In a groundbreaking achievement, a collaborative research team led by Professor Ma Yanwei from the Institute of Electrical Engineering of the Chinese Academy of Sciences has revolutionized the performance of iron-based superconducting wires. This remarkable advancement was made possible through an innovative strategy that employs asymmetric stress engineering to create high-density flux pinning centers, a method that significantly enhances the wires’ current-carrying capabilities. The findings of this transformative study have been published in the esteemed journal, Advanced Materials.

Superconductors are materials that exhibit zero electrical resistance and the expulsion of magnetic fields at very low temperatures. Iron-based superconductors, in particular, have garnered significant interest for their potential applications in high-field technologies such as particle accelerators, fusion energy devices, and advanced magnetic resonance imaging systems. While known for their impressive characteristics such as high critical fields and cost-effectiveness, these materials often suffer from brittle structures that pose challenges in achieving the necessary high density of flux pinning centers needed for robust current transport.

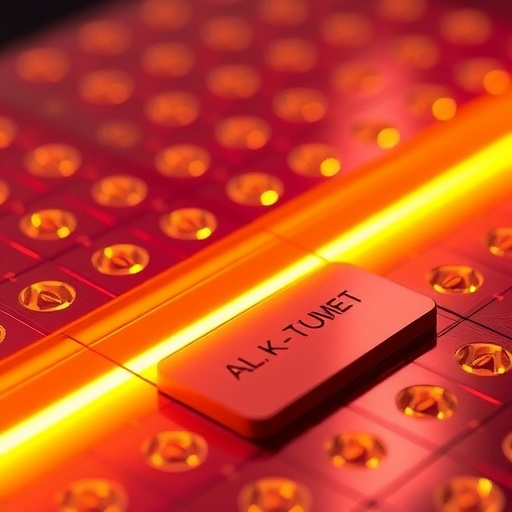

The research team’s novel approach involves the application of asymmetric stress fields to manipulate the microstructure of the superconducting wires. They successfully utilized scalable extrusion technology to exert precise control over hydrostatic pressure and shear stress. This manipulation led to localized lattice slip and twisting, resulting in a high density of dislocations. The process marks a significant departure from conventional methods, which have traditionally struggled to introduce such dense pinning centers within the brittle lattice structure of iron-based superconductors.

Furthermore, the researchers optimized these dislocations through a heat treatment process that formed ordered arrays, establishing an efficient network of flux pinning centers critical for improving current-carrying performance. The results of this meticulous engineering are nothing short of astonishing. The critical current density (Jc) of the newly engineered wires exhibited a marked increase, with Jc rising from 1.5×10⁵ A/cm² to an impressive 4.5×10⁵ A/cm² at a magnetic field of 10 tesla (T). In even more extreme conditions, at 30 T, the performance reached a remarkable 2.1×10⁵ A/cm², setting a new global record for iron-based superconducting wires and highlighting the potential of this innovative approach.

To achieve these remarkable injections of performance, the team faced the challenge of conducting tests in magnetic fields exceeding 30 T. This level of research was made possible by the state-of-the-art resources at the Steady High Magnetic Field Facility (CHMFL), a part of the Hefei Institutes of Physical Science. The facility’s water-cooled magnet, known as WM5, provided an essential experimental environment for validating the current-carrying capabilities of these wires under such extreme conditions, which Professor Ma emphasized as critical to ensuring the reliability and reproducibility of their breakthrough.

The implications of this research extend far beyond the realm of theoretical physics. It paves the way for a new and economically viable method for developing high-performance iron-based superconducting wires. The advancements could significantly accelerate the practical application of these materials in cutting-edge technologies that require strong magnetic fields, thereby positioning iron-based superconductors at the forefront of technological innovation and energy efficiency.

Moreover, the potential applications of these superconducting materials are vast. From enhancing medical imaging systems to revolutionizing energy storage solutions, the rise of highly efficient and reliable superconductors could result in substantial advancements in various fields of technology. The ability to efficiently transport electricity without resistance could also contribute to more sustainable energy systems and provide solutions to some of the pressing challenges faced by modern society.

As the research continues to unfold, further studies will delve into the scalability of these methods for mass production of high-performance superconducting materials. The collaboration among various institutions underlines the importance of interdisciplinary approaches in pushing the boundaries of contemporary scientific knowledge. This spirit of collaboration and innovation is essential as researchers aim to tackle the remaining challenges in the field of superconductivity.

In summary, the creation of high-density flux pinning centers through asymmetric stress engineering represents a significant leap forward in the field of superconductors. The capability to enhance the performance of iron-based superconducting wires opens new avenues for high-field applications, potentially transforming industries reliant on such technology. This work not only establishes a new benchmark for the performance of superconductors but also ignites keen interest in future explorations of the structural engineering of materials at the microscopic level.

With this latest advancement, the field of superconductivity stands on the brink of possible exponential growth, fueled by the innovative strategies employed by Professor Ma’s team and their commitment to enhancing the material properties essential for tomorrow’s technologies. As researchers across the globe take inspiration from these findings, the future of superconductivity promises to deliver astonishing discoveries that could shape the world as we know it.

Subject of Research: Engineering of Dense Dislocations in Iron-based Superconductors

Article Title: Asymmetric Stress Engineering of Dense Dislocations in Brittle Superconductors for Strong Vortex Pinning

News Publication Date: 22-Aug-2025

Web References: DOI link

References: Advanced Materials

Image Credits: JIANG Donghui

Keywords

Superconductivity, Iron-based superconductors, Flux pinning, Current density, Asymmetric stress engineering, Magnetic fields, Material engineering, High-performance wires, Energy efficiency, Advanced materials.