A groundbreaking advancement in the field of frictionless transport has been achieved by researchers at YOKOHAMA National University, unveiling an untethered levitation device capable of high-speed omnidirectional movement on flat surfaces without the hindrance of traditional friction forces. The device’s innovative design allows it to maneuver seamlessly along surfaces while maintaining stability and speed that were previously unattainable with conventional mechanical transport systems. This leap in technology opens up exciting possibilities for fields that demand precise, rapid, and contactless manipulation of small components.

Traditional mechanical transport, such as conveyor belts, is crippled by frictional forces that decrease efficiency, impose speed limitations, and complicate precise positioning. As miniaturization progresses across mechanical, electronic, chemical, and biomedical domains, the need for refined transport mechanisms that can handle tiny parts becomes paramount. Addressing these challenges, the research team led by Associate Professor Ohmi Fuchiwaki has developed a levitation device driven by acoustic forces, enabling untethered movement free from cable restrictions, a significant hurdle in prior levitation efforts.

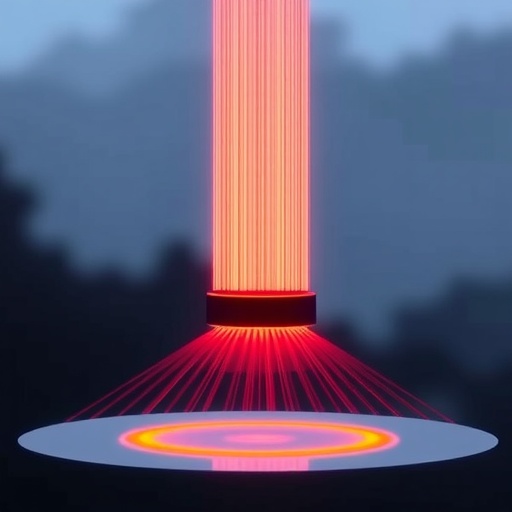

Acoustic levitation forms the core operating principle of the device, utilizing precisely controlled sound waves to generate a cushion of air that suspends the transport vehicle above the surface. Unlike diamagnetic or pneumatic levitation, which require bulky magnetic systems or pressurized gases, acoustic levitation offers a streamlined alternative without dependence on external apparatus, crucial for miniaturized and autonomous applications. Nevertheless, conventional acoustic levitation technologies are typically tethered by cables supplying power and control signals, which disrupt motion smoothness and positioning accuracy.

A major innovation introduced by this team is the realization of a wireless, untethered levitation system. Incorporation of a wireless drive circuit enables the device to sustain levitation height and execute rapid movement in all directions without mechanical connections. This autonomy significantly enhances the device’s agility and expands its potential for integration into robot systems or automated assembly environments where freedom of movement and reduced interference are critical factors.

One of the key engineering elements underlying the device’s frictionless movement is the deployment of a piezoelectric actuator. This actuator converts electrical energy into mechanical vibrations that generate a ‘squeeze film’ of air—a microscopically thin fluid layer trapped between the device and the surface. This squeeze film drastically reduces contact friction, allowing the device to glide effortlessly across various flat substrates. The ability to manipulate the thickness and stability of this squeeze film is essential to achieving consistent levitation and stable locomotion.

Experimental results convincingly demonstrate the device’s frictionless capabilities. The levitation device achieved speeds exceeding three meters per second on inclined surfaces, specifically maintaining free movement at angles up to 10 degrees. Intriguingly, when the levitation system was deactivated, the device failed to overcome gravitational pull on the same incline, underscoring the pivotal role of the levitative forces in overcoming frictional and gravitational barriers.

Load capacity tests further validate the device’s practical viability. While the system is optimized for lightweight operation, it can carry approximately 43 grams of payload in addition to its own weight totaling 150 grams without compromising levitation or mobility. Beyond this threshold, the levitation effect diminishes, and motion halts, indicating a current limitation but also a guideline for future improvements aimed at increasing load tolerance for broader industrial and biomedical applications.

The potential utilities of such a device are vast and promising. In industrial contexts, the ultrafast, frictionless transport system could revolutionize the assembly lines of microelectronics manufacturing where minute precision and speed are paramount. In biomedical fields, contactless delivery mechanisms using this technology could transport delicate cells or samples without risk of contamination or mechanical damage, elevating the standards for laboratory and clinical workflows.

The research team’s future vision involves integrating multiple levitation units into a cohesive robot design. By coordinating several devices and implementing a propulsion mechanism, they aim to realize complex, flexible robotic platforms capable of contactless manipulation and transport across irregular or complex surfaces. Such an innovation would mark a transformative development in automated manufacturing and medical device logistics.

While the device showcases remarkable performance on flat, inclined surfaces, ongoing efforts are directed toward improving levitation stability under variable loading conditions and enhancing performance on uneven terrains. Addressing these challenges will be critical to expanding the device’s applicability beyond controlled laboratory conditions toward real-world industrial or clinical environments where surface irregularities and complex load dynamics are typical.

This work, published in the July 2025 edition of Advanced Intelligent Systems, reflects a multidisciplinary collaboration among experts in mechanical and electrical engineering from YOKOHAMA National University and Aichi Institute of Technology. Their combined expertise in piezoelectric actuation, acoustic physics, and wireless control systems has culminated in this pioneering transportation technology.

The research also acknowledges considerable support from prestigious funding organizations including the Nakanishi Scholarship Foundation, the NSK Foundation for the Advancement of Mechatronics, and the Takahashi Industrial and Economic Research Foundation. Such financial backing underscores the global recognition of the project’s significance and opens pathways toward commercial development and broader scientific exploration.

In sum, YOKOHAMA National University’s development of an untethered, wireless, acoustic levitation device heralds a new era in frictionless transport and omnidirectional mobility. Through innovative use of piezoelectric squeeze films and wireless control, this technology promises substantial advancements in precision transport, mechanical assembly, and biomedical applications, ushering in a future where contactless manipulation at micro scales is both fast and reliable.

Subject of Research: Untethered levitation device enabling frictionless, omnidirectional transport

Article Title: Wireless Acoustic Levitation Device for Ultrafast, Contactless Omnidirectional Mobility

News Publication Date: July 10, 2025

Web References: https://doi.org/10.1002/aisy.202401098

Image Credits: YOKOHAMA National University

Keywords

Transportation, Friction, Spin manipulation, Electronics, Biomedical engineering