In the rapidly evolving landscape of engineering and materials science, the quest to develop construction materials capable of withstanding extreme environments is gaining unprecedented momentum. Among the most challenging scenarios is the operation of infrastructure in low vacuum conditions, environments characterized by significantly reduced atmospheric pressure. These conditions are common in advanced aerospace applications, ultra-high-speed transportation systems, and frontier physics experiments, where traditional construction materials face profound durability challenges. Concrete, the cornerstone of modern construction due to its versatility and widespread availability, encounters unique mechanical and physicochemical stresses under low vacuum conditions, necessitating innovative approaches to enhance its performance and longevity.

Recent research conducted by Professor Long Guangcheng and his colleagues at Central South University’s Materials Research Institute is carving a new path in this domain. Their focus centers on augmenting concrete’s toughness and crack resistance through the introduction of polymer fiber reinforcements, an approach that capitalizes on the distinct advantages polymeric fibers offer. Polymers such as polyethylene and polypropylene, characterized by low density, high flexibility, corrosion resistance, and non-magnetic properties, present an ideal complement to the traditionally brittle nature of concrete when subjected to vacuum environments. The rigorous study conducted by this team bridges theoretical particle packing formulations with empirical mechanical testing to optimize concrete composites suited to these challenging operational milieus.

One of the pivotal challenges in low vacuum engineering environments is the accelerated dehydration of concrete matrices. Under reduced pressure, moisture content within concrete rapidly diminishes, initiating microstructural weakening and increased brittleness. This results in a pronounced susceptibility to critical phenomena such as drying shrinkage and crack propagation, which ultimately undermine structural integrity. Addressing these phenomena, the research integrates polymer fibers designed to absorb and redistribute stress concentrations, thereby mitigating crack initiation and growth. The team’s work harnesses particle dense packing theory, a mathematical framework optimizing aggregate and binder distributions to enhance compaction and minimize porosity, thereby refining the concrete’s microstructure in tandem with fiber reinforcement.

Empirical analysis involved subjecting polyethylene (PE) and polypropylene (PP) fiber reinforced concrete specimens to flexural loading under both atmospheric and simulated low vacuum conditions. This dual-environment testing strategy elucidated the differential mechanical responses elicited by pressure variations. The resulting load-deflection curves reveal that fiber reinforced composites exhibit enhanced toughness and post-cracking ductility compared to unreinforced concrete. Notably, PE fibers, endowed with superior tensile strength and elastic modulus, contributed more significantly to maintaining structural performance under vacuum conditions. This synergy between the mechanical properties of polymer fibers and the confining action exerted by coarse aggregates emerges as a foundational mechanism for sustaining concrete durability in challenging environments.

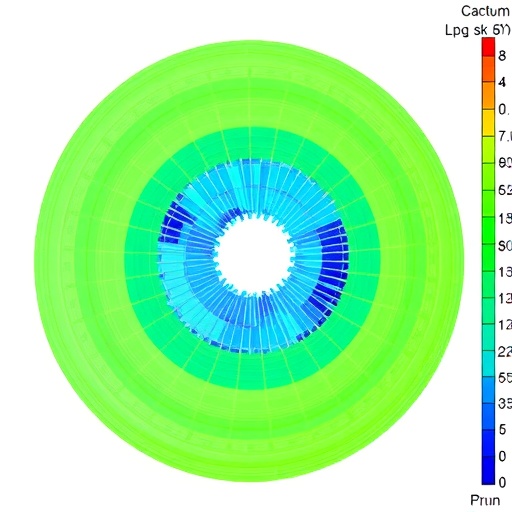

Complementing mechanical testing, the research incorporated advanced diagnostic techniques including acoustic emission (AE) monitoring and scanning electron microscopy (SEM) to interrogate the damage evolution and failure mechanisms at the microscale. Acoustic emission technology offers real-time insight into crack formation and propagation by detecting transient elastic waves generated by microfractures. The study found distinctive acoustic signatures correlating with vacuum-induced damage progression, allowing for a nuanced understanding of fiber-concrete interfacial behavior. SEM provided high-resolution imaging of fiber distribution, matrix porosity, and crack morphology, confirming the effectiveness of fiber-matrix bonding in restricting crack widths and impeding crack coalescence, factors crucial for long-term durability.

The interplay between fiber reinforcement and vacuum-induced mechanical stress is further complicated by the unique environmental interactions affecting polymer stability and adhesion properties. Polymer fibers must retain their mechanical efficacy while resisting degradation from environmental factors inherent to vacuum conditions, such as ultraviolet radiation and thermal cycling. The researchers’ choice of polyethylene and polypropylene fibers is strategic, as these polymers demonstrate resilience against these factors, ensuring that their reinforcing functions are sustained throughout the lifecycle of infrastructure components. This durability is critical for applications such as space habitats and low pressure pipelines where maintenance is impractical or economically prohibitive.

Professor Long’s team emphasizes that the optimization of the concrete matrix, fibers, and aggregate network constitutes a promising frontier for future research. Refinement of the particle size distribution and orientation of fibers can potentiate a structural composite that balances enhanced performance with economic viability. Contemporary computational modeling tools, including discrete element methods and finite element analysis, can be employed to simulate various matrix-fiber-aggregate configurations prior to physical prototyping, expediting the development cycle. Such advances would enable tailored designs for specific applications, adapting to the unique stress profiles and environmental parameters encountered in low vacuum environments.

The significance of this research extends beyond academia, offering tangible solutions to industries grappling with the engineering challenges of constructing in extreme conditions. Ultra-high-speed transportation systems envisaged to operate within evacuated or near-vacuum tubes, such as hyperloop technologies, require pipeline materials that maintain structural integrity under reduced pressures and dynamic mechanical loads. Similarly, the construction of extraterrestrial habitats demands materials that resist microcracking and degradation stemming from vacuum exposure. Polymer fiber reinforced concretes demonstrating enhanced toughness and crack resistance align directly with these requirements, underscoring their potential transformative impact.

The deployment of acoustic emission technology represents a methodological advancement by enabling non-destructive evaluation (NDE) of concrete health during service life. Traditionally, deterioration within concrete structures is detected through surface observations or intrusive sampling, which may not capture early-stage damage. AE monitoring offers a continuous, sensitive metric capable of signaling damage onset beneath the surface. This capability is essential in low vacuum environments where external inspection is limited. The study’s integration of AE alongside mechanical testing provides a comprehensive framework for assessing and predicting the lifespan of fiber reinforced concretes under vacuum loading.

Moreover, the durability improvements observed via polymer fiber reinforcement have favorable implications for sustainability in construction. By enhancing concrete toughness and reducing crack formation, these composites can forestall premature structural failure, thereby diminishing repair frequency and resource consumption. The energy-intensive process of producing concrete and the associated environmental footprint are significant; extending service life through material innovation aligns with global goals for sustainable infrastructure development. This research, therefore, not only advances technical frontiers but also contributes to broader environmental objectives.

The research funding support by the Program Fund of Nonmetallic Excellence and Innovation Center for Building Materials highlights the strategic importance attributed to advancements in nonmetallic composites. Coordination between material scientists and structural engineers facilitates the translation of laboratory findings into viable commercial applications. Continued interdisciplinary collaborations and industrial partnerships are anticipated to accelerate the adoption of polymer fiber reinforced concrete in specialized infrastructures operating within demanding low vacuum contexts.

In conclusion, the pioneering work by Professor Long Guangcheng and colleagues establishes polymer fiber reinforced concrete as a viable, high-performance material tailored for low vacuum engineering environments. Through a combination of theoretical design, experimental verification, and advanced damage analysis, their findings illuminate pathways toward constructing resilient, durable infrastructure capable of thriving beyond Earth’s conventional atmospheric conditions. As humanity pushes the boundaries of transportation and space habitation, such material innovations will underpin the safety, reliability, and efficiency of future engineering marvels.

Subject of Research: Mechanical properties and damage mechanisms of polymer fiber reinforced concrete under low vacuum conditions

Article Title: Mechanical properties and damage analysis of polymer fiber reinforced concrete in low vacuum environments based on acoustic emission technology

Image Credits: Zhaofei Long

Keywords

Polymer architecture; Polymer fiber reinforced concrete; Low vacuum engineering; Acoustic emission monitoring; Structural material durability