In the relentless quest for sustainable energy solutions and the efficient extraction of critical minerals, lithium has surged to the forefront as a vital component powering the global green transition. The challenge, however, lies not only in lithium’s growing demand but also in the sustainable and scalable technologies required for its extraction. A recent breakthrough, described in an innovative study published in Nature Communications, reveals a meticulously designed thin film nanocomposite cation exchange membrane that promises to revolutionize lithium extraction with unprecedented precision and efficiency.

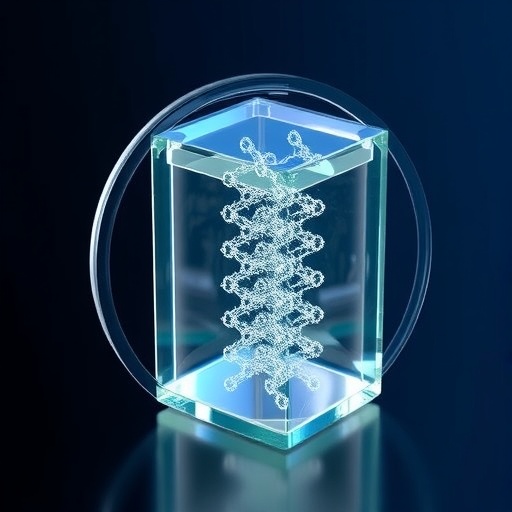

At the heart of this advancement is the rational design of a thin film nanocomposite (TFN) membrane, engineered explicitly for selective lithium recovery. Traditional methods of lithium extraction often grapple with issues such as low selectivity, membrane fouling, and scalability problems. By leveraging cutting-edge nanomaterials and polymer science, the researchers have synthesized a membrane that delicately balances ionic transport, mechanical robustness, and chemical resilience. This novel membrane’s architecture integrates nanoscale fillers within an ion exchange matrix, facilitating enhanced ion separation while maintaining high flux rates essential for industrial-level operations.

The synthesis approach detailed in the research is both elegant and scalable, a critical factor in translating laboratory success into real-world application. By incorporating nanomaterials such as layered double hydroxides or metal-organic frameworks, the composite membrane achieves enhanced selectivity through size-exclusion effects and electrostatic interactions. These properties are meticulously tuned to discriminate lithium ions from competing cations like sodium, magnesium, and calcium, which abound in natural brines and recycling streams. Such precision in ion selectivity is pivotal in minimizing the energy footprint of lithium extraction processes.

One of the most remarkable features of this TFN membrane is its ability to maintain high permeability while significantly elevating selectivity. This alleviates the traditional trade-off faced in membrane technologies, where increasing selectivity usually means sacrificing throughput. The nanocomposite structure endows the membrane with robust ion channels that facilitate rapid lithium ion transport while impeding larger or multivalent ions. Consequently, this ensures that lithium extraction is both energy-efficient and economically viable, even when processing brines with complex ionic compositions.

Understanding the membrane’s ion transport mechanisms involved sophisticated physicochemical characterization techniques. Through atomistic simulations, electron microscopy, and spectroscopic analysis, the researchers uncovered how nanoscale modifiers create preferential pathways and localized charge environments. These pathways selectively accelerate lithium ion movement, providing a mechanistic basis for the membrane’s superior performance. This fundamental insight not only validates the membrane’s design principles but also opens avenues for further refinement and application-specific customization.

Sustainability considerations are paramount in this innovation. The membrane’s scalable fabrication process employs environmentally benign solvents and polymers, aligning with green chemistry principles. Its operational stability across various pH ranges and ionic strengths underscores its practical durability for diverse lithium sources, from hard rock ores to geothermal brines. Moreover, its resistance to fouling and chemical degradation ensures longer membrane lifespans, reducing maintenance costs and environmental waste associated with membrane replacement.

From an industrial perspective, this development could dramatically impact lithium supply chains. Current lithium extraction methods, such as evaporation ponds or solvent extraction, are often slow, resource-intensive, and environmentally detrimental. By contrast, the TFN membrane technology streamlines the extraction process, potentially lowering operational costs and reducing greenhouse gas emissions tied to lithium procurement. This offers an enticing prospect for energy and battery manufacturers seeking sustainable material sourcing in an increasingly competitive market.

In addition to extraction from natural resources, the membrane’s high selectivity suggests promising applications in lithium recycling efforts. As the demand for lithium-ion batteries surges, end-of-life battery materials become a rich but challenging feedstock. The unique membrane could facilitate targeted lithium recovery from recycled battery leachates, contributing significantly to circular economy initiatives and reducing dependence on virgin lithium sources.

The research team also demonstrated the membrane’s scalability by fabricating large-area samples that retained performance consistency, a notable achievement seldom reported in early-stage membrane studies. This validates the technology’s readiness for pilot-scale testing and eventual industrial deployment. Furthermore, the membrane exhibited excellent mechanical flexibility and resistance to pressure variations, critical parameters for integration into commercial lithium extraction units.

Economic modeling within the study suggests that adopting this membrane technology could reduce lithium extraction costs by up to 30% compared to conventional methods. When extrapolated to global lithium production scales, such cost savings could accelerate the adoption of electric vehicles and renewable energy storage by bringing down battery prices. It also positions this technology as a facilitator in achieving net-zero emission targets by ensuring critical battery materials remain abundant and ecologically sourced.

Looking ahead, the researchers envision extending this membrane platform to other strategic metal separations, including cobalt, nickel, and rare earth elements, each integral to the clean energy transition. The modularity of the nanocomposite design allows fine-tuning of ion exchange moieties and nanoparticle fillers to target different ions selectively. This adaptability underscores the broader significance of this work in the field of membrane science and resource recovery.

Collaboration with industry stakeholders is already underway, aiming to integrate this membrane into existing lithium extraction plants and recycling facilities. Pilot projects are planned to evaluate long-term operational stability, fouling resistance in real-world brines, and economic feasibility under varying market conditions. These translational steps are crucial for underpinning the technology’s impact beyond laboratory success.

This breakthrough exemplifies the transformative potential of nanotechnology-driven materials science in addressing pressing environmental challenges. By optimizing the interface between nanoscale structure and macroscopic functionality, the research pioneers a path toward more sustainable and efficient resource extraction methodologies. It also highlights the critical role interdisciplinary approaches play in solving complex global supply chain issues tied to climate action.

In summary, this thin film nanocomposite cation exchange membrane marks a groundbreaking advancement in lithium extraction technology. Its combination of scalability, selectivity, and operational resilience presents a compelling alternative to current methodologies, with the potential to redefine lithium sourcing paradigms. As the green energy economy continues to expand, innovations like this will be instrumental in ensuring critical raw materials are obtained responsibly, efficiently, and sustainably.

Subject of Research: Advanced membrane technology for selective lithium ion extraction in sustainable energy applications.

Article Title: A rationally designed scalable thin film nanocomposite cation exchange membrane for precise lithium extraction.

Article References:

Feng, Y., Zhu, Y., Chen, W. et al. A rationally designed scalable thin film nanocomposite cation exchange membrane for precise lithium extraction. Nat Commun 16, 8618 (2025). https://doi.org/10.1038/s41467-025-63660-3

Image Credits: AI Generated