Advancements in high-temperature gas-cooled reactors (HTGRs) are revolutionizing the future of nuclear energy systems. These reactors are increasingly recognized for their robust safety features and high thermal efficiency, enabling them to achieve temperatures essential for various industrial applications. Notably, thermal-hydraulic analysis plays a critical role in both the design and safety evaluation of these reactors, as it provides a means to understand the complex interactions between heat transfer and fluid flow within the reactor core.

However, traditional thermal-hydraulic analysis methods struggle to meet the need for accuracy and efficiency, primarily due to their reliance on two-dimensional models and outdated numerical algorithms. This limitation often hampers the ability of researchers to perform detailed three-dimensional (3D) analyses that are crucial for modern reactor designs. To address this growing challenge, a pioneering team led by Professors Lei Shi and Ding She has developed a groundbreaking computational software tool known as DAYU3D.

DAYU3D is designed specifically for three-dimensional thermal-hydraulic design and accident analysis within the context of HTGRs. By allowing researchers to conduct comprehensive 3D simulations, this code significantly enhances the analytical capabilities for thermal and nuclear engineering. With features that support 3D neutron kinetics simulations and the continuous modeling of control rod movements, DAYU3D stands as a modern solution to the limitations faced by conventional thermal-hydraulic codes.

The research initiative surrounding DAYU3D not only prioritizes precision but also embraces advanced technology. The software incorporates sophisticated radiation heat transfer calculations that are essential for understanding the energy exchange processes within the reactor. It also employs multi-scale and multi-batch modeling, which extends its applicability across a broad spectrum of temperature and pressure conditions that an HTGR might encounter during operation.

A key achievement of the development team is the optimization of DAYU3D’s numerical algorithms, which are integral to its enhanced performance. Through meticulous research into flow dynamics and heat transfer characteristics specific to HTGRs, the team devised an efficient flow-field solving method that vastly reduces the computational burden associated with traditional codes. With an innovative approach to global multi-batch fuel temperature calculations, DAYU3D boasts a remarkable reduction in computation time exceeding 60%. This efficiency gain is especially beneficial for engineering design iterations and large-scale analyses, making DAYU3D a resourceful tool in contemporary thermal-hydraulic studies.

The validation and testing of DAYU3D further underscored its reliability as a cutting-edge analytical tool. Over 100 test cases demonstrated the software’s ability to produce results with minimal deviances from reference solutions and experimental data. This not only reflects the code’s accuracy but also provides an invaluable asset for engineers and scientists engaged in developing and assessing HTGR designs.

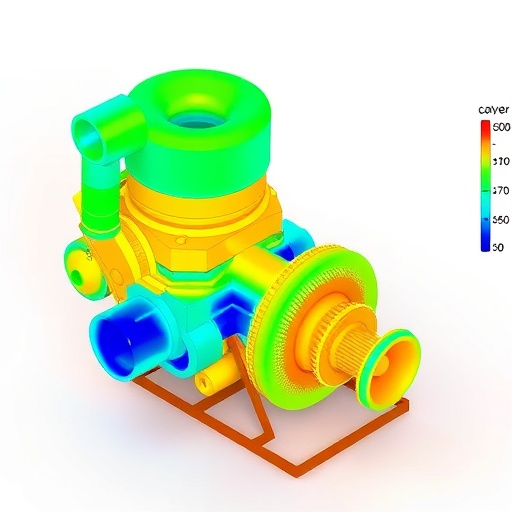

Perhaps one of the most exciting aspects of DAYU3D is its potential for visualizing 3D temperature distribution patterns within the reactor. By utilizing the software for simulations under both steady-state and accident scenarios, the research team mapped temperature profiles of the pebble-bed core and reactor pressure vessel. These findings offer critical insights into temperature behavior during normal and extreme scenarios, providing a solid foundation for future design modifications and safety evaluations.

Professors Lei Shi and Ding She acknowledge the significance of teamwork in creating the DAYU3D code, where their combined expertise in HTGR thermal-hydraulic design culminated in a powerful new tool. Looking beyond the current capabilities of DAYU3D, the team has ambitious plans for further enhancements. They aim to implement fully coupled simulations that integrate neutronic, thermal-hydraulic, and chemical corrosion processes, thereby enriching the analytical framework for HTGRs.

The lively debate surrounding the future of nuclear energy and its safety implications has taken a pivotal turn with the introduction of DAYU3D in the field. As the world increasingly turns to sustainable energy solutions, this software symbolizes a leap toward more efficient and safer nuclear reactor designs. Both research and industry communities are poised to benefit from such advanced capabilities, which could potentially attract a new generation of interest in nuclear energy.

In summary, the DAYU3D code represents a significant advancement in the thermal-hydraulic analysis landscape for high-temperature gas-cooled reactors. By addressing the limitations of traditional methodologies and providing an innovative 3D simulation environment, this tool is not just enhancing our understanding of HTGRs but is also contributing to a safer and more efficient future for nuclear energy systems.

The implications of the DAYU3D software extend far beyond academic circles. As engineers and designers seek modern solutions to the challenges posed by nuclear energy production, the insights gained from this advanced code have the potential to influence regulatory frameworks, industry standards, and public perception of nuclear technologies. With each iteration of the software, the research team at its helm remains staunch in its commitment to pursuing innovations that resonate with contemporary energy aspirations.

The complete study, detailing the advancements and methodologies of DAYU3D, can be accessed through the provided DOI link, promising to be a resource for those seeking to understand the forefront of nuclear science and engineering.

Subject of Research: Computational simulation/modeling for high-temperature gas-cooled reactors

Article Title: DAYU3D: a modern code for HTGR thermal-hydraulic design and accident analysis

News Publication Date: 9-Feb-2026

Web References: http://dx.doi.org/10.1007/s41365-026-01889-3

References: Not applicable

Image Credits: Credit: Hao-Jie Zhang

Keywords

Nuclear engineering, High-temperature gas-cooled reactors, Thermal-hydraulic analysis, Nuclear safety, Computational fluid dynamics.