Physicists at the University of Liège have unveiled a groundbreaking technique that allows them to sculpt the surface of water by harnessing surface tension in an unprecedented way. Through innovative use of 3D printing technology, researchers have engineered arrays of tiny spines that interact with the liquid interface to create predetermined liquid landscapes. This breakthrough holds significant promise for the fields of microscopic transport, particle sorting, and even environmental remediation applications such as the control of marine pollution.

At its core, this technology exploits the meniscus—the subtle curvature formed at the edge of a liquid due to intermolecular forces known as capillarity. Typically, the surface of a liquid remains flat under gravity, and any small variation, like the meniscus, is limited to millimeter scales at container edges. However, the team at the GRASP laboratory at the University of Liège, collaborating with scientists from Brown University, has demonstrated that by printing densely packed conical spines onto a substrate, these individual menisci can overlay and combine to form extended liquid reliefs with rich and programmable topographies.

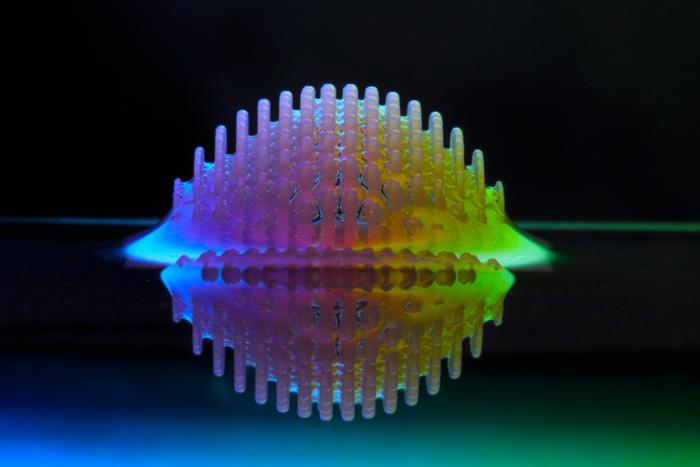

The science behind this innovation draws upon a deep understanding of surface tension-driven phenomena at liquid interfaces. Each 3D-printed spine induces a localized meniscus deformation. When arrays of these spines are spaced with precision, their respective menisci superpose, resulting in a macroscopically visible, “giant” meniscus that sculpts the water surface into slopes, valleys, and even complex geometrical shapes. Such topographies can be precisely controlled by altering parameters such as spine height, spacing, and arrangement, enabling a vast design space for liquid shaping.

This advance effectively turns the liquid surface into a programmable landscape, which the researchers have illustrated by creating a miniature fluid replica of the Atomium monument in Brussels. This demonstration exemplifies not just an artistic feat, but a fundamental shift in our ability to manipulate fluid interfaces via micro-scale engineering, moving beyond static, flat liquid surfaces to dynamic and structured liquid geometries.

One of the most intriguing applications of this platform is its capability to direct the motion of floating particles solely through gravity-driven interaction with these liquid slopes. Lighter objects, due to buoyancy forces, tend to ascend along inclined liquid surfaces, whereas denser particles naturally descend as they slide “downhill” on these micro-engineered menisci. This passive sorting mechanism leverages fundamental principles such as Archimedes’ buoyant force and gravity, without the need for external fields or active pumps.

Such controlled manipulation of microparticles opens exciting avenues in micromanipulation and microfluidic technologies. Potential applications range from sorting microplastics and oil droplets from contaminated water to precise positioning of droplets or particles in lab-on-a-chip devices. The simplicity and energy efficiency of this method—requiring no mechanical actuators or electric fields—stand out as substantial advantages in practical contexts.

Looking further into the future, the research envisions dynamic control of these liquid topographies by utilizing responsive materials for the spines. Materials capable of deformation in response to magnetic fields or other stimuli could enable real-time reshaping of the liquid landscape. Such developments would substantially broaden the scope of applications, allowing scientists and engineers to adapt fluid surfaces on-the-fly in response to environmental cues or operational demands.

From a methodological standpoint, the team’s use of high-resolution 3D printing technology was critical in realizing these precision-founded liquid landscapes. The ability to produce spines with meticulously defined geometries and spacing ensured the repeatability and predictability of meniscus formation and overlap. This level of control is essential when designing complex liquid topographies as it directly correlates to the curvature, slope, and overall shape of the induced landscape.

The interplay between capillary forces and gravity at the heart of this research is a remarkable example of physics principles applied creatively to shape fluid behavior at scales relevant for both fundamental inquiry and technological innovation. Menisci, often considered a trivial and unavoidable artefact in liquid container systems, are here harnessed as active tools to program liquid surfaces. This flips conventional understanding and opens new possibilities for fluid interface design.

Moreover, the research highlights why the meniscus has been underappreciated in fluid dynamics applications. Traditionally viewed merely as a boundary phenomenon, these liquid interface deformations are now demonstrated as scalable and programmable when combined strategically. This conceptual upgrade widens the frontier for investigating how liquids can be structured without mechanical barriers, paving the way for new microfluidic devices that use liquid topographies as functional components.

To summarize, the collaborative work pioneered by the University of Liège and Brown University researchers marks a significant leap in liquid interface control. By combining physics insights with cutting-edge 3D printing techniques, they have created a flexible platform capable of sculpting water surfaces into complex, predesigned shapes. This platform’s potential impact spans fundamental science to practical environmental and industrial technologies.

As the technique matures and integration with smart responsive materials becomes feasible, programmable liquid topographies may revolutionize the fields of particle manipulation and microfluidics. These capabilities could lead to novel sorting devices, environmental purification tools, and even bioengineering applications where the gentle and precise control of microscopic agents is paramount. The future holds promise for leveraging the physics of liquid interfaces in unprecedented ways, transforming fluid surfaces into functional and adaptable landscapes.

Subject of Research:

Physicists exploiting surface tension and meniscus deformation through 3D-printed microstructures to program liquid surface shapes.

Article Title:

3D-printed spines for programmable liquid topographies and micromanipulation

News Publication Date:

10-May-2025

Web References:

http://dx.doi.org/10.1038/s41467-025-59483-x

Image Credits:

Université de Liège / M.Delens

Keywords:

Surface tension, meniscus, capillarity, 3D printing, liquid topography, micromanipulation, microfluidics, particle sorting, programmable liquid surfaces, microplastics removal, fluid interface engineering, responsive materials