In a groundbreaking advancement at the intersection of materials science and acoustics, researchers have unveiled a novel triboelectric acoustic transducer fabricated through mechanically guided 4D printing. This innovative device not only operates as a self-powered acoustic sensor but also demonstrates intelligent voice recognition capabilities. The work, recently published in npj Flexible Electronics, represents a significant leap forward in flexible electronics and energy harvesting technologies, potentially revolutionizing how we integrate sound sensing interfaces into wearable and flexible devices.

The cornerstone of this research is the integration of triboelectric nanogenerators (TENGs) with mechanically guided 4D printing techniques. Triboelectricity—an effect where certain materials generate electric charge through contact and separation—offers a unique platform for converting mechanical energy from sound waves directly into electrical signals without the need for external power sources. The researchers exploited this phenomenon to create an acoustic transducer that can simultaneously harvest energy from ambient sound and function as a sensitive microphone.

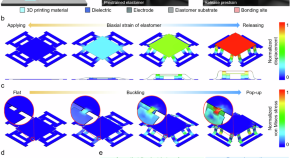

Mechanically guided 4D printing—a cutting-edge manufacturing technology where printed structures morph into predetermined 3D shapes upon mechanical stimulus—was employed to fabricate complex, flexible architectures that enhance the acoustic transducer’s sensitivity and durability. Unlike traditional 3D printing, 4D printing incorporates a time or stimulus-dependent transformation, enabling dynamic and reconfigurable designs suitable for wearable applications. This printing method particularly suits the fabrication of intricately patterned triboelectric layers that improve the interaction between vibrating surfaces and contact materials.

The design features a multilayered structure composed of elastomeric substrates embedded with microstructured triboelectric surfaces. When exposed to acoustic waves, these microstructures deform, causing periodic contact and separation between layers, which generate electrical pulses corresponding to sound vibrations. Remarkably, this system not only captures subtle acoustic signals with high fidelity but also produces sufficient electrical output to power the sensing module itself, eliminating reliance on traditional batteries or external power supplies.

One of the most compelling aspects of this research is the device’s intelligent voice recognition capability. By integrating machine learning algorithms with the triboelectric output signals, the system can differentiate and recognize spoken commands with impressive accuracy. This capability paves the way for fully self-powered, smart acoustic interfaces suitable for Internet of Things (IoT) devices, wearable health monitors, and hands-free control systems in environments where charging or battery replacement is impractical.

From a mechanical perspective, the device exhibits remarkable flexibility and durability, critical metrics for wearable or implantable electronics. The mechanically guided 4D printing process ensures that the final device can sustain repeated bending, stretching, and compressive forces without degradation of its acoustic or electrical performance. This robustness is crucial for long-term use in dynamic and physically demanding environments, such as those encountered in biomedical monitoring or human-machine interfaces.

The authors demonstrated the device’s efficacy through a series of acoustic sensing experiments involving varying frequencies and amplitudes of sound waves. The triboelectric acoustic transducer produced distinguishable electrical signals corresponding to different acoustic patterns, confirming its capability to serve as a precise sound detector. Moreover, energy harvesting tests showed that the device could continuously power its own signal processing circuitry using harvested acoustic energy alone, underscoring the potential for fully autonomous operation.

The research also highlights the scalability of the manufacturing approach. Mechanically guided 4D printing allows rapid prototyping and mass fabrication of complex multilayer triboelectric devices without the need for expensive, cleanroom-intensive semiconductor processes. This scalability is pivotal for the widespread adoption of flexible acoustic sensors across consumer electronics, smart textiles, and environmental monitoring systems.

Furthermore, the study details the theoretical underpinnings of the triboelectric effect in the engineered microstructures, supported by computational models that predict the device’s electrical output under diverse acoustic stimuli. These models informed iterative design improvements, optimizing the spatial arrangement and geometries of the triboelectric layers to maximize energy conversion efficiency and acoustic sensitivity.

Importantly, the triboelectric acoustic transducer demonstrated compatibility with various substrates, including biocompatible materials, opening avenues for integration into health-monitoring wearables. This compatibility ensures that future iterations could be used to detect respiratory ailments, voice pathologies, or act as silent speech interfaces for individuals with speech impairments.

The novel combination of mechanical design, advanced printing technologies, and triboelectric energy harvesting embodies the spirit of interdisciplinary innovation. It bridges the gaps between additive manufacturing, flexible electronics, acoustics, and artificial intelligence, culminating in a device that is not only functionally superior but also cost-effective and environmentally sustainable given its battery-free operation.

As intelligent voice interfaces become increasingly pivotal in technology ecosystems, self-powered flexible acoustic sensors address crucial challenges in power consumption and device longevity. The current research thereby lays a foundation for next-generation human-machine interaction devices that are seamlessly integrated with the human body and the ambient environment, operating sustainably without cumbersome energy demands.

Looking forward, the team envisions expanding the device’s functionalities by incorporating multimodal sensing capabilities, such as simultaneous detection of pressure, temperature, and humidity, alongside acoustic signals. Such multifunctional sensing platforms would further enhance the applicability of this technology in the burgeoning fields of personalized health diagnostics and ambient intelligence.

Moreover, integrating more advanced machine learning techniques directly into the flexible electronics stack could enable real-time sound processing and contextual awareness, potentially allowing devices that can adapt and learn from their environments autonomously. Such developments would place this triboelectric acoustic system at the forefront of smart flexible electronics.

In conclusion, the mechanically guided 4D printed triboelectric acoustic transducer represents a major milestone in self-powered, flexible sensor technology. It showcases how intelligent design and innovative manufacturing approaches can converge to produce devices capable of revolutionizing voice recognition applications. As this technology matures, it promises to catalyze significant shifts in how we interact with and power our wearable and ambient electronic systems.

Subject of Research:

Mechanically guided 4D printing of self-powered triboelectric acoustic transducers with integrated intelligent voice recognition.

Article Title:

Mechanically guided 4D printing of a triboelectricity-driven acoustic transducer for self-powered and intelligent voice recognition

Article References:

Kam, D., Gwon, G., Ra, Y. et al. Mechanically guided 4D printing of a triboelectricity-driven acoustic transducer for self-powered and intelligent voice recognition. npj Flex Electron 9, 73 (2025). https://doi.org/10.1038/s41528-025-00451-2

Image Credits: AI Generated