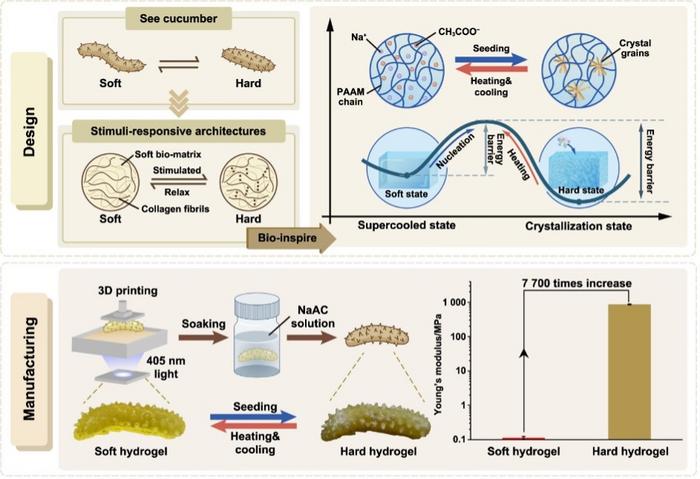

A groundbreaking advancement in hydrogel technology has emerged from the laboratories of Zhejiang University, where researchers have developed a novel 3D-printed hard/soft switchable hydrogel that defies conventional material limitations. This innovative hydrogel possesses the remarkable capability to reversibly transition its mechanical stiffness across an extraordinary range—shifting from the soft, flexible realm of kilopascals (kPa) to the rigid, industrial-grade stiffness of gigapascals (GPa). The underlying mechanism driving this dramatic transformation is the precise control of phase transitions within a supercooled hydrated salt solution infused in the hydrogel matrix, marking a significant breakthrough in the field of material science and 3D printing.

Traditionally, hydrogels have been prized for their softness, elasticity, and high water content, which enable their use in applications ranging from flexible electronics to biomedical devices. However, their inherent softness, typically characterized by an elastic modulus below 1 MPa, limits their utility in scenarios demanding higher mechanical robustness. Attempts to ameliorate this have predominantly focused on enhancing toughness rather than hardness, leaving a critical performance gap for hydrogels in demanding industrial roles. The innovation introduced by the Zhejiang University team addresses this gap through the strategic manipulation of the hydrogel’s solvent component—a supercooled hydrated salt solution capable of undergoing rapid, controlled crystallization.

The team’s approach centers on infusing a phase transition hydrated salt solution into a pre-printed hydrogel structure using advanced 3D photoprinting techniques. In its supercooled liquid state, the salt solution remains stable, rendering the hydrogel soft and pliable with mechanical properties akin to conventional hydrogels. This state is characterized by a disordered arrangement of solvent molecules within the polymer network. However, upon artificial seeding—triggering nucleation sites within the system—the supercooled solution rapidly crystallizes. This in-situ crystallization produces a dense network of rigid nanoscale crystals throughout the hydrogel, which significantly stiffen the material and elevate its Young’s modulus to an impressive 1.2 GPa—a figure that rivals hard plastics and surpasses the mechanical performance of all previously reported 3D-printed hydrogels.

Such a dramatic modulation of material properties presents exciting opportunities for hydrogel applications that were previously unattainable. For example, the researchers demonstrated a smart medical plaster bandage prototype utilizing this hard/soft switching capability. In its soft state, the bandage can conform intimately to the contours of a patient’s limb, promoting comfort and ease of application. Subsequently, within roughly ten minutes of induced crystallization, the bandage hardens to provide robust mechanical support and protection to the injured site. This dual-functionality not only exemplifies the hydrogel’s versatility but also opens new avenues in personalized medical devices and adaptive biomechanics.

Quantitatively, the hardened hydrogel achieves a Shore D hardness of 86.5, which is on par with commercial hard plastics used in industrial applications. Moreover, it exhibits a compressive strength of 81.7 MPa, signifying exceptional resistance to deformation under stress. These parameters corroborate the hydrogel’s suitability for roles demanding durability and load-bearing capacity, which are traditionally the domain of rigid synthetic materials. The toggling ability between such diverse mechanical states through non-invasive triggering places this hydrogel at the cutting edge of smart materials research.

Despite these promising enhancements in hardness and strength, the hydrogel’s toughness—its ability to absorb energy and resist crack propagation—remains suboptimal. The researchers acknowledge this limitation and are actively pursuing ongoing efforts to engineer the polymer networks and crystal morphologies within the composite material to improve its toughness while preserving its remarkable hardness and strength. Such advancements would further solidify this hydrogel as a paradigm-shifting material for extreme manufacturing environments.

The innovative exploitation of the solvent’s phase transition behavior rather than solely altering polymer chemistry exemplifies a paradigm shift in hydrogel design philosophy. Whereas previous modifications focused on cross-linking density and polymer architecture, this study highlights the pivotal role of solvent dynamics in determining hydrogel mechanical performance. By harnessing the metastable supercooled state and controlled crystallization kinetics, the team unlocks a previously underutilized design dimension, which could revolutionize future hydrogel-based materials.

This research heralds an exciting new horizon for multifunctional hydrogels capable of dynamically tuning their mechanical properties to meet diverse application demands. Potential fields poised to benefit include soft robotics, where adaptable stiffness is crucial; flexible electronics requiring robust yet compliant substrates; regenerative medicine involving tissue scaffolds that balance support with biocompatibility; and wearable devices necessitating conformable yet protective materials. The scalable 3D printing manufacturing approach further ensures that this breakthrough can be translated from laboratory innovation to industrial-scale production.

The work, published in the International Journal of Extreme Manufacturing, underscores the extraordinary potential anchored in material science advancements that meticulously integrate phase behavior and additive manufacturing. Such innovations pave the way for intelligent materials that eschew traditional trade-offs and realign functional capabilities across unprecedented mechanical ranges. By bridging softness and stiffness through reversible crystallization, the Zhejiang University team sets a new benchmark in hydrogel technology and smart material systems.

Looking ahead, the integration of tuning parameters such as crystal size distribution, salt solution concentration, and polymer network topology presents rich avenues for material optimization. Coupling these parameters with external stimuli control—including temperature modulation, localized seeding, or mechanical stress—could enhance the hydrogel’s responsiveness and tailorability for bespoke applications. The confluence of chemical engineering, physics, and additive manufacturing embodied in this research exemplifies the interdisciplinary nature propelling materials innovation.

In summary, the sea cucumber-inspired 3D-printed hard/soft switchable hydrogel ushers in a new class of adaptive materials that challenge the conventional boundaries of hydrogel utility. Exploiting reversible phase transitions within the infused supercooled hydrated salt solution enables controllable modulation of mechanical properties across three orders of magnitude. This discovery not only advances fundamental understanding of polymer-solvent interactions but also offers tangible solutions for the pressing need of mechanically robust yet flexible materials in advanced manufacturing disciplines. As research continues to enhance performance aspects such as toughness, the future promises transformative applications spanning medicine, robotics, electronics, and beyond.

Subject of Research: Hard/soft switchable hydrogels with tunable mechanical properties via phase transition hydrated salt solutions infused in 3D-printed polymer matrices.

Article Title: 3D printing of hard/soft switchable hydrogels

News Publication Date: 19-Mar-2025

Web References:

- International Journal of Extreme Manufacturing: https://iopscience.iop.org/journal/2631-7990

- DOI Link: http://dx.doi.org/10.1088/2631-7990/adbd97

Image Credits: By Guofeng Liu, Pengcheng Xia, Weicheng Kong, Tianhong Qiao, Yuan Sun, Wenjie Ren and Yong He

Keywords: Hydrogel, 3D printing, switchable hardness, supercooled hydrated salt solution, phase transition, crystallization, smart materials, Young’s modulus, additive manufacturing, medical bandage, soft robotics, material science