatives. This breakthrough embodies years of cumulative theoretical insights and computational models finally brought to life through the precision of modern 3D printing, enabling tangible prototypes with unprecedented geometric complexity.

James McInerney, a research associate at AFRL and a former University of Michigan postdoctoral fellow, emphasizes the novelty in their ability to physically realize these designs. The team’s success in fabricating intricate kagome tubes from printed nylon marks a pivotal advancement that goes beyond theory. This hands-on verification demonstrates that engineered topological properties—once confined to abstract computations—can manifest at a meaningful macroscopic scale, with immediate real-world applicability in controlling physical phenomena like mechanical vibrations.

The research is grounded in foundational principles of structural engineering dating back to the 19th century, notably the work of James Clerk Maxwell. Maxwell’s pioneering investigations into mechanical stability and lattice structures laid the theoretical groundwork for what are now called Maxwell lattices—networked configurations that balance rigidity and flexibility through geometry. Building on Maxwell’s insights, the team explored newer physics concepts, particularly topological phases of matter, which have gained traction in explaining novel material behaviors localized at edges and boundaries.

Topology, initially a purely mathematical field, has emerged as a powerful lens through which researchers understand and harness exotic physical behaviors. The kagome tubes exploit topological polarization, a property that governs the directional transmission of mechanical waves, effectively localizing vibrations and preventing their propagation through the structure. This discovery reflects a growing understanding that material responses can be sculpted by geometry in ways previously unimaginable, opening new avenues for device development.

Beyond the striking visual appeal of the kagome structures—reminiscent of a folded chain-link fence rolled into tubes—the team’s work encapsulates a broader vision for precision manufacturing. Leveraging advancements in additive manufacturing, they envision a future where materials are custom architectured from the ground up to deliver tailored properties. This approach transcends mere material substitution, instead focusing on maximizing the efficacy of existing materials like metals and polymers through architectural ingenuity.

While the research represents a remarkable leap, it also underscores inherent trade-offs. The study revealed a notable inverse relationship between the effectiveness of vibration suppression and the structural load-bearing capacity of the tubes. This tension poses design challenges that must be addressed before widespread adoption, as practical applications often demand both mechanical robustness and vibrational control. Nevertheless, these findings serve as a valuable roadmap for future inquiries into optimizing performance parameters.

Crucially, as these exotic materials transition from lab prototypes to potential commercial use, there is a pressing need for novel testing frameworks. Traditional material characterization methods fall short when faced with topologically complex structures that exhibit behaviors fundamentally distinct from classical counterparts. Recognizing this, the team is pioneering new paradigms in experimental assessment and design integration—essential groundwork that will dictate how such metamaterials are understood, optimized, and implemented at scale.

Collaboration has been key to the project’s success. Alongside McInerney, university and laboratory partners including physics professor Xiaoming Mao and mechanical engineering associate professor Serife Tol have brought interdisciplinary expertise to refine both theoretical models and fabrication techniques. The convergence of physics, mechanical engineering, and manufacturing showcases the necessity of a broad scientific dialogue to tackle complex challenges inherent in these emerging materials.

This research is also emblematic of a sustained investment in defense-related innovation, receiving federal support from agencies such as DARPA and the Office of Naval Research. Such backing reflects the strategic importance of materials that can enhance survivability and functionality under dynamic mechanical stresses, crucial in aerospace, military vehicles, and infrastructure subjected to vibrational loads.

Ultimately, the kagome tube initiative exemplifies how merging age-old scientific principles with modern technological capabilities can unlock unprecedented material properties. It heralds an era where harnessing the power of geometry—not chemistry—is paramount in material design. These developments promise to inspire new classes of materials engineered for specific tasks, weaving together the elegance of mathematics, physics, and manufacturing into transformative solutions for vibration isolation and beyond.

Subject of Research: Mechanical metamaterials and vibration isolation using 3D-printed kagome tube structures.

Article Title: Topological polarization of kagome tubes and applications towards vibration isolation.

News Publication Date: 14-Oct-2025.

Web References: http://dx.doi.org/10.1103/xn86-676c

Image Credits: James McInerney, Air Force Research Laboratory.

Keywords: mechanical metamaterials, vibration isolation, 3D printing, kagome tube, topological polarization, Maxwell lattices, structural engineering, additive manufacturing, topological phases, materials science.