In the rapidly evolving realm of additive manufacturing, predicting the lifespan and quality of 3D-printed metal components remains one of the most significant challenges facing engineers and industry leaders alike. Traditionally, supercomputers have been tasked with the painstaking evaluation of these parts, requiring upwards of 18 months to analyze a single component’s structural integrity and forecast its failure timeline. This extensive time frame not only delays deployment but also impedes the broader adoption of 3D printing technologies in critical defense and industrial applications. Addressing this bottleneck, the Defense Advanced Research Projects Agency (DARPA) has initiated the Structures Uniquely Resolved to Guarantee Endurance (SURGE) program, which mandates a revolutionary compression of evaluation periods—from months down to mere days—and a simplification of the computational process so it can be executed on accessible platforms like laptop computers.

Responding to this formidable call to action, a team of four distinguished faculty members from Texas A&M University has embarked on a groundbreaking journey to reshape the additive manufacturing landscape. With a generous grant totaling $1.6 million from DARPA, this interdisciplinary group is developing an integrated system designed to accelerate the determination of 3D-printed part quality and durability. This initiative promises not only to fast-track manufacturing timelines but also to amplify the reliability of components intended for military applications, thus reinforcing national defense capabilities. The implications of this research extend beyond the military, potentially triggering a paradigm shift throughout the entire additive manufacturing ecosystem.

What sets this project apart is its holistic approach to an inherently complex problem. Traditional evaluations hinge heavily on the specifics of the production machinery and methods used, but 3D-printed parts introduce a new level of complexity; each piece bears a distinct microstructural "fingerprint," created by unique signatures of microscopic features and defects. These subtle variations occur even among parts fabricated on the same machine using identical raw materials. Such defects—unavoidable with current technology—play a decisive role in determining the component’s durability and failure progression, making conventional certification methods inadequate.

The current certification process for these metal components is notoriously time-consuming and costly, representing a significant hurdle towards the widespread implementation of additive manufacturing. The Texas A&M team’s approach aims to revolutionize this process by integrating real-time data acquisition with microstructural characterization to drastically reduce evaluation time and cost. Dr. Mosen Taheri Andani, an assistant professor of mechanical engineering and a core member of the research team, emphasizes the project’s ambition: “By integrating in-situ data with the underlying microstructural features formed during printing, the program will bridge expertise in process monitoring, microstructure characterization, and property evaluation—paving the way for faster, more reliable deployment of additive-manufactured parts.”

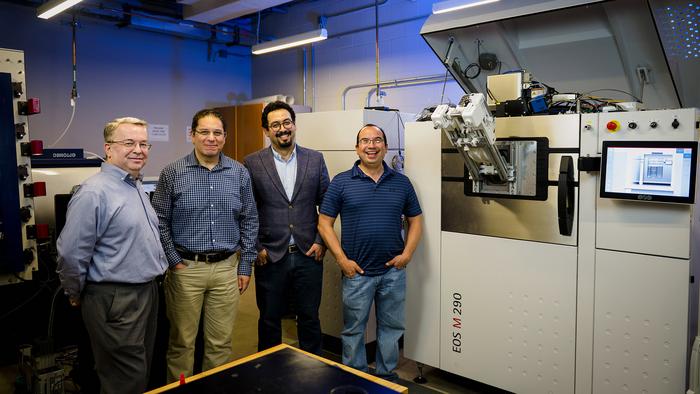

The team comprises experts across materials science, industrial and systems engineering, and mechanical engineering to tackle the multidimensional aspects of this challenge. Alongside Dr. Taheri Andani are Dr. Raymundo Arróyave, Chevron Professor (II) of materials science and engineering; Dr. Aala Elwany, professor of industrial and systems engineering; and Dr. Ibrahim Karaman, Chevron Professor and head of the department of materials science and engineering. Their combined expertise ensures that the project benefits from comprehensive perspectives spanning microstructural analysis, process dynamics, and industrial process optimization. Drs. Taheri Andani and Elwany both hold affiliations within materials science and engineering, reinforcing the project’s interdisciplinary core.

A pivotal shift in the project’s methodology lies in reconceptualizing how additive manufacturing parts are evaluated. Instead of relying on the notion that parts produced in similar conditions have consistent properties, the team challenges this assumption by acknowledging the distinct microstructural defects embedded within each component during the printing process. These defects manifest as variations in size, distribution, and location, which critically influence the mechanical properties and fatigue life of the parts. Harnessing this understanding allows for a more tailored and precise prediction of part endurance, moving away from one-size-fits-all certification models.

Financial and technical support from DARPA is part of a larger strategic collaboration involving six partners, including the University of Michigan, Auburn University, the University of California at San Diego, ASTM International, and industry pioneers Addiguru and AlphaStar. This consortium embodies the convergence of academia, standard-setting organizations, and industrial stakeholders working in unison to catalyze innovation in additive manufacturing. The project’s four-year timeline is punctuated by intensive phases of sensor development, data integration, and algorithm refinement, all aimed at translating raw sensor signals into actionable insights on part quality and lifespan.

The initial phase of the Texas A&M team’s role focuses on co-developing a sophisticated sensor suite with Addiguru, designed to be embedded into commercial additive manufacturing platforms. This package will capture multidimensional, heterogeneous data streams during the printing process, ranging from thermal signatures and acoustic emissions to real-time imaging. Achieving such high-fidelity monitoring is essential to detecting the formation and evolution of microstructural defects as the metal layers solidify. Once this sensing technology matures, the team will embark on constructing an artificial intelligence-powered defect detection system, capable of interpreting the multidimensional data to predict where and how defects materialize.

Simultaneously, Texas A&M will synergize efforts with collaborators like the University of Michigan and AlphaStar to develop predictive models that can forecast microstructural features based on sensed process data. ASTM International’s involvement ensures that findings will be integrated into industry-wide standards, facilitating the adoption of accelerated certification protocols across manufacturing sectors. This collaborative structure ensures that the research transcends laboratory confines and is adequately positioned for real-world deployment.

Dr. Ibrahim Karaman notes, “This DARPA project is particularly exciting for us because it represents a unique opportunity to address one of the most critical challenges facing the field today. We are confident that this work will have a transformative impact on industry and help unlock the full potential of additive manufacturing at scale.” His optimism reflects the broader sentiment in the engineering community, where breakthroughs in rapid, reliable part qualification will unleash unprecedented capabilities—from agile military logistics to manufacturing flexibility in commercial sectors.

Underpinning this initiative is the principle that speed and accuracy must coexist. Accelerating qualification times cannot come at the expense of reliability—a balance that requires sophisticated data fusion, advanced modeling, and rigorous validation. The fusion of sensor data with AI-driven analytics combined with nuanced understanding of process-microstructure-property relationships represents the cutting edge of additive manufacturing research.

Funding and administrative oversight from the Texas A&M Engineering Experiment Station (TEES) further exemplify the university’s commitment to positioning itself as a leader in this transformative field. Through such institutional backing, the research is well-equipped to harness the extensive resources necessary for pushing the boundaries of materials science, mechanical engineering, and industrial process innovation.

As this ambitious program gains momentum, its ripple effects promise to revolutionize how complex metallic parts are produced, evaluated, and deployed across military and industrial frontiers. The accelerated certification process will enable rapid integration of 3D printing in applications where failure is not an option, ultimately reshaping supply chains and manufacturing landscapes. By pioneering new paradigms in process sensing, AI-driven analytics, and microstructural prediction, the Texas A&M research team is charting a new course toward a future where 3D-printed components are as reliable as traditionally forged parts—but accessible on unprecedented timescales.

Subject of Research: Additive manufacturing, rapid qualification and lifespan prediction of 3D-printed metal components

Article Title: DARPA Funds Texas A&M to Revolutionize Rapid Certification of 3D-Printed Metal Parts for Defense Applications

Image Credits: Leon Contreras/Texas A&M Engineering

Keywords: Fabrication; Additive manufacturing; Materials engineering; Mechanical engineering; Mechanical components; Manufacturing equipment; Machine design; Industrial engineering; Industrial production; Manufacturing; Business; Manufacturing industry