Researchers from Seoul National University have introduced an innovative thermal management technology that enables selective heating and cooling functions using just one material and one process, altogether negating the need for electrical power. Led by Professor Seung Hwan Ko of the Department of Mechanical Engineering, this breakthrough emerges as a transformative solution to overcome the limitations of existing thermal management technologies, often burdened by complexity and energy consumption.

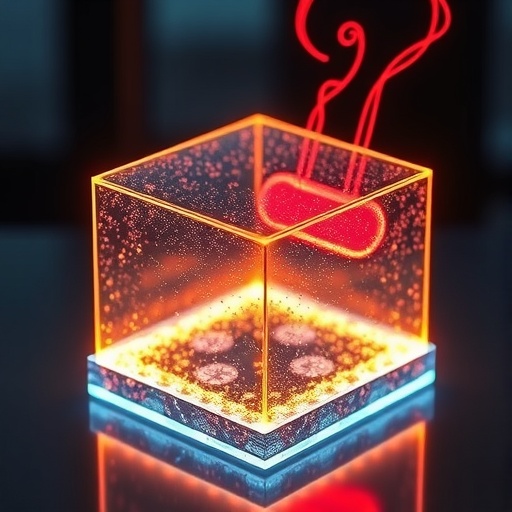

The novel approach hinges on the manipulation of a transparent silicone polymer known as PDMS (Polydimethylsiloxane), processed with laser output intensity adjustments. When exposed to high-intensity laser light, the polymer’s surface transitions into a white porous structure that reflects solar radiation and emits thermal energy, thus generating cooling effects conducive to maintaining lower temperatures in hot outdoor environments. On the other hand, applying a low-intensity laser causes the formation of a black porous structure that serves the opposite function, primarily absorbing sunlight to produce heat.

This dual-functionality not only simplifies the complexity typically associated with conventional thermal management methodologies, which often require different materials and multifaceted processing to achieve the same ends, but it also suggests a new pathway towards zero-energy thermal solutions. Given the pressing realities of climate change and energy crises, the need for sustainable methods to manage temperature without additional electrical drain has never been more critical. The developed technology promises to create just such solutions—enabling environments to remain dramatically cooler during scorching summer months and warmly insulated during frigid winters.

The implications of this research extend well beyond merely regulating ambient temperatures. The team rigorously tested their novel material’s capabilities in real-world environments. Under the glaring sun, the cooling surface achieved an average temperature of 5.89 degrees Celsius lower than the surrounding environment, while the heating surface heated itself to 58.1 degrees Celsius. Such remarkable thermal regulation demonstrates not only the practicality but the outstanding performance of their novel thermal management solution.

Further simulations indicate promising potential for economic savings in energy costs should this thermal management technology be implemented in building construction. The simulations projected a staggering annual reduction of up to 26.5% in heating and cooling energy expenses when incorporating this innovative material into rooftops. This not only illustrates potential initial investment returns but also underscores the technology’s promise to contribute significantly to energy efficiency and sustainability in architectural designs.

Additionally, the incorporation of this technology may expand into ‘plus-energy’ applications. By harnessing the temperature gradient formed between the surfaces – one cooling and the other heating – researchers envision creating solar-driven thermoelectric generators capable of producing electricity from thermal differences. Such advancements could aid in meeting energy demands while simultaneously reducing reliance on traditional electrical grids.

The research’s significance is compounded by its potential applications in various sectors, from building energy efficiency to outdoor equipment thermal stability and renewable energy generation—even extending into sophisticated systems such as solar-assisted desalination processes. As a result of the simplicity and cost-effectiveness of the technology, it holds vast promise for widespread implementation across diverse fields that seek to reduce their carbon footprints.

Professor Seung Hwan Ko emphasized the groundbreaking nature of this technology in redefining thermal management strategies. The ability to seamlessly flip between heating and cooling functions using a standardized material and a singular laser process drives forward the discourse around innovative manufacturing and material science. He stated that this approach opens the door for multiple real-world applications across various industrial sectors, fundamentally altering how we perceive and manage thermal energy.

Lastly, this work underlines the urgency of adapting our technologies and communities for an environmentally sustainable future. With energy usage on the rise and the atmosphere under increasing stress from climate change, innovations such as the one spearheaded by the research team at Seoul National University could represent the kind of paradigm shift that society needs to transition towards a more energy-efficient and ecologically friendly existence.

As the world grapples with both an energy crisis and the escalating consequences of climate change, the emergence of such technologies becomes not just beneficial but essential. At a time when every degree matters in temperature regulation, the implications of this revolutionary technology could represent a quantum leap forward, one that bolsters sustainability while meeting contemporary energy demands. The path forward is illuminated with hope, as this single-material solution sets the stage for the future of energy management.

Subject of Research: Not applicable

Article Title: Monolithic Integration of Radiative Cooling and Solar Heating Functionalities by Laser-induced Pyrolysis

News Publication Date: 20-Aug-2025

Web References: 10.1016/j.joule.2025.102007

References:

Image Credits: © Joule, originally published in Joule

Keywords: Thermal management technology, cooling and heating functions, laser processing, energy efficiency, sustainability, climatic adaptation, polydimethylsiloxane (PDMS), renewable energy, zero-energy technology.