In the high-stakes world of industrial manufacturing and infrastructure maintenance, ensuring structural integrity is critical. Hidden microscopic defects within materials—whether in semiconductor chips, energy infrastructure, automotive components, or steel frameworks—can undermine safety and performance in catastrophic ways. Traditional non-destructive testing (NDT) methods, which utilize physical sensors such as ultrasonic or electromagnetic waves to assess internal material conditions without causing damage, have long served as a vital tool for detecting these flaws. However, the precision of these techniques is often compromised by the complex realities of physical environments, including varying material properties, geometry, and external noise, which distort the signals and pose fundamental limits on accurately mapping defects.

A monumental breakthrough from researchers at Chung-Ang University in Seoul, South Korea, now promises to transcend these limitations using cutting-edge artificial intelligence (AI). Led by Prof. Sooyoung Lee, Assistant Professor and Principal Investigator of the Industrial Artificial Intelligence Laboratory, the team has developed DiffectNet, a diffusion-enabled conditional target generation network designed to revolutionize ultrasonic non-destructive testing with unprecedented clarity and fidelity. By leveraging generative AI, DiffectNet can reconstruct and highlight internal defects within materials with a precision that outperforms conventional methods—ushering in a new era of industrial reliability and safety.

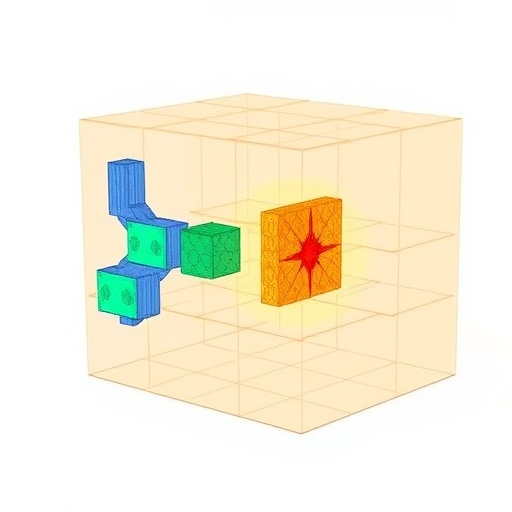

DiffectNet operates by harnessing diffusion modeling, a powerful generative AI technique that simulates the stochastic process of data transformation from noise to defined structure. Conditioned on ultrasonic signals, this network generates highly detailed internal images of defects, effectively learning to ‘see’ what traditional sensors and algorithms cannot resolve. This approach circumvents the physical constraints that plague classical imaging techniques by making sense of complex, distorted sensor data through deep learning models trained on virtually engineered defect patterns. The result is a real-time, defect-aware diagnostic tool that can both detect and reconstruct microcracks and flaws with exceptional granularity.

The potential applications of such technology are extensive and transformative. In industrial power plants where small internal cracks can trigger devastating failures, DiffectNet could enable continuous, real-time internal monitoring of critical components, providing operators with early-warning signals that preempt accident scenarios. In semiconductor fabrication and advanced manufacturing, the AI-driven ability to virtually reconstruct internal defects without halting production lines promises a dramatic boost in quality control and operational efficiency. This technology also portends smarter civil infrastructure management, where continuous monitoring of bridges, buildings, and other structures could proactively address safety risks before visible signs emerge.

Moreover, this AI advancement is not simply an incremental improvement to existing NDT practices but a fundamental rethinking of how internal defect imaging is performed. Prof. Lee emphasizes the paradigm-shifting nature of the work: “DiffectNet is not just the application of AI to engineering problems; it is a reinvention of the diagnostic process. Our generative AI framework transcends the physical limitations inherent in traditional sensing by reconstructing hidden cracks inside structures in real time.” By treating AI as an active agent in material health monitoring, this research redefines the boundaries of what engineering systems can achieve.

The technical sophistication of DiffectNet lies in its novel integration of conditional diffusion models that adaptively generate defect images guided by raw sensor inputs. Unlike conventional signal processing methods that attempt to invert noisy sensor data directly, this generative model builds representations through iterative denoising and feature extraction, capturing nuanced defect characteristics encoded in indirect measurements. This allows DiffectNet to accurately predict defect locations, sizes, and morphologies, thus opening new avenues for precision engineering diagnostics.

Aside from its technical prowess, DiffectNet illustrates the growing synergy between artificial intelligence and traditional engineering disciplines. It embodies the vision of “intelligent engineering,” where AI-driven models and data-enabled reasoning capabilities extend human perception beyond physical sensor limitations. By acting as a surrogate “eye” within structures, the technology empowers operators with insights previously unattainable, supporting safer design, maintenance, and lifecycle management in industries where reliability is mission-critical.

Looking ahead, the impact of DiffectNet and similar technologies could reshape global industrial practices. The ability to detect defects preemptively and reconstruct them in real time affords industries the dual benefits of enhanced safety and operational continuity. Power generation, aerospace, civil infrastructure, semiconductor manufacturing, and automotive sectors stand to benefit significantly. Ultimately, this breakthrough also aligns with broader trends toward smart cities and digital twins, where AI interprets and continuously models physical systems, enhancing resilience at societal scales.

Prof. Sooyoung Lee’s team is pushing the frontier further with plans to refine AI architectures and expand datasets for even more robust defect characterization across various materials and defect typologies. They envision a future where AI-enabled engineering systems autonomously diagnose, predict, and even suggest remediation actions for structural anomalies. This progression marks the next evolutionary step of engineering, where artificial intelligence transforms from a tool into a proactive collaborator in solving complex, real-world challenges.

The advent of DiffectNet and its demonstrated capabilities underscore a profound message for the engineering and scientific communities: the convergence of generative AI with physical sensing heralds an era where previously invisible flaws are rendered visible, interpretable, and actionable in real-time. This shift not only enhances operational safety and efficiency but will likely redefine standards across all industries reliant on structural integrity and performance.

By bridging the gap between signal noise and reliable defect imaging, the AI-powered system embodies a new paradigm that will safeguard lives, preserve infrastructural assets, and stimulate innovation. DiffectNet stands as a testament to the power of interdisciplinary collaboration and AI-driven ingenuity in reshaping the future of industrial reliability and safety.

Subject of Research:

Not applicable

Article Title:

DiffectNet: diffusion-enabled conditional target generation of internal defects in ultrasonic non-destructive testing

News Publication Date:

1 November 2025

References:

DOI: 10.1016/j.ymssp.2025.113454

Image Credits:

Credit: Prof. Sooyoung Lee from the School of Mechanical Engineering at Chung-Ang University

Keywords:

Artificial intelligence, Mechanical engineering, Materials science, Signal processing, Aerospace engineering, Civil engineering, Semiconductors, Applied physics, Computer modeling, Manufacturing, Electrical engineering