In the quest for sustainable energy alternatives, biobased fuels have emerged as a prominent focus in recent times. The potential of biodiesel as a cleaner, renewable energy source is drawing attention from researchers across the globe. A significant breakthrough in this area has been realized through innovative methods of biodiesel production. One particularly interesting study led by a team of researchers, including Oza, Mathur, and Kodgire, delves into ultrasound-assisted methods for producing biodiesel from blended castor and Karanja oils using a nano-magnetic catalyst, Sr-Fe3O4.

This pioneering approach seeks to optimize production efficiency while enhancing the overall kinetics of the process. Biodiesel production typically involves the transesterification of triglycerides, which can be derived from various oils. Castor oil, known for its high ricinoleic acid content, presents unique properties, while Karanja oil, derived from the Karanja tree, is also rich in essential fatty acids. The combination of these two oils promises to yield a biodiesel product with advantageous characteristics.

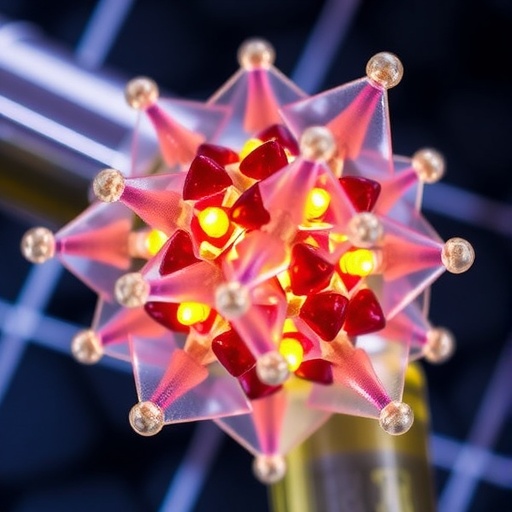

The research team focused on a critical aspect of biodiesel production—catalyst efficiency. Here, they employed a nano-magnetic catalyst composed of strontium iron oxide (Sr-Fe3O4), which not only accelerates the transesterification reaction but also facilitates easier recovery and reuse due to its magnetic properties. This innovative catalyst system provides a double advantage: enhancing the reaction kinetics and promoting sustainability by reducing catalyst waste.

A significant challenge in the biodiesel production process is optimizing the reaction conditions to achieve maximum yield. The research team employed ultrasound-assisted techniques, which have been proven to intensify chemical reactions by generating cavitation bubbles within the liquid medium. These bubbles collapse violently, leading to high local temperatures and pressures that can significantly enhance reaction rates. This method presents a dynamic approach to traditional biodiesel synthesis, illustrating the fusion of novel technologies with established chemical engineering principles.

The study presented a detailed kinetic analysis of the transesterification process under various operating conditions, which allowed the researchers to pinpoint optimal parameters that maximize biodiesel yield. The kinetics of biodiesel synthesis are influenced by several factors, including temperature, reaction time, oil-to-methanol molar ratio, and catalyst concentration. Through systematic experimentation, the researchers meticulously analyzed these variables to craft a comprehensive optimization strategy.

Furthermore, the findings of this study indicate that ultrasound technology can drastically reduce reaction times compared to conventional methods. Standard transesterification processes may require several hours to produce biodiesel efficiently, but employing ultrasound waves can cut this down to mere minutes. This remarkable enhancement is quintessential for industrial applications, where time and efficiency are of the essence.

In addition to exploring the technical compatibility of the nano-magnetic catalyst and the efficacy of ultrasound, the research also delves into the physicochemical properties of the produced biodiesel. The team meticulously assessed factors such as viscosity, density, and oxidative stability, which are critical for ensuring that the biodiesel meets the required specifications for use in diesel engines. Their analyses confirmed that the biodiesel derived from blended castor and Karanja oils exhibited superior properties, suggesting its feasibility as a sustainable fuel alternative.

The environmental implications of this research are profound. Biodiesel derived from non-edible plant oils like castor and Karanja not only contributes to reducing reliance on fossil fuels but also promotes the use of agricultural residues. By harnessing oils that are often considered waste products, the researchers advocate a more circular economy within the energy sector. This aligns with broader environmental goals aimed at reducing carbon footprints and establishing a more sustainable future.

Economic considerations also play a crucial role in determining the viability of biodiesel production. The researchers have acknowledged that traditional biodiesel manufacturing processes can be cost-prohibitive due to high raw material and operational costs. However, by utilizing waste oils and integrating ultrasound technology, this study signals a shift towards more cost-effective methods that could enhance the overall economic feasibility of biodiesel production.

The work by Oza and colleagues is representative of a broader trend where advanced materials science meets renewable energy development. As the global community grapples with the harsh realities of climate change, such innovations in biodiesel production methods are crucial in diversifying the energy portfolio and making strides toward sustainability. This study shows promise not only for the biodiesel industry but also offers insights into how emerging technologies can be leveraged across various chemical processes.

In summary, the research encapsulates a significant step forward in the quest for efficient and sustainable biodiesel production methods. The integration of an ultrasound-assisted approach with a nano-magnetic catalyst heralds a new era in biomass conversion technologies. With implications that stretch well beyond academic interest, this research opens avenues for creating cleaner, more sustainable fuels through innovative practices. The team’s findings undoubtedly contribute to the momentum needed in advancing biodiesel as a vital alternative for sustainable energy.

As the energy landscape continues to evolve, the importance of studies such as these cannot be overstated. They exemplify the intersection of creativity, engineering, and science, inspiring future research avenues and encouraging a more extensive dialogue on biofuels. The ultimate goal is to forge pathways toward a sustainable future powered by renewable energy, with biodiesel poised to play a crucial role.

In conclusion, as the world shifts its gaze towards greener energy alternatives, the contribution of innovative research such as that conducted by Oza, Mathur, and Kodgire is not only timely but necessary. Their findings present a hopeful outlook on the viability and efficiency of biofuels, resonating with ongoing efforts to combat climate change. Ultimately, the journey toward a more sustainable energy future relies on continued innovations and collaborative efforts, with studies like this serving as a beacon for both research and industrial applications alike.

Subject of Research: Ultrasound-assisted biodiesel production from blended castor and Karanja oil using a nano-magnetic catalyst.

Article Title: Ultrasound-assisted biodiesel production of blended castor and Karanja oil using nano-magnetic Sr-Fe3O4 catalyst: optimization and kinetic study.

Article References:

Oza, S., Mathur, C., Kodgire, P. et al. Ultrasound-assisted biodiesel production of blended castor and Karanja oil using nano-magnetic Sr-Fe3O4 catalyst: optimization and kinetic study.

Environ Sci Pollut Res (2025). https://doi.org/10.1007/s11356-025-37023-w

Image Credits: AI Generated

DOI: 10.1007/s11356-025-37023-w

Keywords: biodiesel, ultrasound-assisted production, castor oil, Karanja oil, nano-magnetic catalyst, Sr-Fe3O4, optimization, kinetic study.