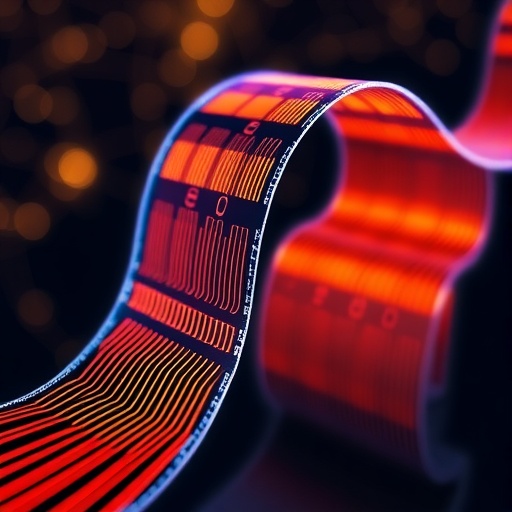

In the rapidly evolving landscape of flexible electronics, a groundbreaking study has emerged, promising to revolutionize how stretchable and conductive connections are constructed. A research team led by Zhao, Ruan, and Li has unveiled a universal method that overcomes longstanding technical challenges in integrating durability and conductivity in flexible electronic devices. This breakthrough heralds a new era for wearable technology, biomedical devices, soft robotics, and myriad applications demanding reliable, mechanically resilient electronic interconnections.

Flexible electronics have captured imaginations worldwide for their immense potential to seamlessly integrate technology with the human body, textiles, and complex surfaces. However, their widespread adoption has been hindered by intrinsic difficulties in ensuring both high electrical conductivity and mechanical stretchability within the connecting elements. Traditional approaches have often faced trade-offs—materials providing excellent conductivity typically lack elasticity, while elastomers and polymers offering flexibility show poor electron transport. The new universal method addresses this fundamental materials conundrum through innovative engineering at micro- and nanoscale levels.

At the heart of Zhao and colleagues’ approach is a novel fabrication technique that creates highly stretchable conductive pathways without compromising electrical performance. This method employs a composite architecture that integrates conductive nanomaterials within an elastomeric matrix, orchestrated through a carefully optimized patterning strategy. By controlling the spatial distribution and mechanical loading of conductive fillers, the researchers effectively eliminate microcracking and delamination issues that usually plague flexible interconnects during repeated deformation cycles.

The significance of this technique lies in its universality and scalability. Unlike prior methods tailored to specific use cases or limited material systems, this platform can be adapted to various conductive components—including metallic nanowires, carbon-based nanostructures, and emerging two-dimensional materials. Consequently, electronic designers can now select or engineer conductive fillers based on device requirements without sacrificing mechanical robustness. This flexibility ushers in new possibilities for customizing devices ranging from ultrathin skin-mounted sensors to foldable displays and implantable medical electronics.

Experimentally, the team demonstrated that their stretchable interconnections maintain electrical conductivity under tensile strains exceeding 100%. Their custom-fabricated test devices endured thousands of stretching cycles with negligible loss in conductivity, surpassing the performance benchmarks of existing flexible interconnect technologies. Mechanical characterization confirmed the composite’s resilience, exhibiting low hysteresis and remarkable fatigue resistance. These properties translate directly into enhanced reliability and operational lifespan for flexible electronics subjected to dynamic human motion or environmental stresses.

From a materials science perspective, the researchers elucidated the interplay between filler morphology, interface adhesion, and matrix elasticity that governs the composite’s conductive network stability. Through state-of-the-art imaging and spectroscopy, they visualized nanoscale deformation mechanisms, revealing how conductive pathways dynamically reconfigure without fracturing under mechanical load. This profound understanding paves the way for future innovations in self-healing or reconfigurable electronics, where dynamic adaptation to stress is critical.

Moreover, the fabrication process is compatible with established manufacturing pipelines, such as extrusion printing, lithography, and roll-to-roll processing. This compatibility means the technology can be integrated into commercial flexible electronics production without excessive cost or complexity increases. The potential for mass production ensures that this advancement can quickly permeate markets, accelerating the transition from concept devices to everyday, reliable flexible electronics.

The implications extend beyond consumer electronics and healthcare. Soft robotics, a burgeoning field that relies on compliant and stretchable sensors and actuators, stands to benefit enormously from such robust conductive interconnections. Enhancing robotic skin sensitivity and control with durable electronics will enable more sophisticated interactions between machines and their environments, advancing autonomy and safety. Additionally, aerospace and automotive industries could utilize flexible, vibration-resistant electronics to improve monitoring and control systems under harsh mechanical conditions.

Crucially, this research addresses a bottleneck in flexible system integration. Electrical connections are, by nature, critical weak points prone to failure during bending, twisting, or stretching. By creating a universal, durable connective infrastructure, the entire ecosystem of flexible electronic components—active semiconductors, energy harvesters, and sensing elements—can be linked more reliably. This systemic improvement reduces device failure rates and maintenance burdens, key factors for wearables that interact intimately with the body.

Collaboration among multidisciplinary experts was integral to this achievement. The team combined expertise in nanomaterial synthesis, polymer chemistry, mechanical engineering, and electronics packaging. This synergy enabled a holistic approach to resolving physical and electrical challenges, setting an exemplary standard for interdisciplinary innovation in flexible electronics. Beyond technical merits, the research highlights the importance of versatile fabrication techniques in accelerating technology adoption.

Looking ahead, several intriguing avenues for further development naturally emerge from this study. Incorporating functional nanomaterials that enable additional capabilities, such as sensing environmental stimuli or energy storage, within the stretchable connections could result in multifunctional flexible platforms. Likewise, integrating stretchable electronics with emerging biointerfaces for continuous health monitoring or neural recording benefits substantially from these dependable and elastic conductive pathways.

While the current approach predominantly focuses on baseline electrical conductivity and mechanical resilience, future work might explore optimizing thermal management and electromagnetic interference shielding within flexible interconnects. Balancing these factors will be essential for high-performance applications, such as flexible antennas or power electronics, where thermal dissipation and signal integrity are paramount. The universal framework developed lays a solid foundation for such sophisticated material system engineering.

The implications of this work resonate beyond scientific communities into societal and ethical domains. As wearable devices become increasingly ubiquitous with improved reliability and comfort, data privacy, security, and accessibility will gain prominence. Ensuring that these advanced flexible electronics facilitate positive user experiences without introducing vulnerabilities requires continued interdisciplinary collaboration between engineers, data scientists, and policy makers.

In sum, Zhao, Ruan, Li, and their collaborators have delivered a technical tour de force that resolves core limitations in stretchable and conductive flexible electronics. Their universal method harmonizes material innovation, mechanical robustness, and manufacturability, constituting a pivotal step towards truly ubiquitous and reliable flexible electronic devices. As this technology integrates into commercial and biomedical applications, it promises to transform how we interact with electronic devices—making them more adaptable, resilient, and seamlessly integrated into our daily lives.

This pioneering research, published in npj Flexible Electronics, marks a milestone reflecting the profound power of cross-disciplinary efforts to tackle complex material challenges. The universal conductive connection methodology introduced herein not only pushes boundaries but inspires a vision of future electronics that conform effortlessly to human bodies, irregular surfaces, and dynamic environments. It stands as a beacon inviting further exploration and innovation in an exciting, fast-moving scientific frontier.

Subject of Research: Stretchable and conductive connections in flexible electronics

Article Title: A universal method for constructing stretchable and conductive connections in flexible electronics

Article References:

Zhao, Y., Ruan, Q., Li, T. et al. A universal method for constructing stretchable and conductive connections in flexible electronics. npj Flex Electron 9, 63 (2025). https://doi.org/10.1038/s41528-025-00449-w

Image Credits: AI Generated