In a groundbreaking advancement poised to reshape pharmaceutical manufacturing, LyoWave Inc., a pioneering company emerging from Purdue University’s innovative research ecosystem, has secured a $304,436 Phase I Small Business Innovation Research (SBIR) grant from the National Science Foundation. This significant funding aims to propel forward LyoWave’s cutting-edge microwave heating technology designed to revolutionize the lyophilization—commonly known as freeze-drying—process for injectable medicines, vaccines, and diagnostic reagents. Freeze-drying, a critical technique for preserving perishable pharmaceutical products by removing moisture under low temperature and pressure, is notoriously time-consuming and costly. However, LyoWave’s novel approach harnesses high-frequency microwaves at radar and satellite communication bands that offer a quantum leap in efficiency and throughput.

LyoWave’s technology, developed under the guidance of Purdue’s esteemed researcher Alina Alexeenko, employs tunable microwave frequencies far beyond the conventional 2.45 gigahertz range typical of standard microwave sources. By leveraging higher frequencies, the microwaves penetrate frozen pharmaceutical materials more effectively and uniformly, accelerating the sublimation of ice and reducing drying times substantially. This technique sidesteps thermal gradients and hotspots that frequently plague traditional microwave drying methods, thereby ensuring product stability and uniformity in large-scale manufacturing contexts. The company’s approach not only shortens the overall freeze-drying cycle but also decreases energy consumption and operational costs, making lifesaving medicines more accessible and affordable.

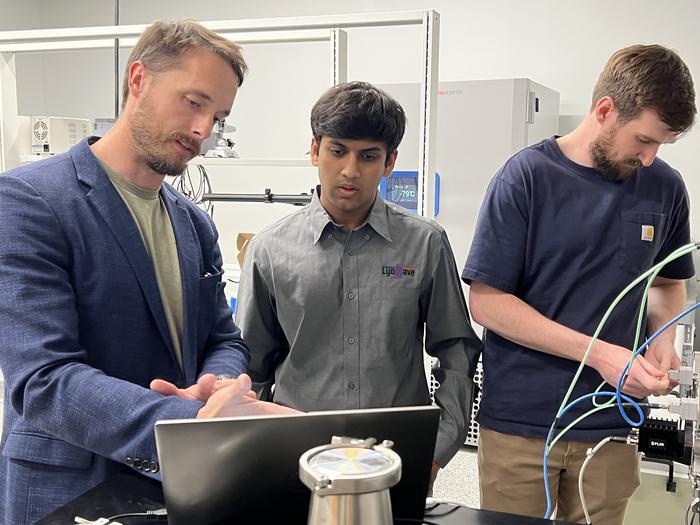

The recently funded SBIR project, titled “Scaling Up Tunable High-Frequency Microwave Heating for Pharmaceutical and Biologics Manufacturing,” intends to transition this laboratory-scale innovation into commercially viable, high-throughput manufacturing platforms. LyoWave is focusing on understanding the core scaling parameters necessary to maintain precision heating control at volume production levels—crucial for meeting stringent pharmaceutical quality standards. CEO Drew Strongrich, a 2021 PhD graduate from Purdue’s School of Aeronautics and Astronautics, emphasizes that the success of this technology could overhaul how injectable pharmaceuticals, vaccines, and biologics are produced, effectively increasing global medicine availability while reducing developmental bottlenecks.

Integral to LyoWave’s escalating growth is its licensing agreement through the Purdue Innovates Office of Technology Commercialization, which ensures that the underlying patented and patent-pending technologies reach markets beyond academia. The technological foundation was laid by Professor Alexeenko’s team in Aerospace and Aeronautics, where interdisciplinary expertise in fluid dynamics, classical mechanics, and microwave radiation converged to solve fundamental challenges in freeze-drying processes. By marrying aerospace sensor technology and microwave material processing, LyoWave exemplifies how cross-domain innovation can spawn novel industrial applications with high societal impact.

Lyophilization has traditionally faced limitations related to slow drying rates and non-uniform temperature distribution, especially in large batch manufacturing. Conventional heating via conduction or convection is insufficiently precise and often leads to degradation of sensitive biological molecules. LyoWave’s microwave heating method introduces volumetric energy deposition directly into the frozen matrix, substantially increasing drying velocity while preserving molecular integrity. This method enhances process throughput, enabling pharmaceutical companies to scale up production without compromising quality, a decisive factor amid escalating demand for vaccines and therapeutic biologics worldwide.

The synergy between LyoWave and Purdue University’s research infrastructure is further bolstered by collaborative industry partnerships, including a recent joint development agreement with Millrock Technology—a leader in state-of-the-art freeze-drying equipment. Combining Millrock’s expertise in biotechnology freeze dryers with LyoWave’s microwave innovations sets a new standard for freeze-drying capabilities ranging from benchtop prototypes to full-scale commercial operations. This collaboration reflects a strategic alignment designed to accelerate the commercialization timeline and integration of advanced microwave drying into existing pharmaceutical manufacturing chains.

Complementing the NSF’s SBIR support, LyoWave has also attracted $50,000 in matching grant funding from the Indiana Economic Development Corp.’s Applied Research Institute, highlighting regional commitment to high-impact industrial biotechnology startups. The company’s 2023 founding and subsequent seed investment from Handshake Ventures mark a swift trajectory from academic research to entrepreneurial enterprise. The confluence of university-backed intellectual property, robust financial backing, and industry partnerships positions LyoWave at the forefront of disruptive pharmaceutical manufacturing technologies.

From a technical perspective, the microwaves utilized by LyoWave operate at frequencies in tens of gigahertz, a spectral range traditionally reserved for radar and satellite communications. This shift in operational frequency enables rapid, highly tunable energy absorption profiles in frozen media. Unlike conventional microwave ovens or medical microwave therapies operating near 2.45 gigahertz, these high-frequency microwaves allow unprecedented control over penetration depth and heating uniformity. The tunability aspect gives manufacturers the flexibility to optimize energy deposition tailored to different formulations, vial sizes, and product geometries—an essential capability for scalable pharmaceutical applications.

Looking towards the future, successful scaling and commercialization of this technology could alleviate chronic supply chain constraints in critical vaccines and biologics. Faster, more efficient freeze-drying will not only reduce manufacturing turnaround times but also help stabilize fragile biomolecules that are central to next-generation therapeutics. As global health systems grapple with pandemic preparedness and expanding chronic disease treatment portfolios, innovations like LyoWave’s microwave freeze-drying could prove transformative in making advanced medicines more reliable and widely available.

Purdue Innovates’ Office of Technology Commercialization plays an indispensable role in shepherding LyoWave’s innovations through the often-complex path from lab discovery to market readiness. By managing intellectual property protection, licensing, and external partnerships, the office amplifies the economic and societal benefits of Purdue’s research endeavors. With more than 290 patents awarded in fiscal year 2024 alone, Purdue’s technology commercialization ecosystem stands as one of the nation’s most dynamic engines for translational research impacting diverse sectors, including pharmaceuticals, aerospace, and industrial engineering.

In sum, LyoWave’s microwave-enabled approach to pharmaceutical lyophilization exemplifies the power of interdisciplinary engineering and science to tackle persistent industrial challenges. By injecting breakthrough microwave technology into the freeze-drying process, the company not only advances manufacturing efficiency and product quality but also fosters a new paradigm in drug production that aligns with urgent public health needs. As funding and collaborations pave the way forward, this innovation heralds a future where lifesaving medicines can be produced faster, more uniformly, and more economically than ever before.

Subject of Research: Microwave-enhanced lyophilization technology for pharmaceutical and biologics manufacturing

Article Title: Revolutionizing Pharmaceutical Freeze-Drying: LyoWave’s High-Frequency Microwave Technology Accelerates Medicine Manufacturing

News Publication Date: Not explicitly provided

Web References:

– https://www.lyowave.com/

– https://purdueinnovates.org/otc/

– https://engineering.purdue.edu/AAE

– https://www.purdue.edu/newsroom/2024/Q2/lyowave-licenses-purdue-freeze-drying-innovations-enters-collaboration-with-millrock-technology/

– https://www.purdue.edu/newsroom/2023/Q3/purdues-microwave-technology-could-lead-to-more-stable-vaccine-supply-chain/

Image Credits: LyoWave photo/Alina Alexeenko

Keywords: Pharmaceuticals, Microwave radiation, Freeze-drying, Fluid dynamics, Materials science, Drug costs, Freezers, Physical sciences