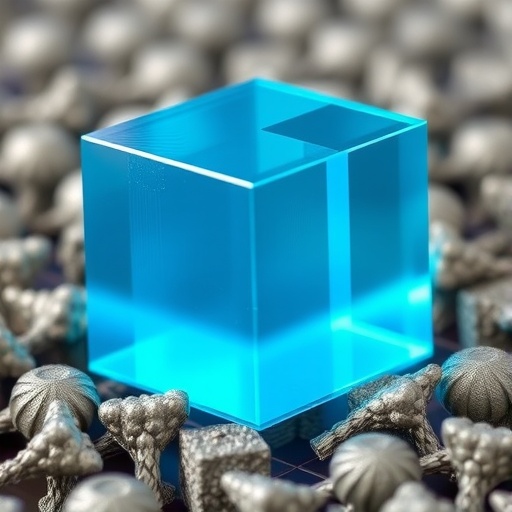

The realm of solid materials is characterized not only by perfectly ordered crystalline structures but also by the chaos of disordered glasses. Between these two states lies a vast and intriguing transitional spectrum, composed of crystalline grains enveloped by disordered boundaries. These unique structures often feature crystalline grains interspersed with amorphous regions, particularly notable when these disordered areas are only a single atomic layer thick. In such instances, we witness the familiar appearance of polycrystals, while thicker disordered regions give rise to the broader category of crystalline-amorphous composites. This fascinating interplay between crystalline and amorphous structures opens up new avenues for understanding material properties and their associated mechanical behaviors.

Crucially, the mean diameter of crystalline grains, denoted as D, along with the mean grain boundary thickness, represented as l, serve as fundamental parameters that define the structural characteristics of materials within this transitional region. Extensive research has already demonstrated how variations in grain diameter can significantly influence mechanical properties. For instance, a decrease in crystallite diameter typically leads to an increase in yield strength, a phenomenon articulately described by the well-known Hall–Petch relationship. However, this increase in strength is often followed by a decrease when diameter falls below a certain threshold, exemplifying the inverse Hall–Petch behavior. Such striking phenomena establish a compelling relationship between microstructure and material properties.

Despite the wealth of knowledge surrounding the influence of grain diameter, the impact of grain boundary thickness on material properties remains an underexplored territory. This lack of focus can be attributed to the difficulties inherent in conducting experimental research, particularly in producing samples with varying grain boundary thicknesses. As pointed out by Yilong Han, a researcher from the Hong Kong University of Science and Technology, the barriers to understanding the effects of grain boundary thickness extend beyond practical challenges. These barriers may also stem from terminological discrepancies and differing conceptual frameworks across the fields of materials science and engineering.

Addressing this somewhat overlooked dimension, Han and his research team embarked on a groundbreaking study utilizing computer simulations to gain insight into the mechanical properties of materials across a range of grain diameters and boundary thicknesses. Published in the September 2025 issue of National Science Review, their research systematically examines key properties such as strength, toughness, and elastic modulus in crystalline-amorphous composites. The first author of the study, Zhibin Xu, highlights the importance of narrowly defining and exploring the often-neglected thickness of grain boundaries alongside the diameter of crystalline grains.

Employing computer simulations across a structured parameter space of D and l, the research team extended the classical relationships between grain size and mechanical properties. Notably, the findings revealed a peak material strength when grain boundary thickness reaches approximately six atomic layers. Strikingly, this increase in thickness does not merely enhance strength; it also maximizes ductility, presenting an encouraging prospect for material scientists concerned with balancing these two often-competing properties—strength and ductility. This simultaneous improvement signifies a promising opportunity to sidestep the conventional strength-ductility tradeoff that has long perplexed engineers and scientists.

Delving deeper into the mechanisms at play, the study drew attention to the competition between two predominant plastic mechanisms: dislocation-dominated crystalline plasticity and shear transformation-dominated plasticity occurring within the amorphous regions. While dislocation movements underlie plastic deformation in crystalline structures, the amorphous phases experience different deformation processes. In single-component face-centered cubic materials, thick grain boundaries serve to inhibit dislocation nucleation and provide a repository for gliding dislocations, thereby augmenting both the strength and ductility of the material. In contrast, the behaviors of body-centered cubic or multi-component face-centered cubic materials tell a different tale; for these configurations, any increase in grain boundary thickness predominately leads to a softening of the material.

Intriguingly, recent advancements in material fabrication have allowed for the creation of alloys exhibiting significantly thick grain boundaries. Some of these materials have demonstrated the ability to exceed the maximum strength capabilities of their polycrystalline counterparts, while others have failed to do so. This variation in experimental outcomes reflects the complex interplay of structural parameters and reinforces the need for a deeper understanding of the influence of both D and l as independent variables. Through this focused investigation, the research team aims to provide clarity on these seemingly contradictory phenomena, granting new insights into the future design of solid materials characterized by superior mechanical properties.

In summary, the research spearheaded by Yilong Han and his team not only contributes to the existing body of knowledge regarding crystalline-amorphous composites but also sheds light on avenues for future investigations. By comprehensively analyzing the effects of grain diameter and boundary thickness in tandem, this work underscores the multifaceted nature of material properties—empowering materials scientists to pursue the design and development of advanced materials with high strength and exceptional ductility. Such advancements hold the potential for transformative applications across a variety of industries, underscoring the importance of continued exploration in this dynamic field.

Through their innovative approach, Han and his colleagues pave the way for a more nuanced understanding of solid material behaviors that will undoubtedly inspire further research and experimentation. As the desire for high-performance materials grows, it is the intricate understanding of these structural parameters that will catalyze advancements in creating the next generation of engineering materials.

With this research, we see a pivotal moment in materials science where the relationship between microstructural parameters has been reevaluated, laying the groundwork for future innovations that promise enhanced mechanical performance. The implications of this work reach far beyond academic understanding; they open the door to practical applications in engineering and manufacturing, ultimately paving the way for materials that meet the demands of tomorrow’s technology and infrastructure.

Subject of Research: Mechanical properties of crystalline-amorphous composites

Article Title: Title is not explicitly mentioned in the provided text.

News Publication Date: September 2025

Web References: http://dx.doi.org/10.1093/nsr/nwaf336

References: National Science Review

Image Credits: ©Science China Press

Keywords

Crystalline-amorphous composites, mechanical properties, grain diameter, grain boundary thickness, Hall–Petch relationship, dislocation dynamics, computer simulations.