In the relentless quest to enhance additive manufacturing processes, a recent breakthrough study conducted by Bettencourt and Kouraytem sheds illuminating light on the fusion of two industrially pivotal alloys—SS316L and IN625. This research, published in npj Advanced Manufacturing, embarks on an in-depth comparative tensile analysis of bonding these metals using two cutting-edge techniques: laser powder bed fusion (LPBF) and directed energy deposition (DED). The findings hold formidable implications for industries reliant on high-performance metal components, from aerospace to energy sectors, where material integrity and mechanical robustness are paramount.

Additive manufacturing (AM) continues to revolutionize production methodologies by enabling complex geometries, reduced waste, and customizable properties. However, the fusion of dissimilar metals remains a challenging frontier due to disparities in thermal expansion coefficients, melting points, and microstructural behaviors. SS316L, a versatile austenitic stainless steel renowned for corrosion resistance, pairs with IN625, a nickel-based superalloy celebrated for high-temperature strength and creep resistance. Marrying these materials through AM demands meticulous control and understanding of process parameters to forge a strong, defect-free interface.

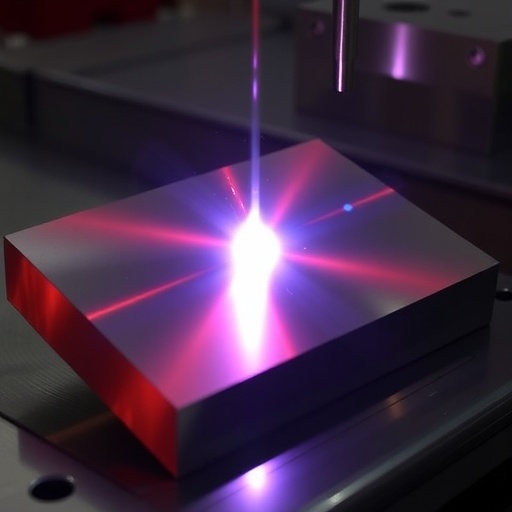

The study pivots on two prominent AM technologies. Laser powder bed fusion (LPBF) operates by selectively melting powder layers with a high-energy laser beam, achieving fine resolution and microstructural control. Conversely, directed energy deposition (DED) involves feeding metallic powder or wire directly into a molten pool created by a focused energy source, allowing for higher deposition rates and potential repair applications. Both methods offer distinct advantages and complexities when applied to multi-material fabrication.

Central to the research was the creation of a tensile testing matrix designed to probe the mechanical integrity of the SS316L-IN625 bond. This entailed fabricating samples via LPBF and DED, followed by rigorous mechanical testing to assess tensile strength, elongation, and fracture behavior. The investigation utilized advanced microscopy techniques to characterize the microstructural evolution within the bonded interface, aiming to correlate material properties with processing conditions.

The LPBF-fabricated samples exhibited a relatively homogeneous microstructure within each alloy region but demonstrated distinct transition zones at the interface, characterized by intermetallic compound formation and elemental diffusion gradients. These features critically influenced the tensile properties, with the interface region defining the failure modes in mechanical testing. Notably, LPBF samples displayed superior ultimate tensile strength compared to those produced by DED, attributed to finer microstructural features resulting from rapid solidification rates inherent to the technique.

Conversely, the DED samples manifested coarser microstructures and more pronounced elemental mixing at the interface, leading to different mechanical responses. While tensile strength was marginally lower, DED samples showed increased ductility, suggesting trade-offs between strength and toughness influenced by thermal histories and heating/cooling cycles experienced during deposition. The capability of DED to deposit larger volumes faster presents advantages despite these mechanical nuances.

Microscopic examinations illuminated the presence of certain brittle intermetallic phases within the interface, notably in DED specimens, which acted as stress concentrators under tensile loads. Managing these phases through process parameter optimization emerged as a critical challenge to prevent premature failure. The formation of such intermetallics, typically caused by elemental reactions between nickel and iron constituents, underscores the delicate balance required in multi-material additive manufacturing.

Another fascinating aspect highlighted by the research was the residual stress profile induced by both techniques. LPBF’s rapid solidification produced high tensile residual stresses necessitating post-processing heat treatments to alleviate potential cracking and distortion. In contrast, DED’s slower cooling rates generated relatively lower residual stresses but increased the risk of microstructural coarsening, impacting overall performance. Understanding and controlling these residual stress fields are vital for ensuring component reliability in service conditions.

The research also ventured into the parameter space governing laser power, scan speed, and powder feed rates, demonstrating that subtle adjustments can significantly influence the morphology and mechanical behavior of the bonded zone. For instance, higher laser power favored deeper melting and better intermixing but risked excessive dilution and undesirable phase formation, while lower settings preserved distinct interfaces but limited metallurgical bonding.

Implications for industry are profound. The ability to effectively bond SS316L and IN625 using LPBF or DED unlocks new design possibilities where components can leverage the corrosion resistance of stainless steel alongside the high-temperature performance of nickel superalloys. This fusion could enable parts that operate reliably in harsh environments, such as turbine blades with integrated cooling passages or chemical reactors exposed to aggressive media.

Moreover, the comparative insights empower manufacturers to select appropriate AM techniques based on specific component requirements. LPBF may suit applications demanding superior strength and fine detail, while DED could be favored for larger parts or repair tasks where build volume and deposition rate take precedence. Tailoring process parameters informed by nuanced understanding from such studies accelerates the maturation of multi-material additive manufacturing.

Looking ahead, the study advocates for expanded investigations encompassing fatigue testing, corrosion resistance evaluations, and real-world operational simulations to fully establish performance benchmarks. Integrating computational modeling with experimental data could further demystify microstructural evolution and predict failure mechanisms, paving the way for intelligent process designs.

The researchers underscore the importance of interdisciplinary collaboration, marrying materials science, mechanical engineering, and advanced manufacturing to surmount the intricate challenges inherent in bonding dissimilar metals. As AM technologies continue to evolve with enhanced precision and control, this foundational work charts a clear path toward harnessing the full potential of multi-material fabrication.

In summation, Bettencourt and Kouraytem’s comparative tensile analysis provides a compelling narrative on the capabilities and limits of LPBF and DED for joining SS316L and IN625. Their careful characterization of microstructures, mechanical properties, and process sensitivities delivers critical knowledge that will inform the next generation of high-performance, functionally graded components. This research epitomizes the transformative promise of additive manufacturing in material innovation and application diversification.

Through meticulous experimental work and insightful interpretation, the study not only advances scientific understanding but also inspires practical adoption of advanced AM techniques. The delicate marriage of stainless steel and nickel superalloy via targeted energy inputs exemplifies how additive manufacturing can transcend traditional fabrication boundaries, birthing novel engineering solutions imperative for future industrial demands.

Such advancements resonate beyond mere scientific curiosity, encapsulating the very essence of innovation where control over matter at micro and macro scales breeds components optimized for safety, longevity, and efficiency. As industries embrace these technologies, the fusion of dissimilar alloys through LPBF and DED is poised to redefine manufacturing landscapes with unprecedented design freedom and material performance.

Ultimately, this exploration underlines that the synergy between materials and additive manufacturing processes can unlock extraordinary engineering feats. Bettencourt and Kouraytem’s work stands as a testament to how rigorous research enables the transition from experimental novelty to industrial mainstay, heralding a new era in advanced manufacturing.

Subject of Research:

Bonding dissimilar metal alloys SS316L (austenitic stainless steel) and IN625 (nickel-based superalloy) through additive manufacturing techniques focusing on mechanical tensile properties.

Article Title:

Bonding SS316L and IN625 through laser powder bed fusion and directed energy deposition: a comparative tensile analysis.

Article References:

Bettencourt, C.J., Kouraytem, N. Bonding SS316L and IN625 through laser powder bed fusion and directed energy deposition: a comparative tensile analysis.

npj Adv. Manuf. 2, 30 (2025). https://doi.org/10.1038/s44334-025-00044-x

Image Credits:

AI Generated