In the rapidly evolving landscape of additive manufacturing, the quest for precision, scalability, and material versatility remains relentless. Among the forefront of this technological revolution is metal jetting, a process that is increasingly becoming pivotal in industries ranging from aerospace to biomedical devices. A recent breakthrough by researchers Sukhotskiy, Pascall, and Jeffries, outlined in their publication in npj Advanced Manufacturing, promises to revolutionize metal jetting by enabling multi-resolution droplet-on-demand printing through an innovative approach known as tailored pulsing. This advancement not only enhances print fidelity but also introduces unprecedented control over droplet size and deposition dynamics, potentially setting new standards in the manufacturing domain.

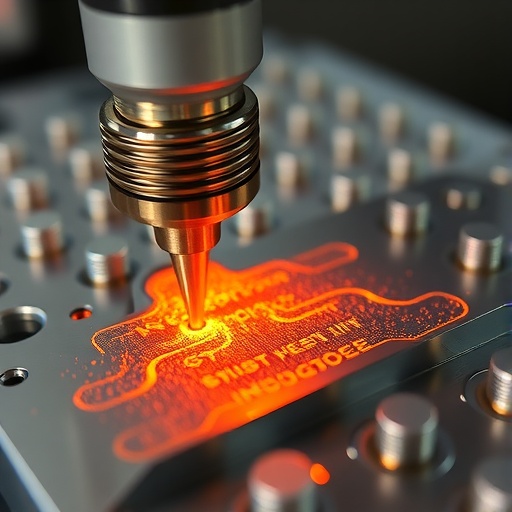

Metal jetting, fundamentally, involves the precise ejection of molten metal droplets from a printhead onto a substrate where they solidify to form complex three-dimensional structures. Traditional metal jetting techniques often grapple with limitations such as fixed droplet sizes and inconsistent layer resolutions, which constrain the ability to tailor parts for specific applications with varying scales of detail. The team’s approach circumvents these limitations by manipulating the temporal characteristics of the pulsing signal that actuates droplet ejection. Through this nuanced control, they have achieved a spectrum of droplet sizes within a single print job, facilitating a hybrid of macro and micro-features that amalgamate seamlessly in the final product.

Tailored pulsing, as the name suggests, involves customizing the waveform and frequency of the energy pulses supplied to the piezoelectric nozzles responsible for droplet formation. By adjusting parameters such as pulse width, amplitude, and delay intervals, the researchers can modulate the volume and velocity of individual droplets. This capability unlocks a multi-resolution paradigm where coarse structural components benefit from larger droplets, enhancing build speed and material deposition efficiency, while fine features are rendered with minuscule droplets to capture intricate geometries and surface textures with high fidelity. The underlying physics governing droplet formation here intertwines fluid dynamics, thermal gradients, and the rheology of molten metals, requiring a sophisticated interplay of simulation and experimental validation.

The implications of this technique transcend mere dimensional adjustments. Multi-resolution metal jetting opens avenues for functionally graded materials where variations in resolution correlate with localized changes in mechanical or thermal properties. By dynamically tuning droplet sizes and their placement, it becomes feasible to engineer gradients in porosity, microstructure, and alloy composition within a single printed object. This localized control paves the way for parts that are lightweight yet robust, heat-tolerant yet thermally insulative — properties that are invaluable in sectors such as aerospace propulsion and biomedical implant manufacturing.

Experimentally, the authors demonstrate the efficacy of tailored pulsing using a state-of-the-art metal jetting apparatus equipped with high-frequency piezoelectric actuators. Through high-speed imaging and droplet tracking techniques, they validate the formation of droplets ranging in diameter from tens to hundreds of micrometers. Their optimized pulse sequences exhibit stable droplet trajectories and depositions, minimizing satellite droplets and splatter, which often plague metal jetting processes and degrade print quality. The researchers further correlate their observations with computational fluid dynamics models that reveal the transient fluid flow within the nozzle channel during pulsing. This synergy of modeling and experimentation underpins the robustness of their multi-resolution droplet-on-demand system.

Beyond the basic science, this advancement has far-reaching practical ramifications. Manufacturers no longer need to compromise between print speed and resolution; instead, they can strategically deploy droplet sizes to expedite the fabrication of bulk regions while reserving fine-scale deposition for critical areas. This flexibility drastically reduces production times and costs without sacrificing part performance or surface finish. Moreover, the dynamic pulsing capability promises enhanced adaptability across a variety of metal alloys, including those with diverse melting points and viscosities, thus broadening the scope of feasible manufacturing materials.

The control over droplet ejection also offers notable improvements in process repeatability and reliability. In traditional metal jetting, maintaining consistent droplet formation requires meticulous calibration of fixed parameters. However, the tailored pulsing approach endows operators with a real-time tuning knob, adaptable to variables such as printhead wear or environmental fluctuations. This real-time adjustability could be leveraged in closed-loop control systems incorporating feedback from high-speed sensors and machine learning algorithms, further enhancing print quality and minimizing defects.

At a fundamental level, this research sheds light on the complex interrelation between actuation signals and molten metal dynamics. The team’s insights into droplet pinch-off mechanisms, ligament formation, and satellite droplet suppression contribute valuable knowledge to the physics of jetting. These findings can inform future nozzle designs optimized for multi-resolution printing, potentially leading to printheads with variable aperture geometries or advanced materials capable of withstanding the harsh thermal and mechanical cycling intrinsic to metal jetting.

This pioneering methodology also intersects with the ongoing trends in digital manufacturing towards mass customization. With multi-resolution control, manufacturers can produce bespoke components tailored to specific mechanical and aesthetic requirements without the prohibitive cost and lead-time of traditional tooling. For instance, aerospace components may integrate smoothly transitioning surface textures for aerodynamic efficiency alongside reinforced structural cores — all achieved within a single print run.

Importantly, the environmental and sustainability contexts of manufacturing stand to benefit from this innovation. By optimizing droplet placement and size, material wastage is significantly curtailed, aligning with circular economy principles. Enhanced control over microstructures translates to parts with longer lifespans and improved recyclability, thus reducing the ecological footprint of manufacturing operations.

Looking ahead, the potential integration of tailored pulsing with hybrid additive-subtractive manufacturing platforms could amplify part complexity and precision beyond current constraints. Coupled with in situ monitoring technologies and augmented reality interfaces for operator oversight, the multi-resolution droplet-on-demand metal jetting ecosystem envisioned by Sukhotskiy and colleagues heralds a paradigm shift in how metal components are conceived, designed, and fabricated.

Overall, this research represents a critical step towards the ultimate goal of fully digital, flexible, and intelligent manufacturing systems, capable of fabricating metal parts with unmatched complexity, speed, and performance. It encapsulates the innovative spirit driving the next generation of additive manufacturing, where physics-informed process control and advanced materials science converge to unlock new frontiers.

Sukhotskiy, Pascall, and Jeffries have provided not only a technical blueprint but also a visionary framework for realizing multi-resolution metal jetting. Their work beckons further exploration into tailoring jetting dynamics, optimizing waveform algorithms, and expanding material compatibility. As industries increasingly embrace bespoke manufacturing, the tailored pulsing methodology may well become a cornerstone technology defining the future of metal additive manufacturing.

Subject of Research: Multi-resolution droplet-on-demand metal jetting enabled by tailored pulsing techniques.

Article Title: Enabling multi-resolution droplet-on-demand metal jetting through tailored pulsing.

Article References:

Sukhotskiy, V., Pascall, A.J. & Jeffries, J.R. Enabling multi-resolution droplet-on-demand metal jetting through tailored pulsing. npj Adv. Manuf. 2, 19 (2025). https://doi.org/10.1038/s44334-025-00029-w

Image Credits: AI Generated