A groundbreaking advancement in wearable health monitoring has emerged from a team of international researchers, heralding a new era where biosensors can stretch and flex seamlessly with the human body while continuously capturing a suite of physiological signals. By engineering a sophisticated hybrid microstructure (HMS) that unites wave-like flexibility with strategically positioned microcracks, this innovation addresses the perennial challenge of maintaining both mechanical durability and electrical stability in stretchable biosensors. This synergy allows devices not only to conform intimately to dynamic skin movements but also to deliver precise, reliable data streams from multiple biochemical and electrophysiological sources.

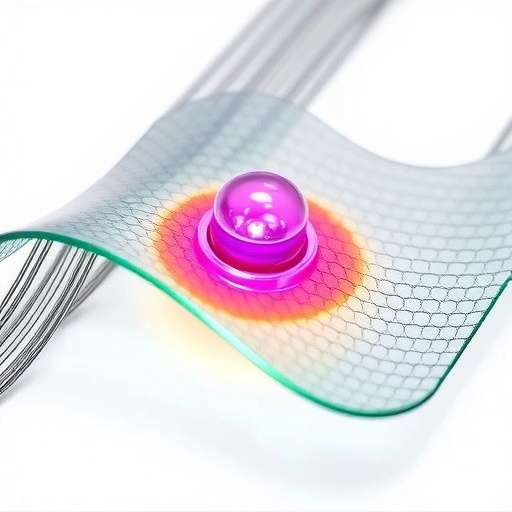

Traditional approaches to flexible electrodes have typically relied on wavy or serpentine designs to accommodate mechanical deformation. While these structures provide some degree of stretchability, they often suffer from stress concentration at the waves’ apexes, leading to accelerated mechanical fatigue and eventual failure during long-term use. Conversely, microcracked electrodes offer excellent stretchability by dispersing strain via crack propagation but risk intermittent conductivity loss due to microcrack growth. The HMS developed here cleverly integrates both principles, positioning microcracks at the peaks and troughs of the wavy gold electrodes deposited on flexible substrates. This hybridization results in efficient stress relaxation mechanisms, ensuring electrodes endure repeated large strains without compromising electrical performance.

The fabrication of these electrodes involves depositing gold on elastomeric substrates patterned into wavy geometries, followed by controlled induction of microcracks that run orthogonally to the wave direction. Finite element mechanical simulations reveal that this configuration dramatically reduces localized strain and stress, effectively redistributing mechanical loads. Remarkably, the electrodes maintain stable electrical conductivity even after 5000 cycles of stretching to 60% strain, a durability benchmark far surpassing previous flexible biosensors. This longevity is critical for real-world applications, where devices must reliably function amid the constant, complex mechanical stresses induced by bodily movements.

To transform these mechanically resilient electrodes into multifunctional biosensors, the researchers functionalized them with conductive polymers tailored for specific analyte detection. PEDOT:PSS coatings confer selective sensitivity to electrolyte ions such as calcium (Ca²⁺), sodium (Na⁺), and potassium (K⁺), which are vital indicators of hydration and metabolic status. Meanwhile, polyaniline (PANI)-based layers enable precise pH measurement, a parameter that reflects changes in sweat composition related to acid-base balance and physiological stress. These coatings preserve their sensing capabilities even under significant mechanical deformation, demonstrating exceptional electromechanical coupling within the HMS framework.

The entire sensor assembly is encapsulated in ultrathin films of Styrene-Ethylene-Butylene-Styrene (SEBS), which impart additional mechanical robustness and skin compatibility without sacrificing stretchability or breathability. The thin, soft encapsulation ensures conformal contact to the skin surface, minimizing motion artifacts that often plague wearable electronics. This design consideration is paramount for accurate, continuous biomarker monitoring during physical activities, including high-intensity exercise.

In human trials, a volunteer wore the integrated HMS biosensor during a sustained 20-minute running session. Throughout the exercise, the device accurately tracked transient fluctuations in sweat ion concentrations and muscle electromyography (EMG) signals in real time. The EMG data provide insights into muscle activation patterns and fatigue levels, complementing the biochemical markers drawn from sweat analysis. The sensor’s performance underscores its potential utility in sports science and rehabilitation, offering athletes and clinicians a powerful tool for monitoring physiological responses dynamically.

The combination of mechanical flexibility, chemical selectivity, and electrical reliability embodied in the HMS biosensors addresses longstanding barriers in wearable health technology. Prior devices often forced trade-offs between stretchability and multiplexed sensing, limiting their broader applicability. By contrast, this hybrid microstructure enables robust device operation under real-world, high-strain conditions while simultaneously capturing diverse biological signals on a single platform. This represents a pivotal step forward in the integration of multifunctional sensors for personalized health surveillance and management.

Professor Zhiyuan Liu, senior author of this study, emphasized the transformative potential of the HMS design, characterizing it as a “game-changer” that bridges a critical gap between mechanical adaptability and rich functional sensing. This innovation not only meets the rigorous demands of continuous, non-invasive monitoring but also expands the horizons of wearable technology applications. From tracking dehydration and electrolyte imbalances to detecting early muscular fatigue and potentially signaling disease onset, these sensors promise to empower proactive and data-driven healthcare.

Looking ahead, the research team aims to further refine this technology by enhancing breathability and scalability while integrating wireless communication modules for seamless connectivity. Such developments will facilitate the embedding of HMS biosensors into everyday garments or skin patches, promoting unobtrusive health monitoring in a variety of contexts—from athletic performance optimization to chronic disease management. The ability to concurrently monitor multiple physiological parameters in real time makes these biosensors ideally suited for the rapidly evolving landscape of digital health and personalized medicine.

The implications of this advancement extend well beyond consumer health, touching on broader societal challenges such as aging population management, remote patient monitoring, and occupational health surveillance. By enabling continuous, multimodal data acquisition without restricting user mobility, HMS biosensors could revolutionize how clinicians and individuals make informed decisions about wellness and intervention strategies. Such technologies could usher in a new paradigm where healthcare shifts from episodic assessments to continuous, anticipatory guidance.

In summary, the marriage of wave-like electrode structures with strategically engineered microcracks fosters a novel class of stretchable, multifunctional biosensors with unparalleled mechanical and sensing reliability. The integration of conductive polymer functionalization and thin-film encapsulation further enhances the device’s sensitivity and durability. As these versatile biosensors transition toward commercialization, they hold immense promise for revolutionizing personalized health monitoring, advancing scientific understanding of physiological processes, and ultimately improving quality of life across diverse populations.

Subject of Research: Advanced stretchable biosensors with hybrid microstructure electrodes for multimodal physiological monitoring

Article Title: Hybrid Microstructure Enables Highly Stretchable, Multifunctional Biosensors for Real-Time Sweat Ion, pH, and EMG Monitoring

News Publication Date: March 2025

Web References:

- https://www.sciencedirect.com/science/article/pii/S2667141724001265

- https://www.sciencedirect.com/journal/escience

References:

DOI: 10.1016/j.esci.2024.100327

Image Credits: Zhiyuan Liu, et al

Keywords: Microstructures, Stretchable biosensors, Hybrid microstructure, EMG sensing, Sweat ion monitoring, pH sensors, Conductive polymers, PEDOT:PSS, Polyaniline, Flexible electronics, Wearable health monitoring