In the relentless pursuit of sustainable energy solutions, ammonia has emerged as a compelling hydrogen carrier, offering a carbon-free vector for clean fuel storage and transport. However, a persistent obstacle has been the sluggish kinetics of ammonia decomposition at industrially viable low temperatures, which throttles the efficient release of hydrogen. Breaking from convention, a team of chemical engineers has unveiled a pioneering approach that leverages extraordinarily high local temperatures generated within a novel reactor design, marking a transformative leap in ammonia decomposition technology.

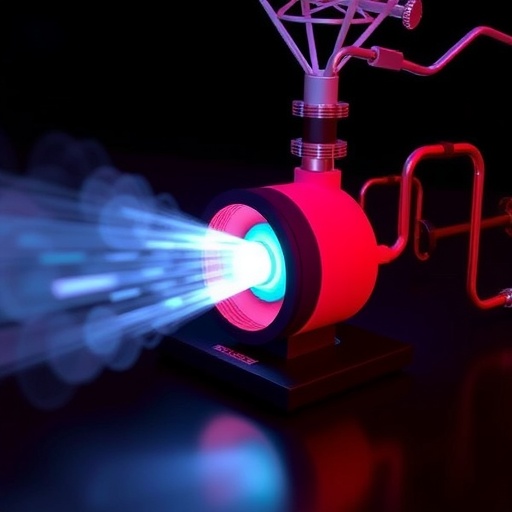

This cutting-edge system employs an electrified tungsten wire reminiscent of the classic incandescent lightbulb filament, but repurposed ingeniously to ignite rapid chemical transformations. By channeling electrical energy directly through this tungsten wire, the reactor achieves localized temperatures soaring to approximately 1,800 Kelvin. Such scorching thermal microenvironments catalyze the disintegration of ammonia molecules at unprecedented rates, dwarfing the performance of traditionally optimized catalytic surfaces under similar bulk conditions.

What sets this electrolytic lightbulb reactor apart is its intrinsically steep thermal gradient spanning the radial direction from the filament surface. The temperature plummets precipitously beyond the immediate vicinity of the wire, enabling the system to maintain ultra-high reaction rates without imposing a commensurate burden of energy input on the entire reactor volume. This effect translates into a remarkable enhancement in energy efficiency, circumventing the typical trade-off between high-temperature operation and power consumption that plagues conventional reactors.

Under optimized operational settings, this novel reactor configuration attains ammonia conversion rates climbing as high as 99.995%, an extraordinary figure that was historically difficult to achieve without subsequent complex gas separation processes. By delivering near-complete decomposition in situ, the system streamlines downstream hydrogen purification, simplifying the overall green hydrogen production pathway and lowering capital and operational expenditures.

The fundamental insight driving this technological breakthrough hinges on circumventing the kinetically limited regimes encountered in traditional catalytic reactors working at modest temperatures. The tungsten wire filament functions not only as a robust heating element but also as a direct microreactor platform where thermodynamics and reaction dynamics are finely balanced to facilitate ultrafast molecular cracking. This paradigm shift opens the door to ammonia decomposition processes that eschew costly noble metal catalysts yet offer performance metrics rivaling or exceeding them.

Moreover, the structural simplicity coupled with the intrinsic scalability of the tungsten wire lightbulb concept heralds a paradigm shift for on-site hydrogen generation. Conventional large-scale reactors tend to be bulky, costly, and energy-intensive, often presenting logistic and economic barriers for decentralized installations. In stark contrast, the proposed reactor can be engineered to be two to three orders of magnitude smaller in footprint without compromising throughput, offering a compelling modular solution suited for distributed green hydrogen infrastructures.

The research delves deeply into the thermal-fluidic interaction zones surrounding the electrically heated filament. The sharply decreasing radial temperature profile not only safeguards peripheral reactor components from heat damage but also reduces heat losses, further enhancing the system’s overall thermodynamic efficiency. This meticulous balance between intense local temperatures and cooler external conditions allows the process to operate with higher energy utilization factors rarely observed in high-temperature catalytic reactions.

Another remarkable feature of this approach is its inherent operational reliability given tungsten’s exceptional thermal and mechanical stability at elevated temperatures. Tungsten’s high melting point and resistance to oxidation under the controlled reactor environment bestow longevity and robustness to the lightbulb filament, enabling sustained ultrafast ammonia cracking over extended operational cycles. This durability may substantially reduce maintenance downtime and associated costs, which are critical parameters for industrial adoption.

Importantly, the reactor architecture fosters a clean reaction environment devoid of extraneous catalyst supports or binder materials that typically complicate synthesis and regeneration protocols. This elemental design minimizes potential contamination, catalyst sintering, and deactivation risks, facilitating a straightforward reactor construction and operation facile for scale-up.

The implications of this technology resonate across the emerging hydrogen economy landscape where the decarbonization of industrial sectors, transportation, and power systems depends critically on efficient hydrogen storage and release technologies. The integration of this electrified tungsten wire reactor into ammonia cracking units could sharply reduce the carbon footprint of green hydrogen production, accelerating the transition towards net-zero carbon energy portfolios.

From an engineering and process control vantage point, the ultrafast kinetics permitted by the localized high temperatures invite novel reactor operation strategies. The rapid attainment of chemical equilibrium ensures that the reactor can operate under transient or variable feedstock flows, potentially facilitating dynamic response capabilities essential for grid balancing and renewable energy storage applications.

Furthermore, this innovation may unlock pathways for coupling ammonia decomposition directly with hydrogen fuel cells or synthesis reactors in compact integrated modules, further compressing footprint and cost. It may also stimulate exploration of similarly electrified filament reactors for other challenging catalytic reactions where localized heating combined with drastic thermal gradients could orchestrate superior reaction kinetics.

Despite the breakthrough, scaling the tungsten wire lightbulb reactor to industrially relevant volumes will require meticulous engineering to manage electrical energy distribution, heat dissipation, and reaction product extraction. However, the intrinsic modularity and simplified design bode well for rapid development and commercialization.

As global energy sectors intensify their pursuit of carbon-neutral solutions, this technology introduces a novel, high-impact route to unleash hydrogen from ammonia rapidly, efficiently, and economically. This achievement could redefine the technical and economic landscape of hydrogen carriers and fuel supply chains, enhancing the feasibility of ammonia as a cornerstone fuel in the burgeoning green economy.

The research team’s novel electrified tungsten wire reactor exemplifies a disruptive approach that challenges established norms about catalysis and thermal management in chemical engineering, underscoring the power of innovative materials and reactor design to transcend limitations in energy conversion technologies.

In conclusion, the intersection of high-temperature electrification with sharp spatial thermal gradients embodied in the tungsten lightbulb reactor is poised to catalyze a revolution in ammonia decomposition and green hydrogen generation. This transformative platform not only promises ultrafast, highly efficient chemical processing but also sets the stage for decentralized, scalable, and economically viable clean energy systems vital for the sustainable future.

Subject of Research: Ammonia decomposition and green hydrogen production via high-temperature electrically heated tungsten wire reactors.

Article Title: Ultrafast ammonia decomposition using an electrified tungsten wire lightbulb reactor.

Article References:

Indriadi, K.S., Wong, S.S., Han, P. et al. Ultrafast ammonia decomposition using an electrified tungsten wire lightbulb reactor. Nat Chem Eng (2025). https://doi.org/10.1038/s44286-025-00283-x

Image Credits: AI Generated