In the pursuit of addressing the escalating global water scarcity, breakthroughs in membrane technology for seawater desalination remain a critical focus. Traditional thin-film composite polyamide membranes have long been heralded as the gold standard for water purification—particularly for reverse osmosis applications. However, these widely used membranes are hampered by inherent limitations, most notably the persistent trade-off between water permeance and ion selectivity. Furthermore, they suffer from chemical degradation, particularly under chlorine exposure, and are prone to fouling and mineral scaling, which shorten operational lifespan and efficiency. A recent landmark study introduces a novel approach that promises to transcend these longstanding limitations through the molecular engineering of hierarchically structured polymer nanofilms with semi-interpenetrating polymer networks (semi-IPN).

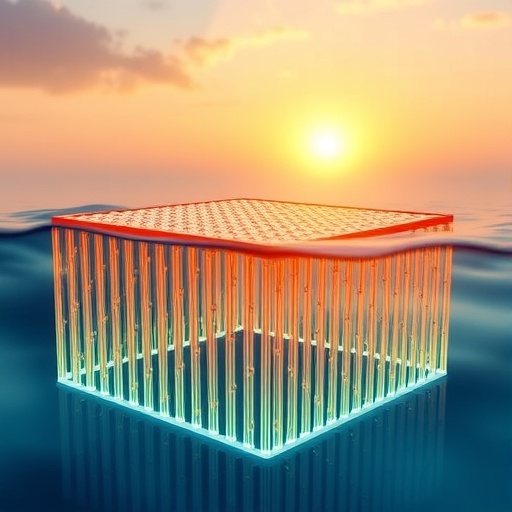

Published in Nature Water in 2026 by Chen et al., this study unveils a transformative strategy that combines polyamide with polyethylene glycol (PEG) networks to form semi-interpenetrating polymer nanofilms. Unlike conventional membranes formed only by interfacial polymerization of polyamide, these semi-IPNs include a PEG component intricately interlaced at the molecular level, creating a massively enhanced microstructure. This hierarchical assembly enables the formation of highly interconnected hydrated micropores on the subnanometer scale, creating finely tuned pathways for water molecules to permeate while rigorously excluding salt ions and other impurities.

The scientific ingenuity lies in harnessing macromolecule-regulated interfacial polymerization, a controlled synthesis approach that empowers precise manipulation of film architecture and pore dimensions. This advance makes it possible to fabricate membranes that span the spectrum from reverse osmosis-grade nanofiltration to ultrahigh selectivity membranes, adapting to diverse purification requirements. The PEG semi-IPN architecture not only improves water flux but crucially elevates ion permselectivity beyond the conventional trade-off boundary. This fundamental shift in membrane design challenges previously accepted limitations and sets a new benchmark for performance metrics.

In practical terms, the synergistic characteristics of polyamide and PEG within the semi-IPN facilitate a dramatic enhancement in water permeance without sacrificing rejection rates. This innovation means that membranes can achieve higher throughput and lower energetic costs for seawater desalination plants. Equally important, the presence of PEG networks imbues the membrane with exceptional resistance against chlorine degradation, a critical drawback in traditional membranes where chlorine, used as a disinfectant, rapidly deteriorates polymer structures. The semi-IPN design therefore extends membrane durability and chemical tolerance significantly.

Additionally, these newly engineered membranes demonstrate a remarkable robustness against biofouling—one of the most challenging operational threats to membrane longevity. The interconnected hydrated micropores formed by PEG create a hydration layer that discourages biological adhesion and proliferation of microbial communities. This anti-fouling property decreases maintenance demands and prolongs operational lifespan, making these membranes economically advantageous for large-scale desalination applications. The improved resistance to mineral scaling, achieved through the optimized pore structure and surface chemistry, further reinforces their performance reliability in harsh seawater environments.

Long-term operational stability is a pivotal criterion for seawater desalination membranes, and Chen and colleagues’ semi-IPN nanofilms deliver outstanding results under continuous, real-world conditions. Rigorous testing with simulated and actual seawater streams revealed that these membranes maintain superior flux and salt rejection capabilities over extended periods. This contrasts sharply with commercial polyamide membranes, which typically experience performance decay due to fouling and chemical attack. The longevity enhancement marks a crucial step toward sustainable, cost-effective desalination technologies that can meet growing freshwater demands globally.

From a materials science perspective, this work exemplifies the power of hierarchical polymer architecture in overcoming classical permeability-selectivity constraints. By integrating PEG molecular chains within the polyamide matrix, the researchers crafted a semi-IPN where PEG domains provide hydrophilicity and swelling, and polyamide domains offer mechanical strength and selectivity. The semi-IPN concept essentially decouples water transport from ion transport mechanisms, allowing independent tuning of each parameter for optimal desalination performance. This level of molecular precision in membrane engineering heralds a new era in membrane science.

Moreover, the fabrication process is readily scalable and compatible with existing membrane manufacturing infrastructure, addressing practical deployment concerns. The macromolecule-regulated interfacial polymerization can be implemented using commercially available monomers and PEG polymers, ensuring that translation from lab to market is feasible. By preserving the ultrathin film geometry characteristic of modern membranes while enhancing internal network complexity, the new membranes maintain high permeability while gaining robustness—a balance difficult to achieve with traditional membrane designs.

Environmentally, these high-performance membranes contribute to sustainable water resource management by lowering energy consumption during desalination due to higher permeance at lower pressure differentials. The anti-fouling and chlorine-resistant properties reduce the need for harsh chemical cleaning and membrane replacement, diminishing chemical waste and operational footprints. As climate change intensifies droughts and water shortages worldwide, such advances underscore the importance of material innovation in closing the gap between water demand and supply.

The research also opens intriguing avenues for customizable membrane development for specialized filtration needs beyond seawater desalination. By fine-tuning polymer network interpenetration and pore size distribution, membranes can be tailored for industrial wastewater treatment, brackish water filtration, or selective ion recovery from complex feed streams. The platform developed presents a robust foundation from which next-generation membrane technologies can evolve, combining multifunctionality with high durability.

Critically, this breakthrough addresses the key challenge that has stymied membrane scientists for decades: the simultaneous optimization of permeability and selectivity without degrading chemical and biofouling resistance. The semi-IPN polymer nanofilm represents a paradigm shift by demonstrating that hierarchical molecular design can effectively circumvent the trade-offs inherent in conventional polyamide membranes. Such advancements will accelerate the broader adoption of seawater desalination solutions that are economically viable, environmentally friendly, and technologically robust.

Future studies building on this work will likely focus on refining polymer chemistry and semi-IPN network topology to further enhance performance parameters and adapt membranes to emerging contaminants. Additionally, integrating these membranes into existing and next-generation desalination plants will provide crucial insights into scalability, lifecycle costing, and end-user impact. The interdisciplinary confluence of polymer science, chemical engineering, and environmental technology embodied here exemplifies the innovative spirit demanded by global water challenges.

In conclusion, the hierarchically semi-interpenetrating polymer nanofilms developed by Chen, Xu, Song, and collaborators offer a transformative leap forward in seawater desalination membrane technology. By seamlessly coupling polyamide’s selective properties with PEG’s hydrophilic semi-network, they have engineered membranes with unprecedented water permeance, chlorine resistance, and fouling mitigation. This innovation not only surpasses commercial membranes in performance but also heralds a sustainable and scalable platform to tackle the global water crisis. As the demand for freshwater intensifies, such breakthroughs illuminate the path toward clean, accessible water for all.

Subject of Research:

Development of hierarchically structured semi-interpenetrating polymer nanofilms for advanced seawater desalination membranes.

Article Title:

Hierarchically semi-interpenetrating polymer nanofilms for high-performance seawater desalination

Article References:

Chen, Y., Xu, J., Song, K. et al. Hierarchically semi-interpenetrating polymer nanofilms for high-performance seawater desalination. Nat Water (2026). https://doi.org/10.1038/s44221-025-00577-7

Image Credits:

AI Generated