In a groundbreaking advancement for the future of display technology, a research team led by Professor Tae-Woo Lee from Seoul National University and SN Display Co., Ltd. has unveiled a novel synthesis technique that marks a decisive step toward the industrial-scale production of ultra-high color purity perovskite nanocrystals (PeNCs). These nanocrystals are poised to revolutionize the next generation of visual displays, delivering unprecedented color accuracy and efficiency without the constraints imposed by traditional high-temperature or vacuum-based manufacturing processes. Published in the prestigious journal Nature on February 18, 2026, this work heralds a new era in emissive materials, showcasing a method that maintains near-perfect photoluminescence quantum yield (PLQY) when scaled from laboratory milliliter quantities to production-scale reactors.

The contemporary display market is increasingly driven by the demand for immersive visual experiences that replicate the captivating vividness and nuance perceived by the human eye. Achieving such realism necessitates displays that conform to the Rec. 2020 color gamut, a rigorous standard demanding about a 40% wider color range than the currently dominant DCI-P3 standard. Traditional emissive materials such as organic emitters and quantum dots suffer from relatively broad emission bandwidths, characterized by full width at half maximum (FWHM) values hovering around 50 nm and 30 nm, respectively. These spectral limitations impose fundamental barriers to satisfying the stringent color purity criteria essential for cutting-edge applications like Ultra High Definition (UHD) televisions, augmented reality (AR), and virtual reality (VR) display systems.

In stark contrast, perovskite emitters distinguish themselves with remarkably narrow FWHM values of approximately 20 nm, uniquely positioning them as the only viable class of materials capable of meeting the Rec. 2020 standard. Beyond their spectral precision, their superior optoelectronic properties and cost-effective synthesis routes underscore their potential to redefine luminance and energy efficiency benchmarks across emerging visual technologies. The perovskite family, already recognized for facile tunability, offers promising elasticities in emission wavelength and enhanced robustness when properly engineered, consolidating interest from both academic and industry stakeholders toward their widespread deployment.

Over the last decade, the research group under Professor Lee’s leadership has been at the vanguard of perovskite light-emitting diode (PeLED) innovation. Beginning with foundational patents secured in 2014, the team rapidly pushed external quantum efficiencies (EQE) of PeLEDs from a modest 0.1% to an impressive 8.53% within a year—an achievement that was highlighted in Science. This milestone established a foothold for perovskite emitters in the competitive landscape of light-emitting technologies. Subsequently, the group’s persistent refinement elevated EQEs beyond the 20% commercialization threshold, culminating in a near-theoretical-limit EQE of 28.9% coupled with operational lifetimes surpassing 30,000 hours as published in Nature in 2022. These strides not only advanced technical benchmarks but also addressed critical stability challenges that have historically hampered commercial viability.

Recognizing the importance of bridging laboratory success with market adoption, Professor Lee founded SN Display Co., Ltd., a technology enterprise actively showcasing perovskite-based display prototypes on prominent global platforms such as the Consumer Electronics Show (CES) and Mobile World Congress (MWC). The company’s breakthrough performance at CES 2026, where it captured the Innovation Award—a first for perovskite technology—validated the commercial and scientific relevance of their sophisticated emitter development. These demonstrations signal a tangible shift in industry perception, instilling confidence in perovskite materials as key enablers for next-generation ultra-high-definition display products.

Addressing the fundamental challenges of high-quality PeNC synthesis, this study refutes longstanding conventions that relied heavily on the ‘hot-injection’ method. Traditionally, this approach involves injecting precursors into hot solutions exceeding 150 °C, a practice fraught with safety concerns related to rapid temperature fluctuations and potential fire hazards. Additionally, the method necessitates complex facilities engineered to shield sensitive reactions from oxygen and moisture, further complicating scale-up efforts. Attempts at room temperature synthesis techniques like ‘ligand-assisted reprecipitation’ have been hindered by rapid precipitation, leading to inconsistent crystal size distributions and diminished productivity during mass production—obstacles that have hindered transition from the lab to commercial output.

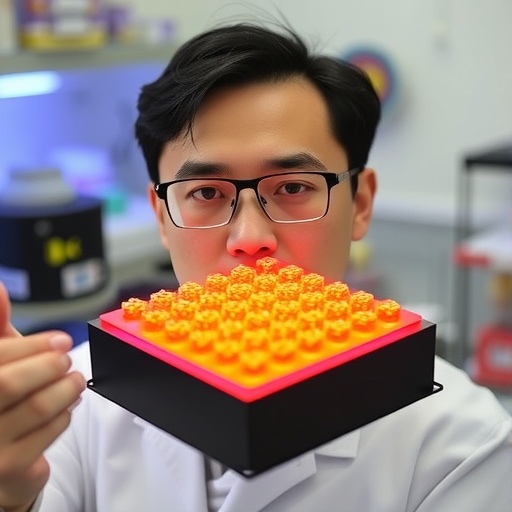

In a striking departure from these methods, Professor Lee’s team engineered a ‘cold-injection’ synthesis protocol, operating near 0 °C to mitigate thermal risks and simplify infrastructure needs. By dramatically lowering the reaction temperature, they circumvent inherent dangers of heat and minimize environmental sensitivity, thus streamlining the production pipeline. This lowered-temperature regime facilitates a novel ‘pseudo-emulsion’ reaction mechanism that effectively retards crystal nucleation and growth, curtailing defect formation and fostering the growth of highly crystalline, uniform nanocrystals. The pseudo-emulsion phase acts as an intermediary state that stabilizes precursor interactions, enabling precise control over particle morphology and purity at scales previously unattainable.

The implication of this cold-injection methodology extends remarkably into industrial scalability. Even when translated to large-volume reactors of 20 liters—a scale indicative of commercial readiness—the process yields PeNCs with near-unity PLQY (~100%), mirroring results typically confined to milliliter lab experiments. Crucially, PeLED devices fabricated using these bulk-produced nanocrystals have demonstrated world-leading efficiencies, achieving an EQE of 29.6%. Perhaps most compellingly, the research collaboration with SN Display has realized practical applications by creating color conversion films derived from these industrial-scale PeNCs, which have been successfully integrated into operational tablet displays, offering a vivid demonstration of their transformative potential in consumer electronics.

Professor Tae-Woo Lee expressed enthusiasm over the breakthrough, stating that the cold-injection method pioneers a path for mass manufacturing of perovskite nanocrystals without compromising on efficiency or consistency. He emphasized that this scalable and safe synthesis route could act as the linchpin to unprecedented commercialization opportunities for perovskite-based display technologies, propelling them toward mainstream adoption in markets demanding superior color fidelity and visual immersion.

This latest publication marks a continuation of Seoul National University’s prolific contributions to optoelectronic material science, being the third high-impact paper appearing in Nature and Science journals in 2026 alone. The sustained output reflects the team’s extraordinary commitment to advancing both the fundamental understanding and practical application of novel luminescent materials, solidifying their standing as global leaders in the convergence of nanomaterials and display engineering.

Support for this pioneering research was provided through several prestigious Korean governmental funding programs, including grants from the National Research Foundation of Korea (NRF) and various Technology Innovation Programs under the Ministries of Science, ICT, Trade, and Industry. This robust funding ecosystem underscores the strategic national importance of developing advanced display materials to bolster Korea’s leadership in the global electronics sector.

Seoul National University’s College of Engineering, renowned for cultivating technological pioneers, continues to nurture innovation through its comprehensive academic environment encompassing 12 departments and 323 distinguished full-time faculty members. Professor Lee’s laboratory exemplifies this ethos, blending cutting-edge materials research with entrepreneurial ventures that accelerate the transition from scientific discovery to impactful commercial success.

The convergence of recent achievements in high-efficiency PeLEDs, coupled with the scalable cold-injection synthesis process, signals a pivotal inflection point for perovskite emitters. These developments may soon translate into brighter, more vivid, and cost-effective displays within consumer electronics, AR/VR platforms, and beyond, fundamentally shaping the way visual content is experienced worldwide.

Subject of Research: Not applicable

Article Title: Cold-injection synthesis of highly emissive perovskite nanocrystals

News Publication Date: 18-Feb-2026

Web References: DOI: 10.1038/s41586-026-10117-2

Image Credits: © Seoul National University College of Engineering / Professor Tae-Woo Lee’s Lab

Keywords

Perovskite nanocrystals, cold-injection synthesis, photoluminescence quantum yield, next-generation displays, Rec. 2020 color standard, narrow emission width, PeLED efficiency, scalable nanocrystal production, pseudo-emulsion mechanism, industrial-scale synthesis, augmented reality displays, virtual reality displays