In a groundbreaking development that could herald a new era for environmentally sustainable materials, researchers at the University of Southern California’s Viterbi School of Engineering have engineered a novel plastic substitute derived from a mineral abundant in seashells. This innovative biodegradable composite not only promises to mitigate the pervasive issue of marine plastic pollution but also offers practical industrial utility with robustness comparable to conventional plastics. By harnessing calcium carbonate extracted from seashells and integrating it into a biodegradable polymer matrix, this research pushes the boundaries of materials science toward a greener future.

Global plastic pollution has reached staggering levels, with an estimated 8 to 10 million metric tons of plastic debris entering the oceans annually, according to UNESCO. This influx contributes to approximately 80% of marine pollution, posing irreversible threats to aquatic ecosystems and biodiversity. Amid mounting environmental crises, the pressing demand for sustainable alternatives to conventional plastics has never been more urgent. Recognizing this critical gap, Eun Ji Chung, the Dr. Karl Jacob Jr. and Karl Jacob III Early-Career Chair at USC Viterbi, spearheaded an effort to develop a biocompatible, biodegradable plastic substitute by combining naturally derived mineral components with innovative polymer chemistry.

Chung’s team employed calcium carbonate (CaCO₃), a mineral that imparts hardness to seashells, as a reinforcing agent embedded within poly(1,8-octanediol-co-citrate), known as POC. POC is an FDA-approved, biodegradable polymer initially used for orthopedic fixation devices due to its favorable mechanical properties and biocompatibility. Leveraging her extensive background in engineering nanoparticles for clinical applications, Chung adapted earlier graduate research focused on citric acid-based biodegradable polymers. This polymer is synthesized through polycondensation of citric acid and 1,8-octanediol, forming a cross-linked network that can be thermally cured to achieve desired mechanical strength.

What distinguishes this research is the substitution of hydroxyapatite—that is prevalent in bone tissue—with calcium carbonate from seashells, which differs structurally and chemically. Seashell-derived calcium carbonate, primarily composed of calcite or aragonite forms, imparts stiffness and durability to the composite while ensuring biodegradability in marine environments. The blending process involves uniformly dispersing micron-scale calcium carbonate particles into the POC prepolymer matrix, followed by thermal curing that polymerizes the mixture into a cohesive, plastic-like material named POC-CC.

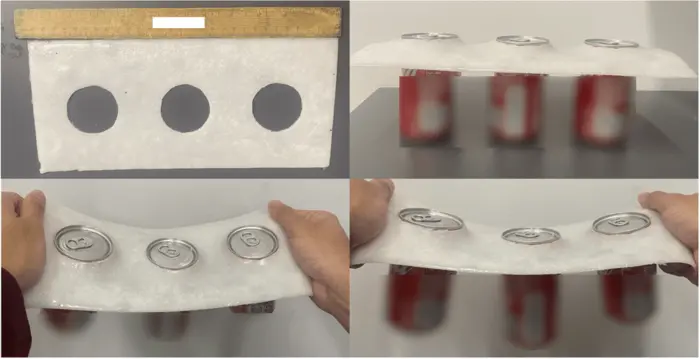

Physically, this composite material exhibits properties akin to traditional plastics. Initially sticky and gum-like due to the polymer constituents, the addition of calcium carbonate and subsequent heat treatment yields a solid, robust composite. The team demonstrated its practical potential by fabricating prototypes of beverage holder rings—the notorious "six-pack rings" known for their detrimental impact on marine wildlife—which displayed sufficient mechanical rigidity to fulfill their supporting function. This proof-of-concept underscores the composite’s applicability for replacing conventional plastics in various single-use products.

Beyond mechanical strength, the environmental compatibility of POC-CC was rigorously tested. The researchers synthesized its variants with different calcium carbonate concentrations to investigate degradation patterns in simulated ocean water over six months. Key measurements included mass loss rates, surface morphology changes, and the impact of degradation products on seawater pH. Results indicated accelerated degradation proportional to increased POC content, while the calcium carbonate component acted as a buffering agent, stabilizing the pH conditions within the marine-like environment. Maintaining pH neutrality is vital to prevent disrupting delicate marine ecologies during the degradation process.

Importantly, the composite’s impact on marine microorganisms was meticulously examined using cultures of Scenedesmus species, a genus of green algae emblematic of marine primary producers. Incubation alongside POC-CC in artificial seawater showed high cell viability even after prolonged exposure, signifying the absence of cytotoxic effects or ecological harm. This biocompatibility contrasts sharply with microplastics, which often leach toxic additives and cause physical damage to marine life. POC-CC’s inherently benign degradation byproducts could thereby alleviate one of the most pressing environmental issues stemming from plastic pollution.

Looking ahead, Chung and her team aim to optimize this composite by engineering a second-generation material with enhanced degradation kinetics. Accelerating the breakdown process while preserving mechanical integrity will further ensure that the plastic substitute does not persist dangerously in marine systems after fulfilling its functional role. Potential future applications extend to manufacturing biodegradable straws that outperform bamboo or paper alternatives in strength and durability, yet avoid the environmental pitfalls of metal or conventional plastic straws.

This exploration into mineral-polymer composites highlights the transformative potential of bioinspired materials science. By bridging natural materials with synthetic innovations, researchers can pioneer solutions that reconcile industrial needs with ecological stewardship. As the planet grapples with escalating plastic waste crises, such breakthroughs offer hope for sustainable materials that embed environmental considerations into their molecular architecture rather than treating pollution as an afterthought.

The publication of these findings in MRS Communications lends further credibility and disseminates the research within the scientific community, fostering cross-disciplinary collaboration to refine and scale this technology. Funding from the National Oceanic and Atmospheric Administration along with the USC Sea Grant Program underscores the societal importance attributed to creating marine-safe materials that can alleviate the ocean’s plastic burden.

In sum, the POC-CC composite represents a promising step forward in replacing conventional plastics with biodegradable, biocompatible, and functionally robust alternatives derived from renewable natural resources. As research progresses, the integration of mineral-derived components into polymer matrices may pave the way for a new generation of sustainable plastics, harmonizing human industrial activities with the ecological balance of our oceans.

Subject of Research: Not applicable

Article Title: Calcium carbonate‑based biodegradable composites as an alternative material to industrial plastics

News Publication Date: 25-Feb-2025

Web References: 10.1557/s43579-025-00695-z

References: Published in MRS Communications

Image Credits: The Chung Lab at USC Viterbi School of Engineering

Keywords: Marine biology, Water pollution, Biodegradable plastics, Synthetic polymers