In a groundbreaking advancement in the field of biotransformations, a team of researchers from Beijing Forestry University has unveiled an innovative enzyme immobilization system utilizing bamboo-based cellulose nanofibers. This newly developed microreactor system promises to revolutionize the efficiency and sustainability of biotransformation processes by harnessing the unique properties of bamboo, a resource that is both abundant and renewable. Such advancements are essential in various applications, ranging from pharmaceuticals to food processing, where efficiency and environmental sustainability are increasingly demanded.

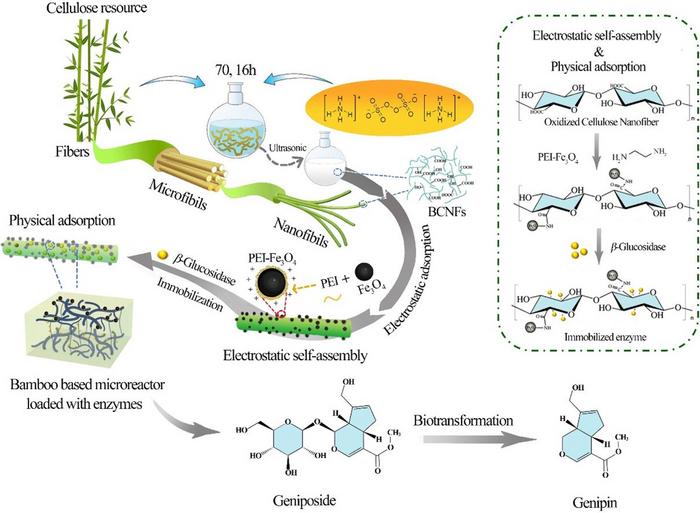

The research is spearheaded by Dr. Yujie Fu and Dr. Jie Yang, who have meticulously crafted a system that employs carboxylated bamboo-based cellulose nanofibers (BCNFs). The preparation of these nanofibers involved an intricate oxidation procedure using ammonium persulfate, which was followed by chemical modification with polyethyleneimine (PEI) and the integration of magnetic nanoparticles (Fe3O4). This multi-step approach ensures enhanced enzyme loading capacity and stability, which are critical factors for maintaining high enzymatic activity during the biotransformation processes.

The complex interactions facilitated by the BCNFs in the microreactor lead to highly efficient conversions, as typified by the researchers’ successful transformation of geniposide into genipin, a compound that holds promise for applications in both the pharmaceutical and food industries due to its bioactive properties. The efficiency of this microreactor system is evident, with a remarkable transformation rate of 93.10% achieved during the experiments. Such high conversion rates are hard to attain with conventional methods, which often struggle with enzyme immobilization and activity retention.

Another noteworthy aspect of this innovative system is its impressive thermal stability and reusability. The researchers reported that these immobilized enzymes maintained a striking 76.47% of their initial activity even after undergoing five continuous cycles of use within the microreactor framework. This characteristic not only demonstrates the resilience of the bamboo nanofibers as a support medium but also highlights the potential for sustained operations in practical applications, leading to reduced costs and waste.

The research findings underscore the pivotal role that bamboo, traditionally viewed as merely a construction material or source of fiber, can play in transformative biotechnological applications. The versatility of bamboo stems from its unique composition, which inherently supports the needs of immobilization technologies. By tapping into this underutilized resource, the researchers are not only paving the way for groundbreaking biotransformation methodologies but also promoting an eco-friendly approach that aligns with contemporary sustainability goals.

Through experimental studies, the research team has meticulously documented the benefits of their microreactor system. The detailed characterization of the bamboo-based nanofibers, alongside the evaluation of enzymatic activity under varying conditions, offers substantial insights into the operational parameters that influence the effectiveness of biotransformations. By varying the concentration of the immobilized enzymes or adjusting the reaction temperatures, researchers managed to optimize the conditions further, leading to enhanced efficiency and productivity in generating desired biochemical compounds.

Additionally, the implications of such advancements extend beyond mere academic value. The potential industrial applications of this bamboo-based microreactor system are vast. Industries that rely on enzymatic reactions for the production of flavors, fragrances, and health-promoting compounds will undoubtedly benefit from characteristics such as improved efficiency, cost-effectiveness, and lower environmental impact offered by this innovative technology.

Moreover, as the world pivots toward sustainable industrial practices, the adaptation of renewable materials like bamboo in scientific research is gaining heightened attention. This research embodies a fusion of traditional resource utilization and modern technological advancements, representing a pivotal shift in the way we perceive waste and sustainability within biocatalytic processes.

The research team envisions a future where their findings can lead to large-scale applications. With additional studies aimed at refining the integration of bamboo-based nanofibers in various enzyme systems, there is palpable excitement surrounding the next steps. These may include the exploration of different enzymes alongside bamboo nanofibers, the assessment of factory setups to ascertain industrial feasibility, and collaborations with industries eager to adopt greener technologies.

In conclusion, the breakthrough achieved by Dr. Fu, Dr. Yang, and their team holds considerable promise for transforming biotransformation processes. With a renewed perspective on bamboo as a strategic resource for the biotechnology industry, this research is expected to inspire further innovation and exploration in the field. The ongoing pursuit of efficiency, sustainability, and environmental consciousness is crucial as industries worldwide navigate the complex landscape of modern production demands.

The implications of this work exemplify how traditional materials can be repurposed to align with high-tech applications in biotechnology. As these researchers continue to break ground and set the stage for next-generation bioprocesses, the integration of bamboo into enzymatic applications is poised to become a hallmark of future advancements in the field.

In summary, this study serves as a compelling testament to the innovative synergy between traditional resources and modern science, ushering in a new era of enzymatic applications that are not only effective but also eco-friendly.

Subject of Research: Enzyme immobilization using bamboo-based cellulose nanofibers

Article Title: Immobilized Enzyme Microreactor System with Bamboo-Based Cellulose Nanofibers for Efficient Biotransformation of Phytochemicals

News Publication Date: 28-Mar-2025

Web References: Journal of Bioresources and Bioproducts

References: DOI

Image Credits: Credit: State Key Laboratory of Efficient Production of Forest Resources, Beijing Forestry University, Beijing, China

Keywords: Bamboo, Enzyme immobilization, Biotransformation, Nanofibers, Sustainable practices, Biotechnology, Eco-friendly technology, Renewable resources, Bioactive compounds, Thermal stability, Reusability, Experimental study.