In a groundbreaking advancement within the field of chemical engineering and sensor technology, researchers A.K. Pathak and M. Kundu have unveiled a multifunctional soft sensor capable of significantly enhancing the monitoring and control of chemical reaction processes. This innovative development promises to revolutionize how chemical processes are monitored by utilizing impedimetric parameters, which are crucial for accurately assessing reaction dynamics.

The genesis of this research arose from the increasing complexity associated with chemical processes in a variety of industries, each requiring precise control and real-time monitoring to optimize efficiency and minimize waste. Traditional sensors have proven effective in many applications; however, they often lack the versatility and flexibility needed for modern chemical manufacturing environments. As a response to these challenges, Pathak and Kundu embarked on creating a novel sensor architecture that integrates multifunctional capabilities into a soft sensory platform.

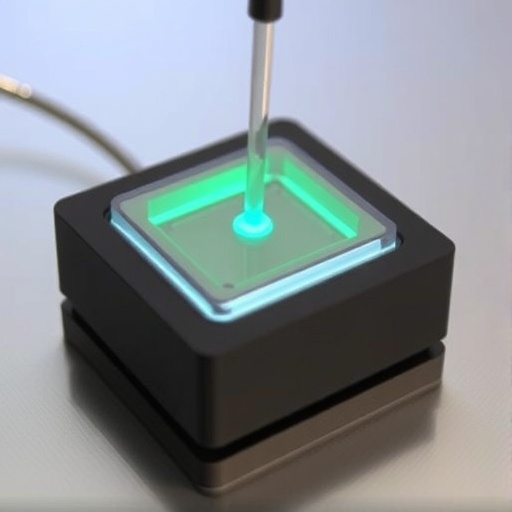

At the core of their innovation is the concept of impedimetric sensing, which involves measuring the impedance characteristics of a reaction medium. Impedance can provide insights into the conductivity of the medium, offering an indirect but informative view of the reaction conditions. This type of measurement is particularly advantageous as it can reveal chemical changes occurring in real time, allowing for timely interventions and adjustments, which is often key to achieving desired outcomes in reaction processes.

The newly designed soft sensor is not only sensitive to changes in the chemical environment but also exhibits remarkable flexibility. Unlike traditional rigid sensors, this soft version can comfortably conform to different shapes and surfaces, which is critical when monitoring reactions taking place in varied geometrical settings. This high degree of adaptability enhances its application across diverse chemical systems, potentially ranging from small-scale laboratories to large industrial plants.

Moreover, this multifunctional sensor is capable of simultaneous measurements of multiple impedimetric parameters. This is particularly beneficial because it enables comprehensive monitoring of a chemical reaction, as multiple factors such as temperature, concentration, and pressure can be tracked concurrently. The integration of these parameters into one sensor significantly reduces the need for multiple devices, resulting in less complexity, lower costs, and enhanced reliability.

In recent years, the role of artificial intelligence (AI) in enhancing sensor functionality has been increasingly recognized. The research team embraced this trend by incorporating AI algorithms within the sensor’s processing unit. By analyzing the data collected through the impedimetric measurements, these algorithms can predict the outcomes of the reaction and suggest modifications to optimize performance. This synergistic approach ensures that adjustments can be made proactively, aligning with the industry’s movement toward smart manufacturing techniques.

As the electronics industry continues to explore new materials for sensor fabrication, Pathak and Kundu’s choice of materials for creating the soft sensor is noteworthy. The sensor incorporates innovative polymer-based materials known for their electrical properties, which significantly enhance the sensitivity and range of the sensor. These materials not only support the functionality of the sensor but also ensure that it is lightweight and easy to deploy in various environments.

A major concern in chemical processing is the risk of hazardous conditions resulting from uncontrolled reactions. The development of this multifunction soft sensor addresses safety concerns head-on by providing critical data that can preemptively identify potential risks. By enabling operators to have detailed real-time insights into reaction conditions, the sensor aids in implementing necessary safeguards, thereby contributing to safer industrial practices.

Field tests conducted by the research team have demonstrated the efficacy of the multifunction soft sensor in practical applications. The tests illustrated its ability to detect subtle changes in impedance that correlate with reaction kinetics, highlighting the sensor’s potential in enhancing process control. As industries strive to meet heightened regulatory standards regarding safety and sustainability, the implementation of such advanced sensing technologies will be instrumental.

The overarching goal of this research is not only to innovate a new sensing technology but also to promote a paradigm shift in how chemical reactions are monitored and controlled. By leveraging state-of-the-art materials science and computational techniques, Pathak and Kundu aim to usher in a new era of intelligent chemical production. This vision aligns with global trends emphasizing automation and data-driven decision-making processes in the manufacturing sector.

In light of these advancements, manufacturers in the chemical sector, as well as sectors closely related to chemicals such as pharmaceuticals and bioengineering, could find substantial value in adopting such soft sensor technology. As firms continue to optimize their operations amidst ever-tightening competition, embracing multifunctional devices that deliver rich data insights will likely be a key differentiator.

As the researchers prepare to publish their findings in the prestigious journal “Ionics,” the academic and industrial communities are keenly anticipating the reception of their work. The integration of such innovative technologies has the potential to trigger significant advancements in other fields as well, further proving the versatility and impact of impedimetric sensing across various domains.

With a commitment to continuing their research and development efforts, Pathak and Kundu are poised to make further contributions to the field in the future. Their work not only sets a precedent for new sensor technologies but also encourages a culture of innovation that pushes the boundaries of what is possible in chemical engineering. The excitement surrounding this multifunction soft sensor signifies a promising step towards the next level of process control and safety in chemical production.

This pioneering research is expected to attract interest from academic researchers, industrial practitioners, and policy-makers keen to understand how these advancements can shape the future of chemical engineering and manufacturing. As industries worldwide look to enhance efficiency and sustainability in their processes, innovations such as the multifunction soft sensor become integral to achieving these goals.

In conclusion, as noted in their article published in “Ionics,” the development of this multifunction soft sensor using impedimetric parameters marks a significant milestone in the evolution of chemical reaction monitoring technology. The fusion of soft materials with advanced sensing techniques represents a bold new direction that could redefine standards in the industry. It encapsulates not just a technological advancement, but also a fundamental shift in how we think about chemical processing in the digital age.

Subject of Research: Development of a multifunction soft sensor for a chemical reaction process using impedimetric parameters.

Article Title: Development of a multifunction soft sensor for a chemical reaction process using impedimetric parameters.

Article References:

Pathak, A.K., Kundu, M. Development of a multifunction soft sensor for a chemical reaction process using impedimetric parameters.

Ionics (2025). https://doi.org/10.1007/s11581-025-06834-9

Image Credits: AI Generated

DOI:

Keywords: multifunction soft sensor, impedimetric parameters, chemical reaction processes, real-time monitoring, sensor technology, AI integration, materials science, process control.