When Lasers Learn: Machine Learning Revolutionizes Metal Additive Manufacturing and Welding

Laser-based metal processing stands as one of the most versatile and transformative technologies in modern industry. From precision welding to additive manufacturing, lasers enable the fabrication of intricate components with remarkable speed and accuracy. Industries ranging from automotive and aerospace to medical technology increasingly depend on laser techniques to meet demands for customized, high-performance parts. Despite these advantages, laser metal processing remains exceptionally complex—and sensitive to the smallest fluctuations in materials and operational parameters. Even minor variations can introduce defects, jeopardizing product quality and increasing costs.

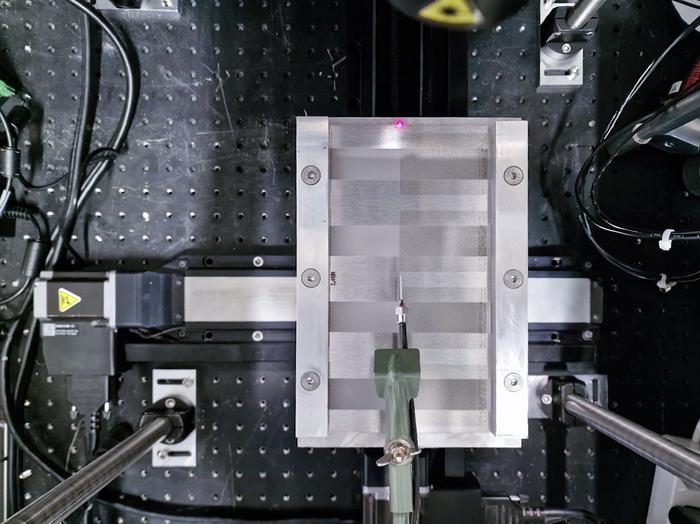

Recent breakthroughs at Empa, the Swiss Federal Laboratories for Materials Science and Technology, are set to change this landscape profoundly. A research team led by Elia Iseli in the Advanced Materials Processing laboratory has harnessed machine learning to develop new methodologies that vastly improve laser-based manufacturing processes. Two principal projects, helmed by researchers Giulio Masinelli and Chang Rajani, demonstrate how artificial intelligence can both reduce experimental overhead and enable real-time process optimization, heralding a new era of autonomous laser fabrication.

A key focal point concerns additive manufacturing of metals using laser powder bed fusion (PBF)—a method where a laser selectively melts layers of metal powder to build parts layer-by-layer. PBF offers a unique ability to realize geometries unattainable by traditional means. However, the process hinges delicately on balancing two fundamental laser-material interaction modes: conduction mode, where metal is melted gradually, and keyhole mode, which involves localized vaporization creating a deeper melt pool. Selecting operating parameters that tread this boundary correctly is vital. Conduction mode yields finer detail and is suited for thin components, while keyhole mode accelerates processing but risks defects if not precisely controlled.

The challenge lies in the fact that optimal settings vary widely—not only between different metals but between individual powder batches of the same material. This variability forces manufacturers to conduct extensive trial runs, adjusting laser power, scan speed, and other parameters through painstaking experimentation. As Masinelli points out, such a trial-and-error approach demands significant material, expert oversight, and time—barriers that often discourage smaller companies from adopting PBF technologies.

Addressing these hurdles, the Empa team utilized data from the optical sensors already embedded in modern laser machines. They trained a machine learning algorithm to interpret sensor readings and identify the current melting mode in real time. This system autonomously recommends parameter adjustments for subsequent trials, dramatically reducing the necessary number of experiments by roughly two-thirds. Crucially, this efficiency gain does not compromise the final component’s quality, democratizing access to PBF by reducing reliance on specialist knowledge and costly pre-production testing.

Yet the scope of their innovation extends beyond initial setup. Recognizing the unpredictability inherent during actual welding runs—such as surface defects causing erratic laser interactions—Rajani and Masinelli pushed the envelope further. They developed a closed-loop control mechanism that continuously monitors the welding process and dynamically adjusts laser parameters on the fly. Achieving such real-time responsiveness is a formidable challenge; the system must analyze sensor data and execute corrections within milliseconds to prevent defect formation.

To meet these demanding requirements, the team leveraged field-programmable gate arrays (FPGAs), specialized integrated circuits known for their predictable timing and parallel processing capabilities. Unlike conventional computers, FPGAs guarantee precise execution times for control commands, enabling ultra-fast feedback loops essential to adaptive laser welding. Meanwhile, the FPGA operates in tandem with a traditional PC, which processes data in the background and retrains the machine learning model. Successful algorithm upgrades developed on the PC can then be deployed directly to the FPGA, continuously enhancing its "intelligence" during production.

This synergistic hardware-software integration exemplifies a significant leap towards autonomous manufacturing systems. By fusing machine learning with embedded real-time control, the Empa researchers demonstrate a pathway toward laser welding processes that self-correct and optimize without human intervention. Such capabilities promise to elevate industrial throughput, reduce scrap rates, and foster the creation of complex metallic components with unprecedented consistency.

The implications of these advancements are vast. As industries push for lighter, stronger, and more customized metal parts, the ability to tune and control laser processes rapidly and precisely will be a critical competitive differentiator. Moreover, making these technologies accessible to non-experts could accelerate adoption across small and medium enterprises, broadening innovation beyond specialized laboratories.

Empa’s ongoing work includes continuing refinement of their algorithms and expanding their applicability to a broader range of metals and fabrication contexts. Collaborations with industry partners aim to integrate these intelligent controls directly into commercial laser machines, embedding autonomy into the firmware itself. This integration would transform access to sophisticated laser manufacturing, shifting the paradigm from manual parameter tuning to a largely self-governing process.

As the field of laser processing converges with artificial intelligence, the potential to push the boundaries of precision and efficiency appears limitless. The Empa team’s pioneering contributions illuminate a future where machines not only perform complex fabrication tasks but also learn and adapt in real time, ushering in a new generation of smart manufacturing technologies. This fusion of laser physics, sensor technology, and machine learning may well redefine what is possible in metal additive manufacturing and welding—and revolutionize industrial production on a global scale.

Subject of Research: Not applicable

Article Title: Autonomous exploration of the PBF-LB parameter space: An uncertainty-driven algorithm for automated processing map generation

News Publication Date: 5-Mar-2025

Image Credits: Empa