In the realm of advanced manufacturing, a groundbreaking innovation emerges from the halls of ETH Zurich, spearheaded by a team of dedicated undergraduate students. These aspiring engineers, under the mentorship of esteemed professors, have rolled out a high-speed multi-material metal 3D printer, a piece of technology that could reshape how metal components for aerospace and other industries are produced. The printer operates on a unique principle of laser power bed fusion, which allows for the simultaneous deposition and fusion of multiple materials, thus drastically improving efficiency and production outputs.

This revolutionary machine arose from the pressing challenges posed by the Swiss Academic Space Initiative, ARIS, which is ambitiously crafting its own rocketry with the goal of breaching the Kármán Line—an altitude of 100 kilometers that marks the boundary of space. The nascent engineers played a pivotal role in developing rocket nozzles that utilize bi-liquid fuels, which requires materials capable of withstanding extreme conditions during launches. Traditionally, creating such multi-metal components has been an arduous and expensive process, often beyond the reach of smaller teams and academic laboratories.

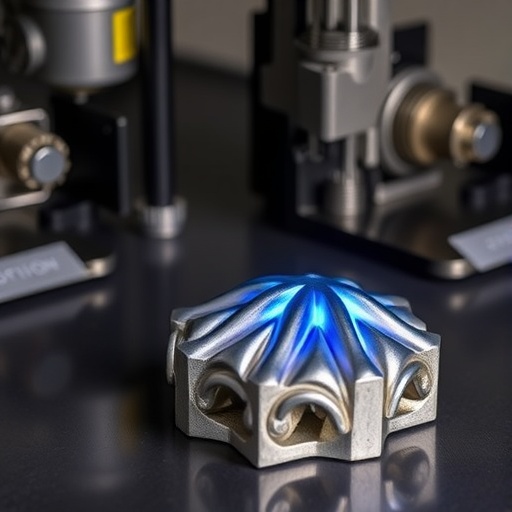

The new printer incorporates a sophisticated rotating platform, which stands in stark contrast to conventional additive manufacturing methods. Traditional printers require a complete halt in processes to lay down new layers of powder after each segment of fusion. In contrast, the ETH Zurich innovation enables concurrent operations where powder material is deposited and fused instantaneously, significantly accelerating the overall production timeline and reducing waste. Indeed, this method can realize cylindrical components two-thirds faster compared to existing technologies, paving the way for unprecedented manufacturing capabilities.

Central to this printer’s design is its ability to leverage two different metals in a single manufacturing run. Traditional metal printing techniques often entail a lengthy series of multi-step processes with substantial waste material generated from leftover metal powder. The ETH team’s machine cleverly applies materials only where they are necessary, eliminating excess and inefficiency. This feature is crucial, particularly in competitive fields like aerospace where precision and resource management are paramount.

Among the technical challenges faced by students during the development of this innovative machine was the intricate synchronization of the scanning laser with the movements of both the gas supply and powder deposition systems. Given the unique requirements for this cutting-edge technology, many parts were designed and fabricated from scratch by the team. The ingenuity displayed in creating these bespoke components has resulted in a machine that is not just experimental but appears ready for industrial application.

Quality assurance is another critical aspect of this new printing technology. The printer has been designed with a sophisticated gas flow mechanism that ensures an inert atmosphere around the material being fused, thus preventing oxidation and other unwanted reactions. By meticulously managing the local conditions during printing, the overall quality of the final products can be significantly enhanced, addressing one of the foremost challenges in metal additive manufacturing.

This innovation is poised to open doors not only for ARIS and the broader aerospace sectors but also for various other fields where precision-engineered components are required. Applications could extend to the production of gas turbines, electric motors, and components in aircraft manufacturing, demonstrating the versatility of this new technology. A patent application has already been filed by the team at ETH Zurich to protect this unique rotary multi-material laser powder bed fusion technology, which stands to have substantial commercial implications.

As the project evolves, the team is actively seeking industrial partners to collaborate on further development and scaling opportunities. They anticipate that future iterations of this technology could handle larger components and higher printing speeds, further solidifying its role in modern manufacturing. The ambitious vision of leveraging advanced 3D printing technologies is catalyzing a sea change in engineering practices, particularly in high-stakes industries like aerospace that demand excellence.

Currently, the prototype can manufacture components with diameters of up to twenty centimeters, which showcases the machine’s initial capabilities. The cutting-edge research from ETH Zurich emphasizes not only the excitement of innovation from academia but also the potential that such initiatives have to impact real-world applications significantly. This intersection of education and industrial application serves as a poignant reminder of the power of collaboration and creativity in solving complex engineering challenges.

What makes this achievement even more remarkable is the time frame within which it was completed. In just nine months, a collaborative team of six undergraduate students developed, built, and tested a functioning 3D printer that has the potential to advance manufacturing processes considerably. This initiative highlights the promising talent nurtured in academic settings and the vital role that young engineers can play in shaping the future of technology.

As the world continues to push the envelope of innovation, the advancements made in 3D printing by the ETH Zurich students represent a significant leap forward. The implications of such technology extend beyond just aerospace; they herald a new chapter in manufacturing, focused on efficiency, effectiveness, and sustainability. The journey from concept to practical application illustrates the importance of dedication, collaboration, and institutional support in driving transformative ideas to fruition.

In conclusion, the inception of this high-speed multi-material 3D printer is a testament to the innovative spirit of young researchers, showcasing how education can drive technological progress. As industries gravitate towards more sustainable and efficient manufacturing solutions, developments like these will be crucial in addressing future challenges and unlocking new possibilities across various sectors.

Subject of Research: Development of a high-speed multi-material metal 3D printer

Article Title: Design and analyses of powder deposition, gas flow, and productivity for a rotary laser powder bed fusion system

News Publication Date: 6-Jun-2025

Web References: CIRP Annals

References: Bambach M, Tucker MR: Design and analyses of powder deposition, gas flow, and productivity for a rotary laser powder bed fusion system. CIRP Annals – Manufacturing Technology, 2025. doi: 10.1016/j.cirp.2025.04.005

Image Credits: Michael Tucker / ETH Zurich

Keywords

3D Printing, Additive Manufacturing, Aerospace Engineering, Metal Components, ETH Zurich, Rotary Technology