An oil-free super-lubricant created from potato proteins could pave the way for sustainable engineering and biomedical applications, thanks to research led by the University of Leeds.

An oil-free super-lubricant created from potato proteins could pave the way for sustainable engineering and biomedical applications, thanks to research led by the University of Leeds.

The team says the groundbreaking aqueous material can achieve super lubricity or near zero friction by mimicking actions found in biology, such as the synovial fluids which articulate cartilage in human joints.

Engineering an eco-friendly, efficient, and functional aqueous lubricant has eluded researchers until now. Many, if not most, aqueous lubricants use materials that are nearly exclusively derived from synthetic chemistry.

The interdisciplinary team which included researchers from the University of Leeds School of Food Science and Nutrition, the Weizmann Institute of Science in Israel, King’s College London and INRAE, France, used alternative proteins such as potato protein as eco-friendly building blocks which can be naturally sourced as a by-product and have a lower carbon footprint. The results of their research are published today in the journal Communications Materials.

Lead author Anwesha Sarkar who is a Professor of Colloids and Surfaces in Leeds’ School of Food Science and Nutrition, said: “This is a revolutionary material engineering paradigm for biomedical applications and is a key milestone towards achieving highly sustainable, plant-based aqueous lubricant materials.

“What we have done is create a self-assembly of plant protein-based protofilaments with biopolymeric hydrogels in a patchy architecture.

“Combining multiscale experimental measurements with molecular dynamics simulations, our unprecedented results reveal how a self-assembly can be fabricated using plant proteins to deliver super lubricity via hydration lubrication. “

First author Olivia Pabois, Postdoctoral Fellow in Leeds’ School of Food Science and Nutrition said: “What we have created could well be the next generation of engineered biomedical materials for uses such as artificial synovial fluid, tears, and saliva.

“It could also be used for low-calorie foods where you can achieve low fat items without compromising the fatty feel of higher fat content counterparts.”

The researchers used facilities at the Weizmann Institute of Science in Israel where they were given access to state-of-the-art techniques for measuring surface forces and where they were able to study the surface morphology and nanotribology of the lubricants.

Professor Jacob Klein added: “The publication of this exciting work is the culmination of contacts with Professor Sarkar which started in 2019 and is an excellent example of international collaboration where the overall achievement is significantly greater than the sum of its parts.”

Professor Chris Lorenz from King’s College London commented: “As part of this interdisciplinary team led by Professor Sarkar, we were able to combine our expertise in molecular dynamics simulations with the experimental expertise of the other groups to link the molecular scale details of this exciting plant protein-based lubricant to its amazing lubrication properties.

“As a result, by being able to quantify the interactions which govern the assembly of the plant proteins and the hydrogel, as well as the absorption of this lubricant onto surfaces, we open the doors to potentially unlocking the ability to rationally design self-assembled structures of natural materials that optimise their lubrication properties.”

Dr. Marco Ramaioli from INRAE France added: “I was very happy to contribute to this promising study that aligns perfectly to INRAE’s objectives of laying the basis for a sustainable bio-based economy, replacing fossil-fuel-based materials and energies with their biomass-based counterparts.”

Ends

Further information:

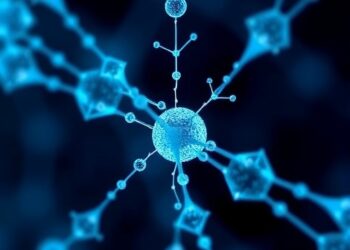

Caption: Schematic illustration of hydration lubrication. The green mesh represents the potato protein-based protofilaments (PoPF) partially coated by orange-coloured filaments connected to each other representing the xanthan-based hydrogels (XGH) where the naked part of PoPF (i.e., uncoated by XGH) interacts with the tribo-contact surfaces shown as grey-coloured ball and the rectangular slab. The hydration lubrication mechanism is shown schematically by the transparent water-like spheres attached to the XGH.

The DOI number is 10.1038/s43246-024-00590-5.

The research was funded by the European Research Council

For media enquiries, please contact Kersti Mitchell via k.mitchell@leeds.ac.uk

University of Leeds

The University of Leeds is one of the largest higher education institutions in the UK, with more than 40,000 students from more than 137 different countries. We are renowned globally for the quality of our teaching and research.

We are a values-driven university, and we harness our expertise in research and education to help shape a better future for humanity, working through collaboration to tackle inequalities, achieve societal impact and drive change.

The University is a member of the Russell Group of research-intensive universities, and is a major partner in the Alan Turing, Rosalind Franklin and Royce Institutes www.leeds.ac.uk

Follow University of Leeds or tag us in to coverage: Twitter | Facebook | LinkedIn | Instagram

Journal

Communications Materials

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Self-assembly of sustainable plant protein protofilaments into a hydrogel for ultralow friction across length scales

Article Publication Date

3-Sep-2024